Introduction

AMEC Maritime Construction is a global corporation that plans and constructs a broad range of maritime projects for clients all over the globe. The company operates shipyards all around the world and is well-known for its ability to complete high-quality projects on schedule and on budget. The goal of this study is to look at the design and installation of an offshore oil and gas production platform for an international collaboration. The report will focus on project management, budgeting, and timetables, as well as the processes involved in the creation and implementation of the platform. Furthermore, the report will examine the qualifications and expertise of the project manager and project team, as well as the project plan that has been prepared for the project. The offshore oil rig platform in the North Sea will be made up of two four-leg jackets, one for production and one for accommodation. The project has a £550 million budget, and the platform must be finished by August 30th, 2024, when the winter weather closes in. If the project is not completed by the deadline, there is a £300,000 per day operational loss profit penalty. The project, which is set to begin in the first half of 2021 at AMEC’s shipyards in Newcastle upon Tyne, will need a 24-hour workload structure as well as the use of significant subcontractors from the United Kingdom and Europe.

Construction

Description of the construction project

The offshore oil rig platform construction project entails building two four-legged platforms, one for production and the other for accommodation. The production structure will house the production decks and equipment, while the accommodation structure will house and work for the personnel (Durant, 2014). A five-level accommodation (Deck) platform for staff quarters and offices, as well as a four-deck production (Deck) platform for production equipment, will also be built as part of the project. These components will be produced at AMEC’s shipyards in Newcastle upon Tyne, using significant UK and European subcontractors and the 24/7 workload framework (Durant, 2014).

Two four-leg jackets

- Production platform jacket: The production platform jacket is a structural component of the offshore oil rig platform that supports the production decks and equipment (Bargi et al., 2011). It comprises four legs anchored to the seabed and provides stability for the platform. The legs are made of steel and are designed to withstand the harsh conditions of the North Sea, including high winds, waves, and currents. The jacket also includes the equipment and systems for oil and gas production, such as drilling equipment, wellheads, and production facilities.

- Accommodation platform jacket: The accommodation platform jacket is a structural component of the offshore oil rig platform that provides support for the crew quarters and offices. Like the production platform jacket, it is composed of four legs anchored to the seabed, providing stability for the platform. The legs are made of steel and are designed to withstand the harsh conditions of the North Sea (Bargi et al., 2011). The jacket also includes the necessary facilities and systems for the crew’s accommodation, such as living quarters, offices, and recreational areas.

One accommodation (Deck) platform

The accommodation (Deck) platform is a structural component of the offshore oil rig platform that provides the crew members’ living quarters and office spaces. It is built on top of the accommodation platform jacket and has five levels, including sleeping quarters, dining areas, recreational areas, offices, and other necessary facilities for the crew members. The platform is also designed to provide the crew with a safe and comfortable living environment. The platform is built using corrosion-resistant and fireproof materials to ensure safety and durability.

One production (Deck) platform

The production (Deck) platform is a structural component of the offshore oil rig that houses the production equipment and facilities. It is built on top of the production platform jacket and is designed with four decks to accommodate the production equipment, such as drilling equipment, wellheads, production facilities, and control rooms (Wu & Li, 2022). The platform is also designed to withstand the harsh conditions of the North Sea and provide a safe and efficient working environment for the production team. The platform is built using corrosion-resistant and fireproof materials to ensure safety and durability. It also includes safety features such as emergency shutdown and fire suppression systems. The platform has the necessary communication, power, control, and other support systems to produce oil and gas.

Installation

Jackets: Skidded onto barges and Towed to North Sea oil field location

The installation of the jackets is a critical part of the offshore oil rig platform project. Once the construction of the two four-leg jackets, one for the production platform and one for the accommodation, is completed, they will be skidded onto two barges. The barges will then tow the jackets to the North Sea oil field location, where the platform will be installed. The skidding process involves using specialized equipment and cranes to move the jackets from the shipyard to the barges. This process is carefully planned and executed to ensure that the jackets are securely loaded and transported to the installation site without damage (Wu & Li, 2022). Once the jackets reach the North Sea oil field location, they will be anchored to the seabed using piles and other specialized equipment. This process is also carefully planned and executed to ensure that the jackets are securely anchored and able to withstand the harsh conditions of the North Sea.

Platforms: Towed out to jackets location

After the jackets have been securely moored in the North Sea oil production site, platforms will be placed onto barges and delivered to their position. The housing platform will have five levels of employee quarters and offices, whilst the production platform will have four decks for manufacturing equipment. This process is similar to the installation of the jackets and requires the use of specialized equipment and cranes to load the platforms onto the barges and transport them to the site of installation. Once the platforms reach the jacket’s location, they will be lifted and installed onto the jackets using specialized cranes and other heavy equipment. This process is carefully planned and executed to ensure that the platforms are securely installed and able to withstand the harsh conditions of the North Sea. The installation process also includes preparing and installing subsea pipes and testing the platform systems to ensure that they are fully operational.

Project Manager and Team

Melvin Black, Project Manager

Melvin Black has been appointed as the project manager for the offshore oil rig platform project. He is a 50-year-old project manager with 30 years of experience in marine engineering project management. Melvin has a proven track record of delivering high-quality projects on time and within budget and has the necessary qualifications and experience to lead this complex project. Melvin Black has a marine engineering degree and 30 years of experience in the field. He has worked on various marine engineering projects, including oil rig platform projects. He has the qualifications and experience to lead the project and ensure it is completed on time and within budget. Melvin Black has appointed a full-time team of five managers and ten assistant managers to work on the project. The team is structured as follows:

| Position | Team Member |

| Account Manager | John Montgomery |

| Transportation & Installation Manager | Jane Smith |

| Jacket Manager | Michael Brown |

| Operation Platform Manager | Mary Johnson |

| Accommodation Platform Manager | David Davis |

| Assistant Manager for Accommodation Jacket | Michael Anderson |

| Assistant Manager for Operation Jacket | James Thompson |

| Assistant Manager for Accommodation Platform | Joseph Garcia |

| Assistant Manager for Operation Platform | Donald Martinez |

| Assistant Manager for Subsea Pipes | Karen Evans |

Project/Program Plan

Millennium stages

Millennium stages refer to a project’s various phases, which are used to organize and plan the project’s activities and tasks (Mnisi, 2020). The project manager and team, led by Melvin Black, have created a project/program plan that includes millennium stages to help organize and plan the construction and installation of the offshore oil rig platform. These stages are designed to break down the project into smaller, manageable tasks, making it easier to track progress, identify issues, and make adjustments as needed. The stages typically include the following:

- Initial planning and design: This stage includes the project’s initial planning, design, and development. It includes finalizing the design of the oil rig platform, creating the project management team, and developing the project teams (Joseph & Timothy, 2021).

- Construction: This stage includes constructing the platform components, such as the jackets, decks, and platforms. It includes operation deck construction, accommodation deck construction, operation jacket construction, and accommodation jacket construction.

- Preparation and transportation: This stage includes preparing and transporting the jackets and platforms (Wilson, 2015). It includes operations platform preparation, operations platform transportation, accommodation platform preparation, accommodation platform transportation, operation jacket preparation, operation jacket transportation, accommodation jacket preparation, and accommodation jacket transportation.

- Installation: This stage includes the installation of the jackets and platforms and installing and preparing the subsea pipes. It includes the installation of the operation jacket, installation of the accommodation jacket, anchoring of the operation and accommodation jackets, installation of the operation platform, installation of the accommodation platform, and testing of the platform systems (Joseph & Timothy, 2021).

- Completion and operation: This stage includes the completion of the project and the transition to the platform’s operation. It includes the final inspection, commissioning, and handover of the platform to the client, as well as the ongoing operation and maintenance of the platform.

Detail activities/tasks:

In addition to the millennium stages, the project plan includes a detailed list of activities and tasks that must be completed to construct and install the offshore oil rig platform successfully. These activities and tasks are broken down into smaller, manageable chunks, then assigned to specific team members or teams. The detailed activities include:

Design and engineering: This includes finalizing the oil rig platform’s design, developing detailed engineering plans and drawings, and coordinating with regulatory authorities to obtain necessary approvals and permits.

Procurement: This includes purchasing materials, equipment, and supplies needed for the construction and installation of the platform.

Construction: This includes the actual construction of the jackets, decks, and platforms, as well as the installation of equipment and systems.

Transportation: This includes preparing and transporting the jackets and platforms to the installation site.

Installation: This includes the installation of the jackets and platforms, as well as the installation of subsea pipes and the testing of the platform systems.

Quality control: This includes implementing quality control measures and inspecting materials, equipment, and work to ensure that they meet the project’s specifications and standards.

Safety: This includes implementing safety measures to ensure that the work is done safely and that the workers are protected from potential hazards.

Project management and coordination: This includes the overall management of the project, including a budget, schedule, and resource management, as well as coordination with the client and other stakeholders.

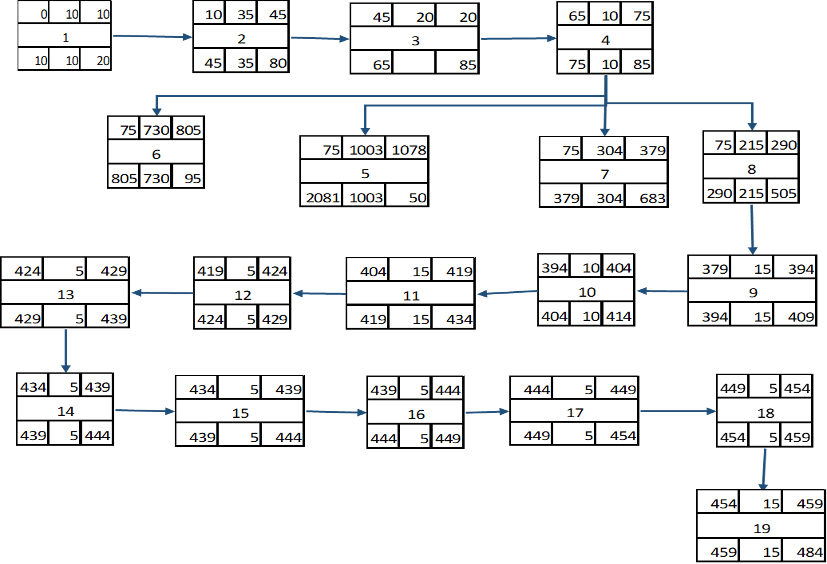

WBS table

A Work Breakdown Structure (WBS) table is a tool to organize and plan the project’s activities and tasks. It breaks down the project into smaller, manageable chunks, which are then assigned to specific team members or teams (Połoński, 2015). The WBS table is a hierarchical representation of the project, starting with the main project goal at the top level and breaking it down into smaller and smaller components as you move down the levels. The WBS table for the offshore oil rig platform project include the main project goal at the top level, followed by the major project phases or milestones, and then the specific activities and tasks that need to be completed to achieve each phase or milestone.

Here is the WBS table for the offshore oil rig platform project:

| Activity | Predecessor | Duration (days) | EST | EFT | LST | LFT | Slack/Float (days) |

| 1 | – | 10 | 0 | 10 | 10 | 20 | 10 |

| 2 | 1 | 35 | 10 | 45 | 45 | 80 | 35 |

| 3 | 2 | 20 | 45 | 65 | 65 | 85 | 20 |

| 4 | 3 | 10 | 65 | 75 | 75 | 85 | 10 |

| 5 | 4 | 1003 | 75 | 1078 | 1078 | 2081 | 1003 |

| 6 | 4 | 730 | 75 | 805 | 805 | 1535 | 730 |

| 7 | 4 | 304 | 75 | 379 | 379 | 683 | 304 |

| 8 | 4 | 215 | 75 | 290 | 290 | 505 | 215 |

| 9 | 7, 8 | 15 | 379 | 394 | 394 | 409 | 15 |

| 10 | 9 | 10 | 394 | 404 | 404 | 414 | 10 |

| 11 | 10 | 15 | 404 | 419 | 419 | 434 | 15 |

| 12 | 11 | 5 | 419 | 424 | 424 | 429 | 5 |

| 13 | 12 | 5 | 424 | 429 | 429 | 434 | 5 |

| 14 | 13 | 5 | 429 | 434 | 434 | 439 | 5 |

| 15 | 14 | 5 | 434 | 439 | 439 | 444 | 5 |

| 16 | 15 | 5 | 439 | 444 | 444 | 449 | 5 |

| 17 | 16 | 5 | 444 | 449 | 449 | 454 | 5 |

| 18 | 17 | 5 | 449 | 454 | 454 | 459 | 5 |

| 19 | 18 | 15 | 454 | 469 | 469 | 484 | 15 |

Critical Path Analysis

Key:

Budget spreadsheet

The budget spreadsheet for the offshore oil rig platform project would include information such as the cost of materials, labor, and equipment for each activity, a breakdown of the costs by category and by stage, and a comparison of the actual costs to the budgeted costs (Phaup, 2018). The budget spreadsheet includes a detailed breakdown of the costs for each subcontractor and any other costs associated with the project, such as travel, accommodation, and other expenses.

| Activity | Description | Budgeted Cost | Actual Cost |

| 1 | Finalized Design Oil rig Platform | £16,500,000 | |

| 2 | Project management team | £1,650,000 | |

| 3 | Creation of project teams | £165,000 | |

| 4 | Documentation and development of manuals and operations documents | £165,000 | |

| 5 | Operation deck construction | £275,000,000 | |

| 6 | Accommodation deck construction | £192,500,000 | |

| 7 | Operation Jacket construction | £44,000,000 | |

| 8 | Accommodation Jacket construction | £38,500,000 | |

| 9 | Operations Platform Preparation | £27,500,000 | |

| 10 | Operations Platform Transportation | £137,500,000 | |

| 11 | Accommodation Platform Preparation | £27,500,000 | |

| 12 | Accommodation Platform Transportation | £137,500,000 | |

| 13 | Operation Jacket Preparation | £16,500,000 | |

| 14 | Operation Jacket Transportation | £82,500,000 | |

| 15 | Accommodation Jacket Preparation | £16,500,000 | |

| 16 | Accommodation Jacket Transportation | £82,500,000 | |

| 17 | Installation of Operation jacket | £165,000,000 | |

| 18 | Installation of Accommodation Jacket | £165,000,000 | |

| 19 | Anchoring Operation and accommodation jackets | £60,750,000 | |

| 20 | Installation of the Operation platform | £82,500,000 | |

| 21 | Installation of Accommodation platform | £82,500,000 | |

| 22 | Installation and preparation of Subsea pipes | £11,000,000 | |

| 24 | Total | £550m | 24 |

Explanation of budget project plan

The budget project plan is a detailed breakdown of the costs associated with the construction and installation of the offshore oil rig platform. It includes information such as the cost of materials, labor, equipment, and other expenses, as well as a breakdown of the costs by category and stage (Gavrilova, 2019). The budget project plan is used to ensure that the project stays within budget and to identify and address any cost overruns. The budget spreadsheet is a key component of the budget project plan. It includes a detailed breakdown of the project’s costs and is updated regularly as the project progresses. The budget spreadsheet allows the project manager and team to track the project’s finances, compare the actual costs to the budgeted costs, and make adjustments as needed.

The budget spreadsheet provided as an example includes 22 activities, with a brief description of each, the budgeted cost, and the actual cost. The costs are in British Pounds, and the total budget for the project is £550,000,000. Each activity is assigned a percentage of the total budget, and it is important to note that the percentages add up to 100%. This means that the project manager and the team have allocated the budget to cover all the activities within the budget. It is important to note that the actual cost may differ from the budgeted cost due to unforeseen events, changes in the project scope, or other factors that may affect the project’s budget (Gavrilova, 2019).

Risks in the project and ways to mitigate them

In this marine construction project context, the project manager, Melvin Black, and his team must consider several key risks. The primary risks include weather conditions in the North Sea, which could significantly impact both the construction and transportation schedules; the availability of cranes and barges, which are essential to the success of the project; and delays in the final design of the oil rig platform, which could also impact both the construction and transportation schedules (Ray, 2021).

To mitigate these risks, the project manager and his team must take several proactive measures. Firstly, they should develop a detailed weather contingency plan for potential weather-related delays or issues (Ray, 2021). This plan should include contingencies for severe weather events and should be regularly updated as the project progresses. Secondly, the project team should book cranes and barges as early as possible to ensure availability and avoid delays. They can also consider other options like hiring the Cranes or Barges from others (Ray, 2021). Furthermore, the project manager and his team must continuously monitor and update the project schedule, taking into account any delays or issues with the final design of the oil rig platform. This will enable them to make adjustments to the project plan as necessary and to minimize the impact of any delays on the overall project completion date. Ultimately, by proactively identifying and mitigating these risks, the project team can increase the likelihood of project success.

Conclusion

In conclusion, the case study analysis of AMEC Marine Construction’s offshore oil and gas production platform project highlights the importance of a thorough project plan and a skilled project management team. The project’s complexity, including the tight budget and timeline, the unique design demands, and the harsh North Sea location, require a well-coordinated effort from the project manager, the team, and all the stakeholders. The project plan outlines the main stages, activities, tasks, and budget, while the project team structure ensures the proper allocation of responsibilities among the team members. Using the critical path method, the AON network diagram, and the forward and backward pass calculations help identify the critical path, project duration, slacks, and floats through the network diagram. All of these elements work together to ensure the successful completion of the project before the winter weather closes in on the area and to avoid the operational lost profit penalty of £300,000 per day.

References

Bargi, K., Hosseini, S. R., Tadayon, M. H., & Sharifian, H. (2011). Seismic Response of a Typical Fixed Jacket-Type Offshore Platform (SPD1) Under Sea Waves. Open Journal of Marine Science, 01(02), 36–42. https://doi.org/10.4236/ojms.2011.12004

Durant, J. (2014, September 21). Customs Ruling. Www.customsmobile.com. https://www.customsmobile.com/rulings/docview?doc_id=HQ%20084959&highlight=9110%2A

Gavrilova, L. (2019). PERSPECTIVE BUDGET PLANNING AS A COMPONENT OF THE BUDGET PROCESS. Investytsiyi: Praktyka Ta Dosvid, 23(3), 65. https://doi.org/10.32702/2306-6814.2019.3.65

Joseph, P., & Timothy, K. (2021, October 14). Initiating and planning stages of project quality management. Www.pmi.org. https://www.pmi.org/learning/library/initiating-planning-stages-project-quality-management-10

Mnisi, P. (2020). The Millennium Projects Management Unit. Www.gov.sz. https://www.gov.sz/index.php/about-us-sp-1053405439/78-economic-planning-a-development/economic-planning-a-development/686-the-millennium-projects-management-unit

Phaup, M. (2018). Budgeting for Mandatory Spending: Prologue to Reform. Public Budgeting & Finance, 39(1), 24–44. https://doi.org/10.1111/pbaf.12210

Połoński, M. (2015). Application Of The Work Breakdown Structure In Determining Cost Buffers In Construction Schedules. Archives of Civil Engineering, 61(1), 147–161. https://doi.org/10.1515/ace-2015-0010

Ray, S. (2021, February 26). The Risk Management Process in Project Management. ProjectManager.com. https://www.projectmanager.com/blog/risk-management-process-steps

Szczęśniak, B. (2018). Spreadsheet as a means to support working time scheduling – data integrity in a spreadsheet tool. Scientific Papers of Silesian University of Technology Organization and Management Series, 2018(135). https://doi.org/10.29119/1641-3466.2019.135.14

Wilson, J. (2015). Paradoxical Utopia: The Millennium Villages Project in Theory and Practice. Journal of Agrarian Change, 17(1), 122–143. https://doi.org/10.1111/joac.12133

Wu, Z., & Li, Y. (2022). Hybrid Model Predictive Control of Floating Offshore Wind Turbines With Artificial Muscle Actuated Mooring Lines. Journal of Dynamic Systems, Measurement, and Control, 144(5). https://doi.org/10.1115/1.4053429

write

write