As an American-based and multinational retail corporation, Walmart has been known for its efficient supply chain management system that integrates well with appropriate methods and theories. It stated that Walmart’s supply chain strategy utilizes models like a financial model, network model, material logistics management model, and bottlenecks model to focus on direct long-term relationships with distributors, manufacturers, and omnichannel enterprises (Sheehan, 2019). All the mentioned models are combined with technology in their supply chain, which helps in automation, inventory tracking, and seamlessly restocking inventory (Fu, 2018). This has enabled Walmart to effectively serve over 50 countries with its widely spread 10,000-plus stores around the globe (Elder, 2019). According to Rickerby (2020), the success of Walmart’s supply chains has dramatically been associated with the small distribution system, defined inventory types, and streamlined supply chain operation. This effectiveness of their supply chain has resulted in a positive impact on the firm itself, as Volpe and Boland (2022) explain in terms of asset growth and low food price in the country they operate. However, the associated negative impact of its supply chain has been empirically proven to have a subtle effect on local employment, an increase in small business deletion, and a need for more dietary impact on the food they supply. Therefore, in this comprehensive evaluation, we are going to discuss the supply chain network of Walmart and its component using the existing data, and then based on its effectiveness, this analysis will present a swot analysis of the supply chain base on its strength, weakness, opportunity, and threats.

Discussion

The supply chain of Walmart

As a company with over 2 million associated workers worldwide, Walmart’s supply chain is one of the retail industry’s most significant operational and logistical triumphs. Berthold (2019) states that acknowledgment of the supply chain as an essential aspect of daily Walmart’s operation enabled low pricing and customer satisfaction. Also, the company knows that low pricing and customer satisfaction are associated with the appropriate integration of theories within their model for an efficient supply chain (Sheehan, 2019). For instance, logistics and procurement operation integrated models like a financial, network, and bottleneck model while purchasing, delivery, distribution, and return apply financial and network models within Walmart’s supply chain. Nonetheless, Walmart’s supply chain is shaped by tactics like cost modifications, price incentives, and the substitution of products to entice the purchasing power of the customers (Fu,2018).

Logistics and its models

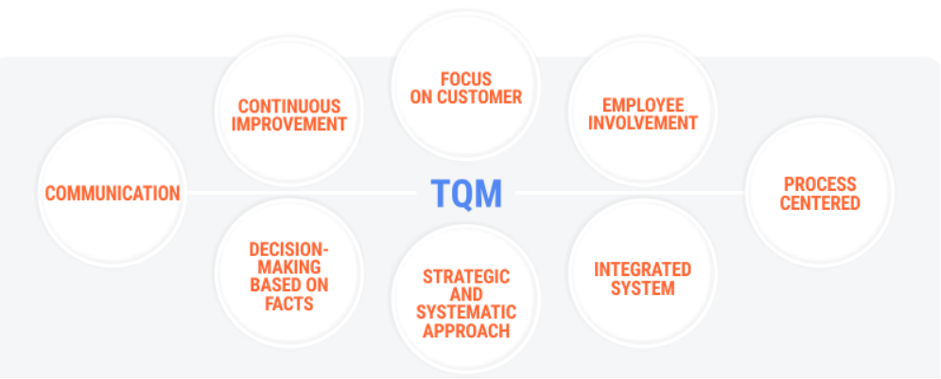

Logistics play a vital role as a component of Walmart’s supply chain. This is true, especially with the integration of the financial model and network model in its supply chain. Although logistics helps in information integration, packaging, and distribution, the two mentioned models help integrate theories like transaction cost analysis (TCA), channel coordination, material management and planning, total quality management, and theory of constraints and network perspective. For instance, through the financial model, the logistics play its role through theories like a) TCA, as shown below, helps determine the better price that will allow cheap pricing of its goods.

Transaction cost analysis chart adopted from Sheehan, 2019

b) channel coordination allows the supply chain to be manageable in every stage of its operations (that includes supplier, transportation, manufacturer, to retailers). Through the financial and network model, Walmart reduces overall cost and time.

Channel coordination chart adopted from Sheehan, 2019

Lastly, material management and planning as a theory cover the procedure from the raw material, supplier, and production to the customer. See the figure below. According to Sheehan (2019), this theory ensures that Walmart’s supply chain is steady and constant.

Channel coordination chart adopted from Sheehan, 2019

It is clear that Walmart’s logistics channels are effective due to the integration of financial and network models, which intern applies theories on TCA, channel coordination and material management, and planning to curb the logistics challenges that they had encountered in their initial expansion of lack of transportation that impacted the delivery of products and services at a discounted pricing. In the process, Walmart reduces per unit cost, and efficiency gains cost-effective distribution. This is because the logistics system becomes efficient and robust in its purpose, thus strengthening the logistics system.

Additionally, Berthold (2019) attributes the success of Walmart’s logistic system to prioritizing the cross-docking that enables the company to keep the inventory in motion. Through this innovative system, Walmart could transfer the products from the distribution center to the stores through complete packaging with less burden of the inventory system. Also, the company had strong ties with the suppliers who facilitated the packaging, standardization, and product labeling, which made the identification and distribution much more accessible.

Procurement operations.

Just like Logistics operation, procurement relies on theories like TCA, material management, planning, and channel condition. This is why it is true that the financial and network models are also applied in this component of Walmart’s supply chain. Walmart’s raw materials are collected from all parts of the world (Chiles & Dau, 2005); thus, its supply chain must rely on the Sheehan (2019) theories for its effectiveness. Additionally, the bottleneck model through the constraint theory allows the supply chain to be in continuous flow. This is due to the looping effect that the theory mandates. Sheehan contends that TQM theory enables Walmart’s supply chain to be streamlined from start to finish. The procurement results in a supply chain that emphasizes alignment, managing risk value-adding, and metrics. See the figure below.

Supply chain road chart adopted from Sheehan, 2019

As a result, Walmart’s procurement process utilizes negotiation on favorable terms with local and regional vendors and suppliers, allowing them to provide discounted or cheap products to their customers. The negotiators are guided by “your customer deserves the best price that you can get, don’t ever feel sorry for a vendor for he always knows what he can sell, and we want his bottom price” At the same the company spent a significant amount of time in meeting vendors and understanding their cost structure which allows them to make a transparent process and with the assurance that the manufacturers are giving their best on the cost-cutting. With each successful deal, Walmart establishes a long-term relationship with the vendor.

Distribution and return

Walmart’s distribution system relies on financial, network, and bottleneck models for its effectiveness, responsiveness, and flexibility in delivering goods from the docks to the stores. Also, through theories like channel coordination, the drivers are education for professionalism and continuous supply chain flow through proper inventory management that allows a smooth distribution flow and reduces the return of goods (Fu, 2018). However, according to Volpe and Boland (2022), the distribution system of Walmart is an innovation take that relies upon reducing lead time and paperwork, using bar codes for recoding inventory levels, and accessing the stock levels to serve as valuable data for the management which are then validated through TCA theory. Lastly, the sharing of point-of-sale information and cross-docking has been proven to have a vital role in the facilitation of the distribution system of Walmart (Negi & Anand, 2014). For instance, Walmart shares its point-of-sale information with Pampers, which helps predict the demand, thus allowing product distribution to be done in the early stages, thus improving the efficiency of the supply chain. However, in the scenario, Walmart identifies a problem in the distribution component, they seek a partnership with another organization. For instance, Fu (2018) explains that Walmart partnered with Gurobi optimization to fix the problem in its model as the classic mixed integer programming problem.

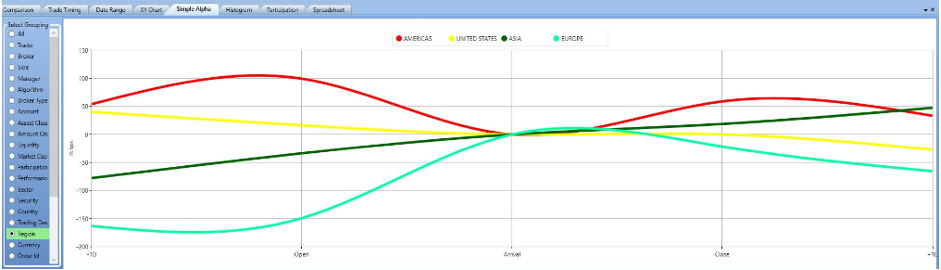

The return in Walmart’s supply chain can be based on the customer’s back to the company or the supplier. However, through total quality management theories, return in the supply chain is considered through reverse logistics. See the figure below.

TQM chart adopted from Sheehan, 2019

Being a typical case in the retail industry (Fu, 2018), Walmart has applied TQM to ensure that the above aspects have been considered, thus managing the return within the supply chain. On the supplier side, Walmart utilized its procurement procedure in selecting a suitable supplier who provides not only cheap raw materials but also quality for quality products.

Purchasing and Delivery.

Purchasing and delivery in Walmart have been adopting a financial model and bottlenecks model to integrate TCA and TQM theories to effectively invested in communication systems and IT for tracking merchandised inventories and sales and making purchasing more efficient across their stores, especially with their vast distribution of stores around the globe (Volpe & Boland, 2022). One of the ways a customer can purchase Walmart merchandise is through online channels that are always active and involved around the clock or by visiting the nearest store. Sheehan (2019) attributes the success of this purchasing channel to the financial model and bottlenecks model that allows proper inventory management that accelerates the delivery system, inventory keeping, and information cooperation among stores. Also, Volpe and Boland (2022) add that through the IT capability, inventories are made available to every store, thus reducing the overall inventory level while the suppliers are connected to a network of computers, thus ensuring product accessibility the shortest time in case of a purchase placed.

Further, through customer relationship management (CRM) theory, Walmart utilizes its number of stores widely spread across the globe for delivery (Sheehan, 2019). Through CRM theory, the firm can ensure loyalty retention, and maintain the storefront, just as shown in the figure below.

customer relationship management chart adopted from Sheehan, 2019

This ensures that the supply chain is maintained and running smoothly as the purchased product is distributed to the nearest location where the customer can collect it. Second, according to Rickerby (2020), the fleet of the tract has educated drivers on how to ensure and adhere to the inventory record keeping that ensures that the product is delivered to their respective store for the customer to pick at their continent time. Lastly, the point of sale sharing of information with the inventory management plays a vital role in ensuring that merchandise is delivered within the minimum time possible. End-of-sale information sharing allows the production of the future specific product demand where Walmart makes earlier distribution that makes the product available to be within the customer’s vicinity. Inventory management utilizes IT capabilities to maintain purchase orders, thus ensuring that everything is in order (Volpe & Boland, 2022).

Swot analysis

He et al. (2021) state that Walmart’s supply chain’s internal and external forces are never constant. However, the growth and the impact greatly depend on the steady ability to exploit the strength or opportunities in the industry to maintain the leading role in retaining the sector. Parker (2019) added that Walmart’s supply chain could be improved through the threat and weakness analysis, especially while venturing into the new market through omnichannel marketing. Therefore, understanding the swot analysis of Walmart’s supply chain is vital for revealing its competitive advantage, leading to successful growth and dominance in the retail industry.

Strength

The success of Walmart’s supply chain has been attributed to four main strengths that ensure its retail dominance. To begin, Walmart has a rich market experience that utilizes its organizational size, which allows efficiency in the high-volume production of a standardized product. Second, a sound customer and dealer network inventory system enables a mature demand-supply chain (He et al., 2021). This also helps provide excellent customer experience and proper record keeping that ensure continuous flow and effectiveness of purchases. Third is a good relationship with another enterprise that encourages market expansion through joint ventures and product distribution, thus allowing door-to-door delivery services (Parker, 2019). lastly, technology adoption helps improve the inventory management system and product purchase to make the general activity an involving experience.

Weaknesses

Walmart has a supply chain weakness that significantly impacts its operation. He et al. (2021) explains that the HRM practices of Walmarthaves some weakness in dealing with labor relation conflicts as the HRM utilizes policies that do not favor the employees. For instance, the company has been experiencing employee strikes in the US market due to these unfavorable policies. Also, the importation procedure of Chinese products into the US market negatively impacts Walmart’s gross margin performance or operational competence (Parker, 2019). Additionally, Jurevicius (2021) states that the company’s supply chain model can easily be copied, which can bring about a competitive difference, and that the online channel that the customer used in purchasing poor quality service. This is due to the claim that Walmart apps are not accessible in all areas around the globe, thus technically impacting customer-firm relationships.

Opportunities

Despite its extensive network, Walmart’s supply chain still has existing opportunities. According to Jurevicius (2021), comprehensive e-commerce applications and product diversification can be vital in the company’s supply chain system. This is because customer behavior is evolving as they seek faster and more reliable sources of their products. Also, with technological advancement, everything is becoming digitized. Product diversification presents an opportunity, especially during the covid-19 era when the grocery demand was high due to restriction of movement that could have benefited the firm with huge profits when integrating such services into their operation (Parker, 2019).

Threats

Walmart, as an international retailer, encounters several threats due to constant changing in the economy and threats in operations involved Walmart. These threats include the high cost of operation, growing competition, and local policy. Parker (2019) explains that the regional approach in China, like the preference of the Chinese government for the small and medium-sized retail industry in improving investment, posits a threat to Walmart’s operation. This encourages more and more competitors, primarily through online channels with various products and advanced logistics systems, than that Walmart. Thus, to maintain its place in the retail industry, Walmart incurs high costs in the general supply chain that make products at a high price.

Conclusion

In conclusion, Walmart’s efficient supply chain management system integrates well with appropriate models and theories. For instance, the financial, network, material logistics management, and bottlenecks models have been discussed on how they are integrated within Walmart’s supply chain. This enables the supply chain to utilize theories like transaction cost analysis (TCA), channel coordination, material management and planning, total quality management, and theory of constraints and network perspective for determining a better price that will allow cheap pricing of its goods and managing of every stage with the supply chain operations and maintaining steady operation for effectiveness, responsiveness, and flexibility. Lastly, the swot analysis presents that the supply chain of Walmart has rich market experience, a sound inventory system on customer and dealer networks, good relationships with other enterprises, and technology adoption as strengths. At the same time, the weakness includes unfavorable employee policies, importation procedures between China and US, and an easily copied supply chain model (He et al., 2021). This is accompanied by threats like the high cost of operation, growing competition, and local policy (Parker, 2019). However, the identified opportunities included e-commerce application and product diversification, which, when incorporated into their supply chain, could help maintain their retailing competence (Jurevicius, 2021).

Reference

Berthold, K.R. (2019). Supply Chain Management: A Descriptive Conception. International Journal for Empirical Education and Research, 3(19), 43–65.

Chiles, C.R. and Dau, M.T., (2005). An analysis of current supply chain best practices in the retail industry with case studies of Wal-Mart and Amazon—Com (Doctoral dissertation, Massachusetts Institute of Technology).

Dong, R., (2023). Wal-Mart’s Financial Analysis. Highlights in Business, Economics and Management, 5, pp.312–316.

Elder, S.D., (2019). The impact of supermarket supply chain governance on smallholder farmer cooperatives: the case of Walmart in Nicaragua. Agriculture and human values, 36(2), 213–224.

Fu, M. (2018). Data Science In Walmart Supply Chain Technology. [online] Medium. Available at: https://medium.com/walmartglobaltech/data-science-in-walmart-supply-chain-technology-bdb5d6b4105c.

Ghosh, D. and Shah, J., (2015). Supply chain analysis under green sensitive consumer demand and cost-sharing contract. International Journal of Production Economics, 164, pp.319–329.

He, Z., Ding, Y. and Liu, W., 2021, September. The States Quo of Walmart and Challenges and Opportunities of Their Online Transformation in China Based on SWOT Analysis. In 2021 International Conference on Financial Management and Economic Transition (FMET 2021) (pp. 353-359). Atlantis Press.

Jurevicius, O. (2021). Walmart SWOT Analysis (5 Key Strengths in 2021). [online] Strategic Management Insight. Available at: https://strategicmanagementinsight.com/swot-analyses/walmart-swot-analysis/.

Negi, S. and Anand, N., (2014). Green and Sustainable Supply Chain Management Practices-A Study of Wal-Mart. Emerging Business Sustainability, pp.141–157.

Ofori-Nyarko, N.S., Wang, F. and Annoh, W.O., SWOT ANALYSIS: WAL-MART STORES INC.

Parker, B. (2019). Walmart SWOT Analysis 2019 | SWOT Analysis of Walmart | Business Strategy Hub. [online] Business Strategy Hub. Available at: https://bstrategyhub.com/swot-analysis-of-walmart-2019-walmart-swot-analysis/.

Rai, P., INTERNATIONALIZATION CHALLENGES: INSIGHTS FROM WAL-MART’S GLOBAL EXPANSION. GLOBAL JOURNAL OF BUSINESS MANAGEMENT, p.38.

Rickerby, M. (2020). Walmart Supply Chain: Winning At Inventory Logistics. [online] www.extensiv.com. Available at: https://www.extensiv.com/blog/supply-chain-management/walmart.

Sheehan, B. (2019). The Different Types of Supply Chain Management Methods and Theories. [online] Hollingsworth. Available at: https://www.hollingsworthllc.com/the-different-types-of-supply-chain-management-methods-and-theories/.

Volpe, R. and Boland, M.A., 2022. The Economic Impacts of Walmart Supercenters. Annual Review of Resource Economics, 14, pp.43-62.

Walmart (2022). About. [online] Corporate – US. Available at: https://corporate.walmart.com/about#:~:text=We%20are%20creating%20opportunities%20and.

write

write