Modern business strategies must include supply chain management (SCM), which covers the complete process of organizing, sourcing, producing, shipping, and receiving returns for items. SCM is defined as the whole procurement, marketing, and operations management of raw materials into completed goods and services that are subsequently delivered to the final customer (Sharma et al., 2021). It is essential for maintaining effectiveness, economy, and responsiveness to client needs. SCM is undergoing major changes in the Indian business environment as a result of globalization, evolving consumer demands, and technological breakthroughs.

SCM’s origins can be found in the early phases of industrialization when companies realized they needed well-organized procedures to control the movement of goods. SCM is now a multidisciplinary field that includes distribution, logistics, and procurement, among other functions. It has developed over time (Sharma et al., 2021). The development of Supply Chain Management (SCM) in India is intimately linked to the nation’s economic liberalization throughout the 1990s, which facilitated international trade and presented novel prospects and obstacles for enterprises.

Because of the complexity and diversity of the Indian economy, supply chain management (SCM) is extremely important in the country’s economic environment. Considering the large population of 1.4 billion people, making up 17% of the total world population (Worldometers, 2023), diverse geography, and blend of traditional and modern sectors, the implementation of efficient supply chain techniques is essential to maintaining growth. The cost structure, operational agility, and, ultimately, the competitiveness of Indian enterprises in both domestic and international markets are all significantly impacted by the effectiveness of supply chain management (Seifert & Markoff, 2022). Future developments in digitalization, technology, and a move toward sustainable practices will define the scope of supply chain management in India. Businesses are realizing more and more that, in order to remain competitive, they must use creative supply chain solutions as the Indian economy expands. It is anticipated that the incorporation of blockchain, data analytics, and artificial intelligence will completely change the way supply chains function in India (Sharma et al., 2021; Seifert & Markoff, 2022), presenting chances for better risk management, real-time decision-making, and more visibility. This essay offers a thorough examination of supply chain management (SCM), its significance in India, and the implications of future developments for the Indian corporate environment.

Goals of Supply Chain Management in Operations

The objectives of supply chain management (SCM) are closely related to attaining operational efficiency, cutting costs, and improving overall competitiveness in the context of any organization, such as partnerships or one-person companies (OPCs), operating in the dynamic business landscape of India (PackageX, 2022). By streamlining procurement procedures, negotiating advantageous terms with suppliers, and cutting down on manufacturing waste, the company aims to increase cost efficiency. The objective is to promptly adapt to the dynamic demands of the Indian market by prioritizing production flexibility, effective inventory management, and optimized distribution networks, requiring operational agility (Bhatt et al., 2019). Prioritizing client happiness means streamlining order fulfillment procedures, cutting lead times, and raising product standards. Furthermore, the supply chain management plan (SCM) incorporates risk mitigation measures such as supplier diversification, the application of strong risk management techniques, and the utilization of technology to enable real-time supply chain monitoring (PackageX, 2022; Sharma et al., 2021). The company seeks to improve resilience in the face of uncertainties by taking proactive measures to manage potential hazards.

Operations will be significantly impacted by and improved in a number of ways by the pursuit of SCM goals. First, by achieving these goals, the company will be able to improve its forecasting and make more precise predictions on demand trends, market trends, and possible supply chain disruptions. Better decisions and resource allocation will come from this. Second, prioritizing cooperation among team members, suppliers, and distribution partners will strengthen bonds, shorten lead times, and create a more flexible and responsive supply chain (PackageX, 2022). Activities will run more smoothly overall thanks to this cooperative approach. Modern technologies like blockchain, AI, and IoT can be integrated into processes to provide improved traceability, real-time visibility, and process automation (Sharma et al., 2021). The connection will help to raise overall productivity, decrease errors, and improve efficiency.

SCM goals facilitate efficient transactions in the supply chain system. For example, a business that sources raw materials from several parts of India can overcome obstacles by implementing efficient supply chain management strategies that prioritize supplier diversification and risk reduction. In spite of unanticipated occurrences like natural disasters or geopolitical tensions, this makes it possible for a continuous supply chain. The company may also want to cut lead times by using effective distribution facilities, streamlining transportation routes, and putting in place real-time tracking technologies. Order fulfillment goes more quickly as a result, which boosts client happiness and loyalty. SCM objectives should be strategically aligned with the unique demands of the firm in order for it to prosper in the changing marketplace. The fundamental aims and objectives of supply chain management are shown in Figure 1.

Figure 1: Top five goals of supply chain management (PackageX, 2022).

Global Supply Chain Management Strategy

For businesses operating in India, assessing a global supply chain management (SCM) strategy is essential in the constantly growing global marketplace; thus, I will implement a global supply chain. By integrating and coordinating supply chain operations across national borders, a global supply chain management strategy enables businesses to take advantage of global opportunities and overcome obstacles (Sharma et al., 2021). A worldwide approach can find outsized rewards and manage risk through foreign diversification, especially in India, which offers tremendous macroeconomic potential for development and scalability (WISEMAN, 2023). A global supply chain management (SCM) strategy should be taken into consideration for a number of reasons, such as expanding operations across multiple regions to mitigate market-specific risks, strategically sourcing and manufacturing to optimize costs, and accessing diverse markets to tap into new customer bases and diversify revenue streams.

Organizations must take into account the consequences and difficulties of implementing a global supply chain management (SCM) strategy in the Indian market. First, given the variety of Indian cultures and business customs, cultural sensitivity is crucial. It is essential to comprehend regional traditions and business etiquette in order to prevent miscommunication, inefficiencies in operations, and strained relationships with local partners. Second, in order to guarantee compliance, prevent legal issues, and preserve the integrity of the supply chain, one must possess a thorough awareness of local legislation in the complex regulatory environment (Glik, 2023). Third, in order to guarantee dependable logistics, communication, and transportation operations, India’s infrastructure issues must be resolved, particularly in the country’s more isolated or developing areas (Glik, 2023). Finally, communication, data analytics, and real-time tracking all depend on technology integration. To preserve efficiency and visibility, organizations need to make sure that multiple technical systems are seamlessly integrated across different areas (Glik, 2023). It is important to carefully consider these implications and difficulties in order to choose the best SCM approach for success in the ever-changing Indian business environment.

Suppliers and Vendors

In India’s diverse sector, businesses need to pick suppliers and vendors carefully in order to create a dependable supply chain. It necessitates choosing specialized local and foreign primary suppliers. While foreign suppliers have greater resources, global perspectives, and technological advancements, local suppliers are more adaptable and knowledgeable about the Indian market (Amiri et al., 2021). The selection procedure takes into account factors including sustainability, technology, cost competitiveness, and local experience. To forecast market trends and adjust the supply chain to local requirements, laws, and customs, local knowledge is crucial. Competitive pricing boosts productivity without compromising quality. Suppliers’ cutting-edge technology increases the efficiency, traceability, and visibility of the supply chain (Amiri et al., 2021). In response to Indian demand for sustainable products and worldwide trends, suppliers with good sustainability practices are given priority.

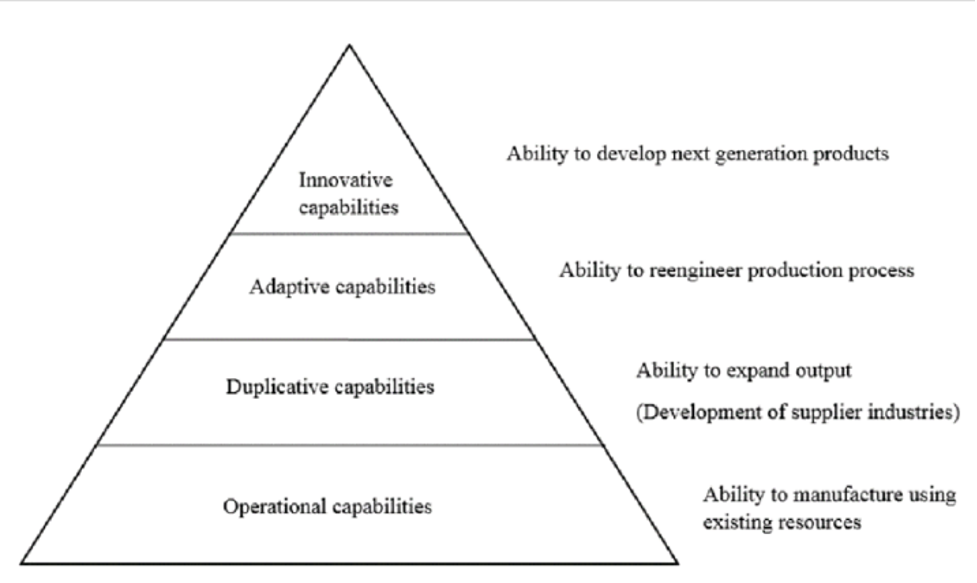

Because of their dependability and consistency in preventing interruptions and ensuring material flow, the organization’s suppliers and partners are crucial to the supply chain and safeguard our operations from unforeseen events. Second, their flexibility enables businesses to adjust production schedules, order volumes, customer preferences, and market trends in response to the dynamic Indian market. The cooperative approach between suppliers and businesses fosters creativity, cost-cutting, and shared prosperity. Strategic goals for quality, cost-effectiveness, sustainability, and innovation are met by the selected vendors that selected. Making strategic choices when choosing vendors and suppliers is crucial for a tactical asset that will increase competitiveness, resilience, and efficiency in the Indian market. The levels of technological proficiency required for supply chain management by a successful Indian automobile firm are depicted in Figure 2.

Figure 2: Levels of technological capacity (Sharmelly & Ray, 2018).

Addressing Shortages in Supply

Business activities may need more skilled workers or equipment in India’s dynamic and unpredictable business climate. During the COVID-19 pandemic, India experienced a shortage of PPE and medical workers, affecting the whole SC system (Bhattacharya et al., 2021). Organizations must use proactive measures to deal with such shortages and keep a strong supply chain. The country dealt with the issue by diversifying sources to lessen reliance on a single source and lessen the impact of disruptions (Bhattacharya et al., 2021). Building cooperative ties with equipment suppliers allows for open communication and the implementation of cooperative strategies, including priority resource allocation or faster deliveries, in times of shortage. With the help of these tactics, organizations can effectively manage the difficulties brought about by shortages and maintain company continuity in the Indian context.

It is also vital to conduct cross-training programs to provide employees with transferable skills and improve workforce flexibility in response to the skilled labor shortage. By working with educational institutions and vocational training programs, talent pipeline development initiatives assist in nurturing a trained pool of professionals, decreasing dependency on the external employment market. During talent shortages, adopting flexible work arrangements like remote work and part-time work allows us to accommodate a wide pool of qualified workers. It increases the resilience of our workforce as a whole.

Having backup plans in place is essential to keeping things running smoothly during shortages. The establishment of rapid response teams with specialized training to manage shortages should be part of a supply chain plan. The teams are capable of making decisions quickly, have predetermined action plans, and use alternate sourcing techniques. Proactive decision-making is made possible by early detection of possible shortages through the use of real-time monitoring and data analytics, as in the Indian case. Working together to identify and evaluate risks, suppliers, and vendors are important stakeholders in collaborative risk management (Bhattacharya et al., 2021). By strengthening agility and flexibility, building solid alliances, integrating technology, and proactively managing the workforce, these initiatives complement the overall supply chain plan.

Acquiring Suppliers or Vendors

When purchasing a vendor or supplier, strategy is essential, particularly in India’s fast-paced economic climate. First, the potential vendor or supplier needs to strategically support our supply chain plan by matching the organization’s long-term vision, beliefs, and ambitions. Second, the geographic presence of the supplier is crucial since it will increase the reach and efficiency of our supply chain in the diverse Indian market if we acquire a supplier with a substantial presence in key locations. To make sure the acquisition aligns with our supply chain efficiency and innovation goals, we assess their technological prowess (Bhatt et al., 2019). Finally, by assessing financial performance and fiscal responsibility, the acquisition should boost our organization’s financial health, making it imperative to assess the possible supplier or vendor’s financial stability.

Acquisitions of suppliers enhance supply chain management, save costs through consolidation, and foster cooperation with the acquired company. The business increases efficiency, responsiveness to the market, and coordination. When companies merge, operational expenses can be reduced, and financial performance can be enhanced through the use of shared resources, economies of scale, and effective procedures. Companies can share information, collaborate to solve problems and achieve shared objectives through acquisition. However, there are challenges (Bhatt et al., 2019). Particularly in highly competitive markets like India, employee and stakeholder opposition to change and regulatory scrutiny necessitates cautious compliance (Bhatt et al., 2019). By solving these challenges, the business can minimize interruptions and benefit from the acquisition of a partner or supplier.

Purchasing a supplier has a big impact on the effectiveness and control of the supply chain. Organizations have better control over production, quality, and timelines when they purchase a supplier, as well as ease of achieving goals (Bhatt et al., 2019). Purchasing a supplier can improve the efficiency of the supply chain by streamlining processes, reducing redundancy, and optimizing resource consumption. To avoid efficiency losses, operations may be momentarily disrupted by the integration process, which calls for cautious management. By adding a supplier, the business can manage risk consistently and have more control over the supply chain. In addition to bringing new ideas, technologies, and techniques, a new supplier can also help the supply chain adjust to shifting market conditions (Bhatt et al., 2019). In India’s fast-paced business climate, Organizations need to be flexible with their supply chain plan, so they have to approach these acquisitions carefully and strategically.

Substantive Recommendations

Sophisticated technologies like AI, IoT, and Blockchain should be prioritized for strategic implementation in order to improve supply chain visibility, traceability, and decision-making. Encourage cooperative relationships with vendors, suppliers, and other important stakeholders to facilitate joint risk management and shared insights for a more robust supply chain network (Bhatt et al., 2019). To solve employee skill shortages and improve workforce flexibility, establish talent development programs through cross-training efforts, educational alliances, and chances for continuous learning. By strategically diversifying suppliers, organizations may reduce the dangers of being dependent on just one, making it easier to navigate possible disruptions and guaranteeing a steady supply chain. In order to meet the increasing need for environmentally friendly practices in the Indian market, incorporate sustainability activities into the supply chain plan (Bhatt et al., 2019). These should include encouraging ethical sourcing, minimizing environmental effects, and working with suppliers who share your commitment to sustainability.

Creating a strong regulatory compliance management system is essential to navigating the complex regulatory environment and addressing potential risks and issues in the future scope of supply chain management in India (Bhatt et al., 2019). To ensure ongoing operations, processes must be updated on a regular basis to conform to changes in rules and laws. Second, in order to handle possible issues like natural disasters, geopolitical conflicts, or unforeseen disruptions, crisis management procedures must be established. To reduce the impact on the supply chain, these protocols should include explicit communication tactics, backup sourcing plans, and contingency measures. A proactive strategy must include ongoing observation and study of industry trends, rivalry, and technology developments (Bhatt et al., 2019). Through foresight, opportunity recognition, and proactive management of the dynamic Indian business landscape, the organization may mitigate potential risks and secure the continued prosperity of supply chain management in India.

Conclusion

Strategic Supply Chain Management (SCM) deployment is fundamental to the success of Indian enterprises. Research highlights the role that supply chain management (SCM) plays in helping to manage the intricacies of the ever-changing Indian market through technology integration, cooperative alliances, talent development, and sustainability initiatives. Beyond procurement and logistics, supply chain management (SCM) promotes economic effectiveness, operational flexibility, and customer happiness. Organizations can prosper by embracing SCM because it fosters a trained workforce, partnerships, and the integration of cutting-edge technologies. With supply chain management (SCM) at the core, organizations can take the lead in sustainability, innovation, and efficiency while maintaining smooth operations and predicting market trends in the rapidly changing Indian business environment.

References

Amiri, M., Hashemi-Tabatabaei, M., Ghahremanloo, M., Keshavarz-Ghorabaee, M., Zavadskas, E. K., & Banaitis, A. (2021). A new fuzzy BWM approach for evaluating and selecting a sustainable supplier in supply chain management. International Journal of Sustainable Development & World Ecology, 28(2), 125-142.

Bhatt, P., Khan, S., Kumar, M., & Singh, S. (2019). Strategic Sourcing in Manufacturing Sector: A Case of an Indian Company. Retrieved from https://ieomsociety.org/pilsen2019/papers/558.pdf

Bhattacharya, S., Hossain, M. M., & Singh, A. (2020). Addressing the shortage of personal protective equipment during the COVID-19 pandemic in India public health perspective. AIMS Public Health, 7(2), 223.

Glik, C. (2023, June). Council Post: Why The Supply Chain Crisis Positioned India For Global Trade Growth. Retrieved November 26, 2023, from Forbes website: https://www.forbes.com/sites/forbesbusinesscouncil/2023/06/05/why-the-supply-chain-crisis-positioned-india-for-global-trade-growth/?sh=14e6261858e3

PackageX. (2022, March). 5 Steps to Improve Supply Chain Visibility in 2023 | PackageX. Retrieved from packagex.io website: https://packagex.io/blog/goals-of-supply-chain-management

Seifert, R. W., & Markoff, R. (2022, August 19). The India supply chain revolution. Retrieved from www.imd.org website: https://www.imd.org/research-knowledge/supply-chain/articles/the-india-supply-chain-revolution/

Sharma, V., Raut, R. D., Mangla, S. K., Narkhede, B. E., Luthra, S., & Gokhale, R. (2021). A systematic literature review to integrate lean, agile, resilient, green, and sustainable paradigms in supply chain management. Business Strategy and the Environment, 30(2), 1191-1212.

Sharmelly, R., & Ray, P. K. (2018, January). Influence of policies in capability evolution and industry structure: Lessons from the Indian automotive industry and implications for other developing countries. Retrieved from researchgate.net website: https://www.researchgate.net/publication/325049945

WISEMAN, M. (2023, August 19). The new face of emerging markets: India brings both promise and complexity for global investors. The Globe and Mail. Retrieved from https://www.theglobeandmail.com/business/commentary/article-the-new-face-of-emerging-markets-india-brings-both-promise-and/#:~:text=After%20recently%20overtaking%20China%20as

Worldometers. (2023). India Population (2023) – Worldometers. Retrieved from Worldometers.info website: https://www.worldometers.info/world-population/india-population/

write

write