List of Abbreviations

| Abbreviation | Meaning | Definition |

| AI | Artificial Intelligence | Artificial intelligence alludes to the intelligence of software or machines. |

| INC | Incorporated | It alludes to an incorporated company that is recognised as a legal entity different from its members. |

1. Introduction

Initially, companies tried different strategies aimed at reorganising and restructuring their supply operations in order to improve the level of the supply chain effectiveness and meet the continuously changing customer needs. However, most of the companies did not manage to achieve their primary objective of attracting customer loyalty and expanding their customer base through the application of the strategies (Tien et al., 2019). The modern business environment, therefore, demands that companies prioritise adopting a competitive approach to make their supply chain better to address the changing demand and preferences of modern customers. (Farida and Setiawan, 2022), Expounded on this in the statement, “Modern businesses must continuously invest in high quality, innovative, and highly responsive systems in their supply chain operations to have a competitive advantage over their rivals,”‘ which means that the companies must pursue superiority in performance in their supply chain operations through ensuring they have adequate resources. They invest in exceptional competencies in their supply chain. A competitive strategy in the supply chain alludes to the approach adopted by a company to address and meet the needs of the customers. The main focus of the supply chain strategy is the system of production, distribution system, and processes, the methods of transport, and the nature of procurement and how they can be improved to ensure customer satisfaction. The final part of the report is a recommendation on additional strategies that Walmart Inc. should adopt and implement to make its supply chain system and operations more competitive.

Literature Review

2.1Competitiveness in Supply Chains

Competitiveness in the supply chain as the ability that a company’s supply chain has to deliver value to its customers based on their needs, which gives it a competitive advantage over its rivals in the market. In the modern business environment, companies with competitive supply chains have an added advantage over others as they take prominence as compared to other abilities of companies. According to (Mukhtar, 2015), the rivalry between firms is now focused on the capabilities of their supply chains and not on the firms themselves. The interactions between companies in relation to the financials, information, and the flow of goods create certain perceptions and expectations on the ability of the firms and the value derived from such interactions by the parties involved. The main concern of the parties is on the quality and the value of services provided whether it involves a forward or reverse flow (Mukhtar, 2015). Therefore, service quality explains the capability and the value of a company’s supply chain and, hence, its competitiveness.

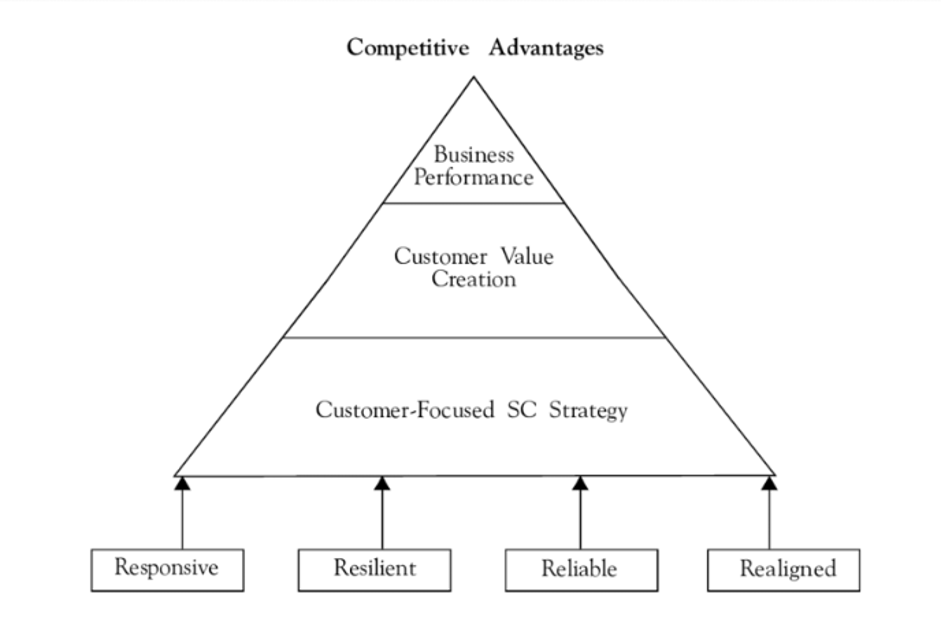

According to (Farida and Setiawa, 2022), the competitive ability of a company is determined by the strategic position it has in the market in terms of the application of efficient logistic systems to achieve operational efficiency. It alludes to how the company manages the flow of its operations to ensure its supply chain offers value to the customers. To gain a competitive advantage, companies need to have well-developed relationships with partners in the supply chain to ensure efficient management of the flow of materials between suppliers and end customers. (Qi et al., 2017), states that the development of a supply chain strategy requires the integration of the management commitment, the supply chain processes, and the supply chain objectives. Gaining a competitive advantage in the supply chain requires collaboration, synergy, and coordination between the parties involved in the supply chain process of a company (Qi et al., 2017). Therefore, to build a competitive supply chain, the strategy adopted must stay in line with the overall strategy of the company.

According to (Sarfraz et al., 2023), globalisation, advanced technology, and development in information technology and its use in businesses enable companies to strategically focus on incorporating supply chain competitiveness into their strategy to improving on their competitive ability. It requires refining a company’s business operations, reengineering, renovating, and getting into alliances with other players involved in the supply chain processes and operations (Sarfraz et al., 2023).

2.2 Adoption and Development of Competitive Supply Chains

The hyper-competitive market environment demands the adoption and development of competitive supply chains for companies to survive, retain their markets, and increase their market base. Companies attain competitiveness in their supply chain by ensuring efficient delivery, optimal facility utilisation, short lead times, quick responsiveness, customer satisfaction, and profitability. Consequently, to attain a higher competitive ability, the supply chain processes and operations of a company require inputs such as customer and process orientation, synergy, customisation, agility, collaboration, coordination, strategic alliances, cooperation, and demand management. A competitive supply chain results in innovation, agility in response, customer value, improvement, and customer satisfaction, which determines the level of competitive ability of a company (Naqvi et al., 2020).

(Rogers, 2016), shows that the rapid technology developments go hand in hand with the growth of the global market and fierce competitition between companies operating in the global scene. Advanced technology has led to improved transportation and communication thus better organised, more efficient, and effective global operations. The improved flow of communication creates a better balance between demand and supply in the global market. (Wu et al., 2016), states that the primary goals achieved through creating efficiency in a company supply chain are savings in the cost of the supply chain operations, improved supplier relationships, and improved sales volume. Dell and Walmart were the pioneers among companies that managed to attain a competitive advantage by developing efficient supply chains. The two companies managed to use the strategy to stay ahead of the competition in their industries between 1970 and 1980 (Hugos, 2016).

Figure 1: Customer-Centric Supply Chain (Madhani, 2017)

2.3 Role of Technology in Achieving Competitive Supply Chains

However, (Haque et al., 2023) show that companies in the modern business world are in a better place due to the opportunity to capitalise on the use of technology to achieve operational efficiency in their supply chain operations. It is vital therefore for modern companies to focus on supply chain planning to achieve a competitive advantage through ensuring they carry out their supply chain planning in real time. It is possible through the application of supply chain analytics that enable access to real-time data. The real-time access enables analysis of bulk volumes of data, thus making it easy for the companies to make accurate predictions and make changes to their supply chain processes based on the changing needs of the customers. (Uddin, 2022), states that the supply chain strategy of a firm should focus on ensuring collaboration between the suppliers, the distributors, and the vendors. The collaboration of the different players involved in the supply chain process maximises the value offered to the customers, thus increasing the level of customer satisfaction achieved by a company (Uddin, 2022).

According to (Tho, 2018), companies need to have good relationships with the suppliers for them to have good relations with the customers. Successful suppliers and distributors result in a better ability of a company to address and adequately meet the needs of the customers (Tho, 2018). Therefore, the level of effectiveness of a strategy in supply chain management is determined by the level of collaboration with the stakeholders.

Based on the studies conducted on the topic a gap exists due to the narrow focus of the previous studies on logistics, supplier, and distribution while examining how firms compete using their supply chain. The studies have ignored the different dimensions of service quality in the company’s supply chain, which ensures the delivery of value to the customers (Foster and Gardner, 2022). It is therefore essential to consider further investigations on the different service quality dimensions that are applied by companies to develop more competitive supply chains.

Case Company – Walmart Inc.

Walmart Inc is US based retailer involved in the operation of hypermarkets, supermarkets, neighbourhood markets, supermarkets, grocery stores, and discount stores. The company’s headquarters are in Bentonville, Arkansas, in the USA. The company uses licensed brands and private labels such as Onn, George, and Wonder Nation to market products. Walmart Inc. uses e-commerce portals to merchandise its products in America, Asia, and Africa (Walton, 2020).

The Mission and Values of Walmart Inc

The mission of Walmart Inc. is “Save money, live better,” which shows that the company aims to make the lives of its customers better by offering quality products and services at reasonable prices. The value of the company includes working towards achieving excellence and correctly predicting the needs and wants of the customers to meet and exceed their demands. The company aims to capitalize on the use of technology to take advantage of the e-commerce platforms to exceed the needs of the customers by reaching excellent levels of customer satisfaction.

Market and reach of Walmart Inc

Walmart Inc. is the world’s leading retailer with operations in 24 countries, where it operates more than 10,623 supercenters, discount stores, and neighbourhood markets. As of 2022, Walmart Inc. was among the top 100 stores in the US in terms of e-commerce net sales and report sales. As of 2023, it had the largest market share in the US among online retailers. The company currently has a market share of 6.3% in the US, more prominent than Apple Inc., which has a market share of 3.9%, eBay with 3.5%, and Target with 2.1% (Sindhu et al., 2023).

Walmart Inc. Leadership and Advantage

Walmart Inc. uses the transactional leadership style, with a hierarchical structure of leadership that follows precise levels of responsibility and authority. At the top, the company has executive leadership, followed by senior management, and department heads. Walmart Inc has an advantage due to its optimization of supply chain and cost control which enables it to have an advantage over the competition. The company has attained a unique capability to effectively manage its global supply chain at reasonable costs which gives it a competitive advantage over the competition (Pandey et al., 2021).

Walmart Inc Competitive Advantage

Walmart Inc. has attained a competitive advantage due to the high level of efficiency in its supply chains. The company also uses advanced technology to create a better experience for the customers and also charges competitive prices for its products and services. The company has attained a competitive advantage due to its optimized supply chain, and its effective management of inventory. The company has managed to capitalize on the use of technology to address customer demands, at very reasonable prices. The company has managed to create value for the customers thus attracting customer loyalty and expanding the customer base in the US and the global market (Velez Berrios, 2020).

Recent Highlights

Walmart Inc. has made investments in its inventory management system to make it Artificial Intelligence (AI) powered to meet customer demands adequately and more effectively. The investment is meant to adequately and quickly respond to customer demands during the peak shopping seasons. The AI-powered system enables quick detection of the speed of movement of products. It automatically sends signals to deliver more products to meet the demand and avoid inconveniences to the customers. Walmart Inc has also invested in the expansion of the application of advanced technology in the company’s distribution centers globally, as of 2023. More than 15% of the company’s stores in its global markets benefitted from the investment by receiving products from automated distribution centers (Venkatesan, 2021).

Amazon Inc. Financial Performance

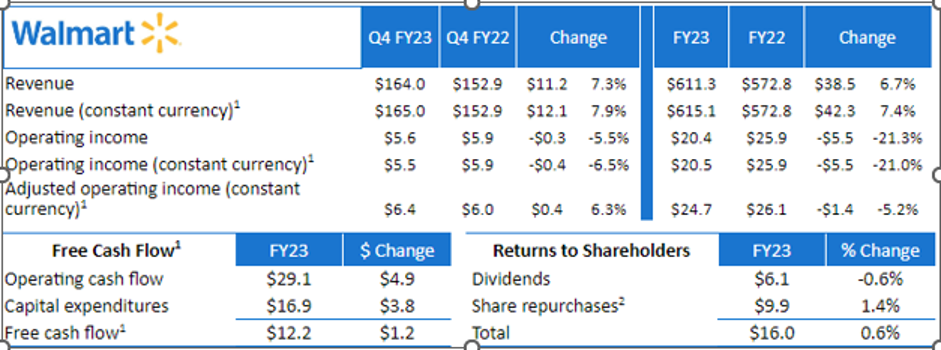

Walmart Inc’s revenue for the year 2023 grew by 6.7% to $611.3 billion as compared to the revenue in 2022. The company sales in the US market increased by 6.6% for the financial year 2023. Walmart Inc generated operated capital amounted to $29.1 billion and made share repurchases and dividend payments totaling $16 billion (Dong, 2023).

Figure 2: Walmart Inc Financial Performance Year 2023 (Dong, 2023)

Challenges and Relevance

Walmart Inc. is a large retailer with a broad global reach and thus faces multiple challenges in its supply chain management and operations. The landscape and the supply, chain have become more complicated thus challenges in the company’s effort to navigate and at the same time create more convenience and efficiency for the customers. Firstly, the company operates on a large scale with operations in 24 countries where it operates about 10,000 stores. The scale of operations presents challenges in the management and coordination of goods to ensure they reach customers in good time and at a low cost. The challenge is also more complex due to the company’s global network of suppliers, stores, and distribution centers (Bal and Pawlicka, 2021). The challenge is relevant as the company must ensure it overcomes the challenge to continue offering more convenience and efficiency for the customers and still charge competitive prices to improve on its competitive ability and retain its leading position in the market. Otherwise, ignoring the challenge might result in the company losing the competitive advantage it has due to its effective supply chain management.

Secondly, Walmart Inc faces challenges in the management of the supply chain due to its dealings with multiple suppliers in different countries and a vast number of products. There are difficulties in the management of the supplier relationships to ensure they are on the same page and ensure the company continues providing high quality and best prices for the customers. Companies are required to achieve a high level of sophistication in their supply chain processes and operations to track and manage the performance of their suppliers (Bal and Pawlicka, 2021). The challenge is relevant as Walmart Inc. is required to put extra effort to ensure its supply chain operates at a more sophisticated level to continue offering value to the customers and exceeding their expectations to maintain and improve on its competitive ability which relies significantly on the efficiency and superiority of the supply chain.

Discussion

4.1 Competitive Advantage of Walmart Inc Supply Chain

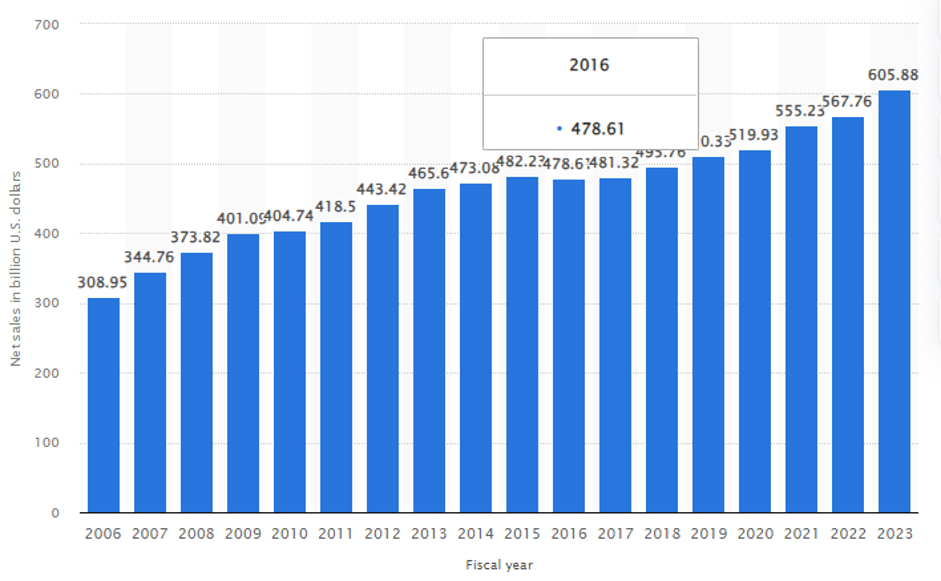

Walmart Inc. has managed to develop one of the best supply chains globally due to its high level of efficiency. The company’s capabilities in terms of logistics and making products available to customers are exceptional as compared to other companies in the global scene. The abilities of the company’s supply chain have enabled the company to grow its customer base in its global market. Walmart Inc.’s supply chain efficiency has had a significant contribution to making it the leading retail company globally. The company’s customers are assured of getting anything they need and getting it delivered on time (Lin, 2019)

The supply chain system used by Walmart Inc. offers benefits to both its customers and suppliers. They are assured of efficiency in supply chain operations. The system has taken into account the entire inventory process, shipping, warehousing, delivery, and pricing of the products. Walmart Inc. has made some special efforts to ensure all its supply chain operations are as smooth as possible in spite of the challenges encountered in the supply chain operations (Jawad, 2017).

Walmart Inc. has managed to capitalise on the use of modern advanced technology to manage orders, thus enhancing the effectiveness of the supply chain. The use of advanced technology in the company’s supply chain enables the company to reduce the cost incurred in supply chain operations significantly. Also, technology increases the delivery speed and improves the level of efficiency of the company’s supply chain. In 2021, the company made an investment of $14 billion in the automation of its supply chain. It included the automation of the control and management systems used in its warehouse. It also invested in the automation of sorting and picking in its warehouses. It has dramatically helped to reduce the number of staff and warehouses, thus a reduction in the general overall costs. It translates to charging competitive prices to the customers and offering better quality services.

The primary orientation of Walmart Inc. is to meet the needs of the customers efficiently. Therefore, the company is always focused on continuous supply chain innovations and improvements to increase the level of customer satisfaction and thus keep the company ahead of the competition. The company has made considerable investments in its resources to ensure that its supply chain is organised and managed, which makes it different and superior to the competition. The management of the supply chain is essential, especially by taking advantage of technological advances, as it helps in positively improving the level of customer satisfaction (Raj et al., 2023).

Walmart has achieved extraordinary competitive ability through its supply chain by ensuring that it deals directly with the manufacturers and avoids the distributors. It enables the company to reduce the overall cost and overcome the challenges that may arise due to dealing with many middlemen that increase the level of efficiency and value offered to customers (David ad Adida, 2015).

Figure 3: Growth in Walmarts Net Annual Sales (2006 to 2023) (Oxford Analytica, 2023)

Walmart Inc’s supply chain has critical components that work together to achieve high efficiency in the supply chain operations, thus enabling the company to offer better customer service as compared to the competition. Vendor management is among the vital components of the company’s supply chain and focuses on ensuring the company relates well with suppliers and collaborates to achieve mutual benefits. Collaboration with vendors gives the company a better chance to negotiate for high-quality standards, cheaper prices, and fast delivery times. Another vital component in the success of Walmart Inc.’s supply chain is the accuracy of demand prediction using data-driven models and analytics. It enables the company to use market trends and sales data to anticipate demand changes. Inventory optimisation is also a vital component that involves the application of different techniques to balance inventory costs and product availability. Walmart Inc. has invested in sophisticated systems for inventory management to monitor the level of stocks and the movement of stocks, thus quickly identifying obsolete and slow-moving products (Jawad, 2017).

Relevant Theories

5.1 The Customer Value Theory

Customer value theory alludes to the perception of a customer on the experience associated with a particular company or brand. It plays a vital role in improving the satisfaction of the companies thus attracting customer loyalty. According to the theory, the survival of a company in the industry depends on the value of services and the level of satisfaction of its customers. The theory applies in supply chain management as it is essential to focus on customer value in a company’s supply chain management by giving time advantages and charging competitive costs to attract and retain customers. The theory requires companies to focus on market orientation and process orientation to stay ahead of the competition (Potra et al., 2018).

Companies manage to achieve competitiveness through their supply chains by enhancing their value delivery capabilities to have an edge over the supply chains of the competition. Walmart Inc. has invested in a value supply chain that integrates quality, speed, cost, and flexibility of the supply chain to create value for the customers, thus making it possible for the company to use its supply chain to gain a competitive advantage (Jawad, 2017).

5.2 Value Chain Theory

There is a direct link between the value generated by a company’s supply chain networks and the value derived by the customers. A company cannot deliver value to its customers if it is not factored into its supply chain operations. According to Michael Porter’s value chain, value creation requires cross-functional integration and networks between all the stakeholders in the supply chain (Kumar and Rajeev, 2016). According to (Simons, 2019), companies gain a competitive advantage through the differentiation of their operations, charging lower prices, thus creating value for the customers. The value for the customers is created creation of value both downstream and upstream thus, it involves the value chain of the distributors and the value chain of the suppliers. Walmart Inc. has successfully managed to apply the value chain theory in its supply chain operations by ensuring every step adds to the value offered to the end customer (Flamand et al., 2020).

Strengths and Weaknesses of the Case Study

The case study provides deeply investigated and explored information on the supply chain management of Amazon Inc., the competitive ability of the company’s supply chain, and the factors that make its supply chain offer the best value to the customers. Also, the case study provides relevant information that enables researchers interested in the supply chain operations and management of Walmart Inc. to carry out further research on the company’s supply chain operations. On the other hand, it is hard to replicate the study on another company due to its only focus on the supply chain management and operations of Walmart Inc..

Conclusion

In summary, a competitive supply chain gives companies the ability to attract customer loyalty by offering customers value for money. It boosts the image of the company in both local and international markets. Modern firms have shifted their rivalry to the competitive ability of their supply chain operations. A company gains a competitive ability by positioning itself strategically through the adoption of efficient logistic systems in its supply chain management and operations. It involves developing good relationships with other stakeholders in the supply chain operations of the company which enables efficient management to ensure a smooth flow of materials between the comp any suppliers and the customers. Globalisation and advanced technology have enabled firms to capitalize on the use of information technology to strategically incorporate the competitive ability of their supply chain in the company’s business strategy. Walmart Inc. has managed to operate within its mission and values to become a customer-centric company by investing in its supply chain operations to create value for its customers.

Recommendations

To make Walmart Inc’s supply chain more competitive, the company should give priority to making more investments in real time planning of its supply chain operations and systems. The investment will help the company to adequately and timely respond to to changes in the business landscape. The investment in the supply chain analytics solution will enable more efficient supply chain management by providing real-time data on the entire supply chain process thus enabling quick reaction thus always staying ahead of the competitors in terms of addressing changing customer needs and achieving high customer satisfaction (Gopal et al., 2022). The company has the financial ability to invest thus can achieve this in the next year by involving experts and and proven industry leaders to identify and make strategic investments.

Secondly, Walmart Inc. should also make more investments in innovation and the adoption and use of advanced technology to continue creating a better experience for the customers. The company should focus more on bringing in better automation solutions which will play a critical role in the elimination and reduction of errors and minimise the time required between ordering and delivering to the customers, thus further improving the efficiency of the company supply chain (Gurtu and Johny, 2021). The company can achieve this in the next two years by engaging experts in technology and funding research projects aimed at identifying and incorporating the use of advanced and effective technology in its supply chain management and operations.

Reference List

Bal, M. and Pawlicka, K., 2021. Supply chain finance and challenges of modern supply chains. LogForum, 17(1), pp.71-82.

David, A. and Adida, E., 2015. Competition and coordination in a two‐channel supply chain. Production and Operations Management, 24(8), pp.1358-1370.

Farida, I. and Setiawan, D., 2022. Business strategies and competitive advantage: the role of performance and innovation. Journal of Open Innovation: Technology, Market, and Complexity, 8(3), p.163.

Flamand, O.J., Wisher, A. and Riley, S., 2020. Strategic Plan: Amazon.

Foster, S.T. and Gardner, J.W., 2022. Managing quality: Integrating the supply chain. John Wiley & Sons.

Gopal, P.R.C., Rana, N.P., Krishna, T.V. and Ramkumar, M., 2022. Impact of big data analytics on supply chain performance: an analysis of influencing factors. Annals of Operations Research, pp.1-29.

Gurtu, A. and Johny, J., 2021. Supply chain risk management: Literature review. Risks, 9(1), p.16.

Haque, A.K.M., Waqar, K. and Dehkordi, P.K.H., 2023. The Significance of Digital Transformation in the Supply Chain Management for Facilitating International Businesses: Cases from Emerging Markets.

Hugos, M.H., 2018. Essentials of supply chain management. John Wiley & Sons.

Jawad, S., 2017. A literature analysis of Walmart’s supply chain excellence in term of integration, distribution and operations.

Kumar, D. and Rajeev, P.V., 2016. Value chain: a conceptual framework. International journal of engineering and management sciences, 7(1), pp.74-77.

Madhani, P.M., 2017. Customer-focused supply chain strategy: Developing business value-added framework. The IUP Journal of Supply Chain Management, 14(4), pp.7-22.

Mukhtar, U., 2015, May. Supply chain competitiveness with the perspective of service performance between supply chain actors: A theoretical model. In Managing Intellectual Capital and Innovation for Sustainable and Inclusive Society: Managing Intellectual Capital and Innovation. Proceedings of the MakeLearn and TIIM Joint International Conference (Vol. 2).

NAQVI, M.H., ASIM, D.M. and MANZOOR, S., 2020. Analysing the impact of supply chain agility on customer satisfaction through responsiveness and innovation. CenRaPS Journal of Social Sciences, 2(1), pp.26-40.

Oxford Analytica, 2023. US s-commerce will grow fast, following Asia’s lead. Emerald Expert Briefings, (oxan-db).

Pandey, R., Dillip, D., Jayant, J., Vashishth, K., Nikhil, N., Qi, T.J., Kee, D.M.H., Mei, T.C., Xin, R.Y.K. and Qhi, L.Y., 2021. Factors Influencing Organization Success: A Case Study of Walmart. International Journal of Tourism and Hospitality in Asia Pasific (IJTHAP), 4(2), pp.112-123.

Potra, S., Pugna, A., Negrea, R. and Izvercian, M., 2018. Customer perspective of value for innovative products and services. Procedia-Social and Behavioral Sciences, 238, pp.207-213.

Qi, Y., Huo, B., Wang, Z. and Yeung, H.Y.J., 2017. The impact of operations and supply chain strategies on integration and performance. International Journal of Production Economics, 185, pp.162-174.

Rodrigue, J.P., 2020. The distribution network of Amazon and the footprint of freight digitalization. Journal of transport geography, 88, p.102825.

Rogers, D.L., 2016. The digital transformation playbook: Rethink your business for the digital age. Columbia University Press.

Sarfraz, M., Khawaja, K.F., Han, H., Ariza-Montes, A. and Arjona-Fuentes, J.M., 2023. Sustainable supply chain, digital transformation, and blockchain technology adoption in the tourism sector. Humanities and Social Sciences Communications, 10(1), pp.1-13.

Simons, R., 2019. The role of management control systems in creating competitive advantage: new perspectives. In Management Control Theory (pp. 173-194). Routledge.

Sindhu, M., Qureshi, T.M., Singh, S. and Banday, S.H., 2023. Digitisation in retailing: the game-changing driver of industrial transformation. International Journal of Intellectual Property Management, 13(1), pp.22-39.

Tien, N.H., Anh, D.B.H. and Thuc, T.D., 2019. Global supply chain and logistics management.

Tho, N.D., 2018. Firm capabilities and performance: A necessary condition analysis. Journal of Management Development, 37(4), pp.322-332.

Uddin, M.B., 2022. The effect of strategic commitment and supply chain collaboration on operational and innovation performance. IIMB Management Review, 34(4), pp.364-377.

Vélez Berríos, L., 2020. Walmart’s Successful Business Strategies Leading to Competitive Edge in the Retail Industry. Manufacturing Competitiveness.

Venkatesan, S., 2021. How walmart is using AI to make smarter substitutions in online grocery orders. Retrieved May, 29, p.2022.

Walton, S., 2020. History of Walmart. Made in America. Our format.

Wu, L., Yue, X., Jin, A. and Yen, D.C., 2016. Smart supply chain management: a review and implications for future research. The international journal of logistics management, 27(2), pp.395-417.

write

write