Company’s Business Model

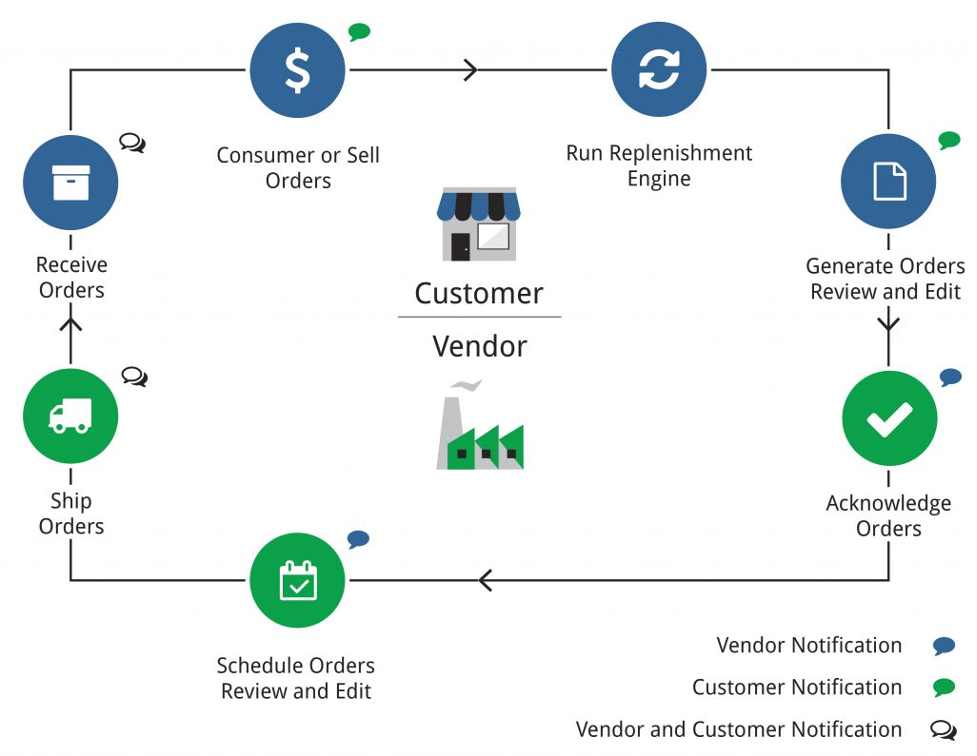

Walmart uses Vendor Management Inventory (VMI) business model as a strategic partnership between Walmart and its vendors that enables the vendor to manage inventory levels in Walmart stores. The model was designed to improve the supply chain’s speed, accuracy and efficiency. The VMI business model is based on a three-way partnership between Walmart, the vendor, and the vendor’s supplier. The vendor’s supplier delivers the products to Walmart stores on time. Walmart is responsible for providing the necessary resources and information to the vendor and ensuring that the inventory is replenished on time. Under the VMI model, Walmart and the vendor share responsibility for managing inventory levels in Walmart stores (Inventooly, 2022). Walmart provides the vendor with real-time sales data to assist the vendor in managing inventory levels. This data is used to develop forecasts of future product demand and determine when additional inventory needs to be replenished.

Diagram

Competitive Comparison

Walmart and Starbucks have different strategies when it comes to their supply chain. Walmart, the world’s largest retailer, has a low-cost, low-margin strategy reflected in its supply chain. Walmart has an extensive network of suppliers that allows it to negotiate for lower prices and pass on the savings to customers. It also has a sophisticated logistics network to keep its stores stocked with goods and ensure timely deliveries. Starbucks, on the other hand, has a product-focused supply chain strategy. The company has invested heavily in its supply chain to ensure its products’ quality, taste, and consistency. Starbucks has developed relationships with suppliers and farmers in the countries where its coffee beans are grown.

Starbucks excels in supplier relationships, logistics, and quality control. Starbucks has developed long-term relationships with its suppliers, allowing them to maintain consistent product quality. Furthermore, their logistics system allows them to move products quickly to their stores. Lastly, Starbucks has an extensive network of roasters and farmers worldwide, allowing them to source the highest quality ingredients and ensure that their products meet the highest standards. In contrast, Walmart excels in pricing, technology, and distribution. Walmart is known for its low prices and wide selection of products. This has been achieved by creating a highly efficient supply chain (The Wall Street Journal, 2023). They use advanced technology, such as RFID tags, to track inventory and ensure that products are always available.

Transportation Strategy

Walmart’s transportation strategy optimizes its supply chain and logistics operations to reduce overall costs and increase efficiency by leveraging technology, implementing a dedicated fleet, and utilizing third-party carriers. Walmart also utilizes specialized transportation management systems to improve visibility and communication and ensure efficient shipment routing. They also use transportation analytics to gain insights into their supply chain and identify areas for improvement. Walmart’s transportation strategy focuses on optimizing its supply chain and making it more efficient (Zhang et al., 2019). Walmart uses technology to track shipments in real-time and improve the speed and accuracy of its supply chain.

The company utilizes private and public transportation modes to move products from warehouses to customers. The company maintains a fleet of more than 10,000 trucks to transport large volumes of merchandise from its warehouses and distribution centres to its stores. The trucks are equipped with advanced tracking systems to ensure the timely delivery of products. Walmart also utilizes a variety of public modes of transportation, including rail, air, and water. Rail transport is cost-effective and allows Walmart to move large quantities of goods quickly and efficiently. Walmart also uses air transportation to move time-sensitive products such as fresh groceries and online orders. Air transport is a quicker and more reliable way to move goods, as it is not subject to weather or traffic conditions. Finally, Walmart utilizes water transport to move large volumes of goods. This mode of transport is mainly used for overseas shipments, as it is cheaper and more efficient.

Global challenges

Walmart faces numerous global supply chain challenges due to its vast size and global operations. These challenges include managing the complexity of its global supply chain network, dealing with complex regulatory and compliance requirements, managing supplier relationships and quality issues, competing with other global retailers, and dealing with increasing customer demands. One of Walmart’s leading supply chain risks is its reliance on overseas suppliers. Walmart has taken several measures, such as developing a global supplier diversity program, increasing supplier audits, and investing in technology to track better and manage its supply chain (Zhang et al., 2019). Walmart has also implemented several initiatives to strengthen its relationships with suppliers, including providing better training and support, encouraging sustainable practices, and offering incentives for suppliers that meet Walmart’s standards.

Economic and political factors highly impact Walmart’s transportation network. On the economic side, Walmart’s transportation network is heavily impacted by the cost of fuel, labour and materials. Rising fuel prices can increase the cost of transportation and make it difficult for Walmart to maintain its low prices. The cost of materials used in transporting goods, such as packaging and containers, can also impact Walmart’s transportation network. On the political side, Walmart’s transportation network is heavily influenced by government regulations and policies. For example, government regulations on emissions, safety and labour laws can impact Walmart’s transportation network. Government policies on trade agreements and tariffs can also affect Walmart’s transportation network.

Role of demand forecasting in the supply chain strategy

Demand forecasting helps Walmart determine the amount and type of products to stock in stores and the quantity and locations of warehouses and distribution centres. This helps to ensure that Walmart can meet customer demand while minimizing costs. Forecasting in times of uncertainty is a significant challenge for Walmart. Demand can change quickly due to external market forces, such as consumer preferences, economic conditions, and competitive pressures. According to Seyedan & Mafakheri (2020), demand forecasting can help Walmart manage uncertainty by providing a better understanding of the current and future market environment. By analyzing historical sales data, the company can identify patterns that can be used to predict future trends and anticipate shifts in demand. This helps Walmart adjust its inventory levels and supply chain operations to meet customer needs (Seyedan & Mafakheri, 2020). Demand forecasting can also help Walmart respond to unusual demand and market changes. By anticipating changes in the market, Walmart can adjust its inventory levels to meet unexpected demand.

Conclusion

Walmart’s supply chain strategy has enabled the company to become the largest retailer in the world. Through an efficient and effective supply chain, Walmart has offered low prices and a wide selection of products. The company has leveraged technology and advanced logistics to improve the speed and accuracy of its supply chain. Walmart has also invested heavily in its transportation strategy to reduce costs and increase efficiency. Furthermore, Walmart has implemented demand forecasting to help anticipate and respond to changes in the market and manage inventory levels. By leveraging its supply chain and transportation strategies, Walmart has been able to deliver on its promise of low prices and excellent customer service.

References

Capella University. (2022). Library. Capella University Library – Capella University. Retrieved January 26, 2023, from https://capellauniversity.libcal.com/

Inventooly. (2022). Walmart Inventory Management System. Inventooly. Retrieved January 30, 2023, from https://inventooly.com/blog/understand-walmart-inventory-management-process

Seyedan, M., & Mafakheri, F. (2020, July 25). Predictive big data analytics for supply chain demand forecasting: Methods, applications, and research opportunities – big data journal. SpringerOpen. Retrieved January 30, 2023, from https://journalofbigdata.springeropen.com/articles/10.1186/s40537-020-00329-2

The Wall Street Journal. (2023, January 20). Walmart CEO says companies should make sustainable products more affordable. The Wall Street Journal. Retrieved January 30, 2023, from https://www.wsj.com/livecoverage/davos2023/card/walmart-ceo-says-companies-should-make-climate-friendly-products-more-affordable-STltkIWF9pXscb5hIV0z?mod=Searchresults_pos19&page=1

Zhang, X., Wu, Y., & Zhang, Z. (2019, December 1). Vendor managed inventory system adaptability: A Supply Chain Management Analysis. Vendor Managed Inventory System Adaptability: A supply chain management analysis | Atlantis Press. Retrieved January 30, 2023, from https://www.atlantis-press.com/proceedings/febm-19/125924907

write

write