Abstract

To reduce greenhouse gas emissions, one of the most important and cost-effective strategies is “energy efficiency,” which is defined as using less energy to produce an equal or even greater amount of output. Additionally, good energy efficiency initiatives generally increase a company’s overall efficiency, such as by enhancing production and competitiveness, in addition to the environmental advantages. About 20-25 percent of steel makers’ total expenses come from the energy they use, making iron and steel production their biggest user of it. Reduced production costs have consequently become a major concern of the global steel industry. Companies may save 10-30% of their yearly energy use and save expenses by improving their energy management, according to industry experience. Often, all it takes is a few operational modifications. Several of these energy-saving potentials can be realized in the iron and steel industry within one to two years, and in some cases, within a few months.

Introduction

Energy management systems (EnMS) are beneficial in identifying energy-saving possibilities and reaping long-term advantages. As a result of an EnMS, it is possible to improve and maximize energy efficiency constantly. Ongoing energy conservation efforts by all employees are the most important aspect in achieving long-term success (Beihmanis, 2016). Energy-saving technology can be implemented without the need for large capital expenditures by using an EnMS to monitor current consumption and discover new opportunities. Several additional non-energy efficiency advantages result from a successful EnMS, including increased productivity and quality, reduced liability and asset values, and a reduction in energy usage and costs. Some non-energy-related benefits of increased energy efficiency are worth 2.5 times more than the value of decreased energy demand alone (IEA, 2014b) (Lam, 2017). Depending on current operational practices, an EnMS may be able to produce significant energy savings without the need for expensive capital-intensive technological upgrades. A lack of an energy strategy may lead to a lack of promotion and implementation of chances for energy efficiency improvement. These include senior management commitment, low energy costs, inadequate understanding of the subject, and restricted funds.

Creation of Policy Incentives in This Area

Promoting energy efficiency as a means of reducing greenhouse gas emissions has benefits for both the individual and the public sector. When implementing an energy management system, government initiatives play a critical role in overcoming the more general hurdles (usual lack of knowledge) to adoption (Eccleston, 2011). Many additional obstacles to energy efficiency, such as financial viability and a firm’s perception of technical risk, maybe addressed after an EnMS has been effectively implemented by that company. Energy management systems have been demonstrated to directly correlate with government-led programs that promote and motivate businesses to install them. To put it another way, governments can save a lot of money if these programs are well executed. Resources like training, technical help, and benchmarking tools play a critical part in implementing an EnMS in the workplace (Goldberg, 2011). EnMS deployment may be aided by energy management programs that contain these resources.

In addition, they allow businesses to participate in the program more successfully. Typical government incentives for EnMS adoption include exemptions from carbon or energy taxes, technical assistance, and direct financial incentives like subsidies for audits or special programs (Reinaud, 2011). A tax exemption is disputed, but it is important to keep in mind that incentives for the deployment of an EnMS are supposed to last just a limited time so that enterprises may see for themselves the positive impact that an EnMS can have on their operational efficiency. If a business has matured and understands the benefits of EnMS, further financial incentives are often no longer necessary. For example, if a corporation implements an EnMS, the information generated is used to persuade private investors to participate in energy efficiency initiatives, particularly those more capital-intensive (Horvath, 2012). An EnMS method to documenting energy use, energy savings, and cost reductions should help banks better assess the risks and benefits of these initiatives.

Development of an Energy Management System (EnMS)

Energy management may take many forms, and the financial and reputational importance of each area differs. Suppose you are in the business of managing a big estate of office buildings, for example. In that case, an EnMS is a must-have if you want to provide a defined strategy to energy management to buyers, renters, and joint venture partners (Januard, 2006). The EnMS journey might become needlessly protracted or even misdirected if important energy policy insights and goals are not defined from the beginning. As you begin your journey, this guide may help you get off on the right foot by clarifying policy and strategy from the outset.

As a result, ISO 50001 is not a technical standard. It expects specific technology solutions; each EnMS is unique, and the methods used to assess and optimize energy usage will vary even though many of the techniques employed are similar (Bockel-Macal, 2006). An EnMS may concentrate on process and technology modifications rather than strictly monitoring and evaluating current energy usage to reduce or modify consumption. However, both approaches have their merits. Many EnMS will fall somewhere in between these two extremes. LEED is a built-environment technique that originated in the United States but is now used all around the globe. The Building Research Establishment Environmental Assessment Method (BREEAM) was created in the UK, but is now widely recognized in the United States (BREEAM). Both BREEAM and LEED may be used as stand-alone approaches to an organization’s EnMS, even though they were developed primarily as sustainable design techniques (Jelic, 2010). LEED, for example, may serve as the foundation of an energy strategy, and ISO 50001 can give a risk-based approach to energy assessment.

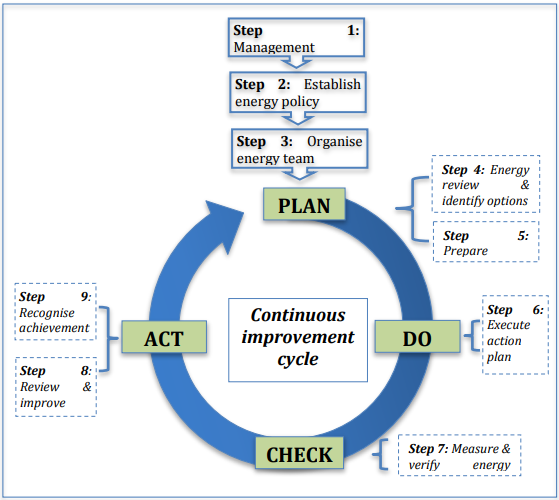

Plan-Do-Check-Act (PDCA) is the foundation of the EnMS process regardless of whether it is modified or adheres to the ISO 50001 standard.

Plan: Conducting an energy evaluation and building a baseline, benchmark against comparable locations, define goals and targets, generate resources and action plans required to achieve outcomes by the organization’s energy policy.

Do: Implement the strategies that have been devised.

Check: Processes should be monitored, measured, and reviewed to ensure that the EnMS and energy policy goals are being met and the EnMS is successful.

Act: As you celebrate your successes and move on with your plans to further enhance energy efficiency and the EnMS, you may create new goals.

- This Plan-Do-Check-Act framework provides a procedure for companies to:

- Establish an energy-savings policy and implement it.

- To satisfy the policy, set goals and objectives to accomplish them.

- Analyze and make choices based on energy usage and consumption statistics;

- Results should be assessed.

- Examine the policy’s efficacy;

Energy management must continually be improved. Implementing an EnMS successfully requires following a certain set of processes within the Plan-Do-Check-Act structure to guarantee continuous improvement. Step 1 of the procedure requires top management support and an accurate energy usage baseline (Step 4). Without senior management’s support, no energy management system can perform successfully, and energy savings are difficult to accomplish and verify without a thorough grasp of the existing energy use on-site.

The ISO 50001 – Energy management systems standard

ISO 50001:2011, a voluntary international standard for energy management systems, was developed by the International Organization for Standardization (ISO) in 2011. (ISO). To satisfy the requirements of an EnMS, ISO 50001 was developed (Lanoie, 2011). Energy management standards and regulations from nations such as China and the United States as well as Europe and Asia may be used to improve energy efficiency in countries like China and Korea. In the public and commercial sectors, organizations of all sizes may use the ISO 50001 management system standard, a traditional one for production and service. Management systems that concentrate on quality and the environment may be used in combination with it, or it can stand on its own (Kahlenborn, 2012). Like ISO 9001 (quality management) and ISO 14001 (environmental management), it follows a Plan-Do-Check-Act framework.

Importance of ISO 50001

There are no fixed goals for increasing energy efficiency in the ISO 50001 standard. Users or regulators should take care of the rest of this. each business may put ISO 50001 into practice in line with its energy strategy and set up a mechanism for continuously improving energy efficiency based on its resources and ability (ISO, 2011). When used as part of a broader energy management strategy, standardized EnMS typically results in cost reductions that would not have been possible with custom solutions. Although these enterprises had previously achieved considerable savings over ten years without utilizing a standardized EnMS, they observed quicker improvement in energy performance when adopting a standardized EnMS and participating in the government’s LIEN program (IEA/IIP, 2012).

Benefits and costs of an EnMS for the iron and steel sector

Iron and steel companies stand to gain a great deal from adopting an EnMS since it is a powerful tool for removing energy efficiency-related informational, institutional, and behavioral hurdles that are still present in the industry (McKane, 2008). EnMS deployment may result in a 10-15 percent reduction in facility-level energy consumption within a short period. In addition, beyond the first implementation phase, energy savings may be maintained and, in certain cases, virtually double the initial savings.

Government programs to support EnMS

It is necessary to encourage the usage of an EnMS via government policy in energy management programs. Such government, energy management programs assist enterprises in overcoming obstacles to installing an EnMS and giving direction and support for the implementation process, which is the key advantage (Scheihing, 2007). An efficient energy management system (EnMS) may help address a number of common challenges to energy efficiency, including financial sustainability and the perception of technical risk. It is possible to think of EnMS as a conduit for knowledge that may help overcome the financial and technical obstacles to energy-efficient project implementation. Programs run by the government, for example, may greatly minimize the difficulties businesses face due to a lack of basic knowledge and technical competence by using simple initiatives and then providing direction to help enterprises uncover potential prospects (Mey, 2011). Companies may also establish their own energy savings goals by using benchmarking tools to compare their energy efficiency and best practices to those of other comparable organizations or locations. The first step to implementing an EnMS is to provide organizations with this information and assistance.

Supporting mechanisms for EnMS implementation

Many practical resources are needed to execute an EnMS such as technical support and best practices sharing, benchmarking tools and case studies. EnMS implementation is hampered by many of these resources, but firms are better equipped to get the most out of the program by incorporating them into energy management programs (Reinaud, 2011).

Companies may compare their processes, operations, and systems to sectoral best-in-class operations at other comparable locations via energy performance or best practice benchmarking. Sharing success stories of iron and steel firms using EnMS to reduce their energy use may serve as a powerful motivator for other industries considering energy efficiency as a viable option (Reinaud, 2012). Energy evaluations and cost-benefit assessments, which take into account the many advantages of energy efficiency measures, may be useful for firms new to EnMS and those looking to enhance their current energy management systems. These tools have been shown to work.

Reducing Energy Consumption and Carbon Footprint

However, not all industries are decarbonizing at the same rate. While the G7 countries (Canada, France, Germany, Italy, Japan, the United Kingdom, and the United States) and the EU have set climate-neutrality goals for 2050, their efforts are now focused on national and regional contexts (Worrel, 2011). We can bring industrial decarbonization to the forefront of global policy discussions by pooling resources. For steel decarbonization investments and innovations to occur, a stable policy environment is required, as the Tracker has shown. After the G7’s most recent energy and climate communiqué, actions are needed to set the foundation for a new industrial policy agenda. The G7 Leaders’ Summit in 2021 is an opportunity for leaders of the world’s most powerful countries to show their full support for this plan.

Conclusion

In the iron and steel industry, energy expenses account for 20-25 percent of total input, therefore cutting down on energy consumption is a priority. The iron and steel sector has shown to reduce energy use while improving production via energy efficiency. An EnMS helps a corporation find the best ways to save energy. EnMS’s systematic continuous improvement technique is one of the most effective strategies to continually enhance energy performance. The iron and steel sector has yet to implement an EnMS, despite the fact that it might save energy and bring other non-energy advantages (up to 2.5 times the value of decreased energy demand). Value-added advantages of energy efficiency and how an EnMS may deliver them cost-effectively are two of the most significant challenges. Each country’s industrial sector has unique needs when it comes to the implementation of EnMS, and these needs must be addressed by government efforts. EnMS adoption is encouraged via energy audits rather than significant capital-intensive technological developments. An EnMS may save companies a significant amount of money in the long run.

References

Beihmanis, K., & Rosa, M. (2016). Energy management system implementation in Latvian municipalities: from theory to practice. Energy Procedia, 95, 66-70.

Lam, J. S. L., Ko, M. J., Sim, J. R., & Tee, Y. (2017, December). Feasibility of implementing energy management system in ports. In 2017 IEEE International Conference on Industrial Engineering and Engineering Management (IEEM) (pp. 1621-1625). IEEE.

Eccleston, C. H., March, F., & Cohen, T. (2011). Inside energy: Developing and managing an ISO 50001 energy management system. CRC Press.

Goldberg, A., Reinaud, J., and Taylor R.P. (2011), Promotion Systems and Incentives for Adoption of Energy Management Systems in Industry – Some International Lessons Learned Relevant for China.

Horvath L. (2012), World Steel Association – Steel Industry & EnMS, Presentation to IIP EnMS Shandong workshop. Retrieved Oct 5, 2014 from http://www.iipnetwork.org/EnMS_WSA_2012.pdf.

Januard, F., Bockel-Macal, S., Vuillermoz, J.C., Leurent, J., and Lebrun, C. (2006) “Dynamic control of fossil fuel injections in EAF through continuous fumes monitoring,” La Revue de Métallurgie-CIT, Juin , pp. 275-280.

Jelic, D.N., Gordic, D.R., Babic, M.J., Koncalovic, D.N., and V.M. Sustersi (2010), Review of existing energy management standards and possibilities for its introduction in Serbia. Thermal Science no. 14 (3):613-623.

Lanoie, P., Laurent-Lucchetti, J., Johnstone, N. and Ambec, S. (2011), Environmental Policy, Innovation and Performance: New Insights on the Porter Hypothesis. Journal of Economics & Management Strategy, 20: 803–842.

Kahlenborn, W. et al. (2012), Energy Management Systems in Practice – ISO 50001: A Guide for Companies and Organisations, Federal Ministry for the Environment, Nature Conservation and Nuclear Safety (BMU).

McKane, A., L. Price, and S. de la Rue du Can (2008), Policies for Promoting Industrial Energy Efficiency in Developing Countries and Transition Economies, for the United Nations Industrial Development Organization, May 2008, Vienna, Austria.

McKane, A., D. Desai, M. Matteini, W. Meffert, R. Williams, and R. Risser (2009), Thinking Globally: How ISO 15001 – Energy Management Can Make Industrial Energy Efficiency Standard Practice, Lawrence Berkeley National Laboratory.

McKane, A., Scheihing, P., and R. Williams (2007), Certifying Industrial Energy Efficiency Performance: Aligning Management, Measurement, and Practice to Create Market Value, Lawrence Berkeley National Laboratory.

Mey, J. (2011), How Can We Facilitate the Introduction of Energy Management Systems (EnMS)?, Paper presented to the ECEEE (European Council for an Energy Efficient Economy) Summer Study, June 2011. Retrieved Oct 10, 2014 from

http://proceedings.eceee.org/visabstrakt.php?event=1&doc=3- 391-11.

Reinaud J. and A. Goldberg (2011), The boardroom perspective: how does energy efficiency policy influence decision making in industry? International Energy Agency and Institute for Industrial Productivity for the IEA Energy efficiency series.

Reinaud, J. and A. Goldberg (2012), Promoting Energy Management Systems through Energy Efficiency Programmes, Incentives and Support – Lessons Learnt from Evaluations in Denmark, Ireland and Sweden.

Worrel, E. (2011), Barriers to energy efficiency: International case studies on successful barrier removal, working paper 14/2011, Development Policy, Statistics and Research Branch, United Nations Industrial Development Organization. Vienna.

Therkelsen, P., Sabouni, R., McKane, A., and Scheihing, P. (2013), Assessing the Costs and Benefits of the Superior Energy Performance Program, 2013 ACEEE Summer.

International Energy Agency (IEA) (2011), 25 Energy Efficiency Policy Recommendations.

International Energy Agency (2013), Tracking Clean Energy Progress 2013 – IEA Input to the Clean Energy Ministerial.

OECD (2013), Improving Energy Efficiency in the Iron and Steel Sector: Opportunities and Financing Challenges [DSTI/SU/SC(2013)18], OECD, Paris, France.

write

write