Abstract

The goal of this study to better understand existing B2B e-procurement practises by highlighting the parts that have worked and those that have failed in the corporate environment. Those who belong to the Council of Logistics Management and the Institute for Supply Management were asked to complete a survey. The data was analysed using a factor analysis, which was based on 185 valid responses. The outcomes. Because they are still in their infancy, electronic procurement-based market services face a number of hurdles, including user reluctance and integration problems (CIF). A representative sample approach should be used in the future to get generalizable results. E-procurement, a key undertaking, can save companies a significant amount of money. It is possible to use the findings of this study to guide firm implementation efforts at various points in time. This study was carried out in order to address the demand for strong empirical data on this critically important topic. At this stage, the e-procurement marketplace lacks guidance.

Introduction

This study investigates the factors that contribute to the success of e-procurement and the challenges it faces as one of the company’s many possible cost-cutting initiatives. It’s called e-procurement when companies buy goods and services online from suppliers. According to a typical company’s procurement costs, indirect procurement or purchasing non-production commodities like personal computers and non-manufacturing items accounts for 30-60 percent of the overall costs of a company’s operations. Data entry and paperwork error repair, speed optimization, and quality problem resolution are just some of the non-value-adding chores that corporate purchasers regularly waste time on.(Turban et al., 2002) Discovering solutions to cut company costs has become increasingly important in light of certain recent developments. Many factors, including the “US Sarbanes-Oxley Act of 2002”, have contributed to the adoption of supply chain management efficiencies by companies since 2001. However, even though e-procurement programmes have been available for some time, there is still a need to better understand how they are implemented, especially in a web-enabled setting. E-procurement adoption appears to be in its infancy in the business world as a whole. In the 157 companies that were examined, less than half were successful.(Group, 2001) Even though around 80 percent of the participants in this study recognised the need of spending analysis, only about half of the participants had a formal expenditure analysis instrument in place. Some corporations had these tools, but they were only able to analyse half of their expenditures. “A recent McKinsey Company survey” found that spending analysis and demand management were the two areas most resistant to change in their organisations (“i.e. challenging the necessity of purchases”). Eighty-five percent of automotive suppliers surveyed by the “McKinsey Company” expect to increase their procurement tool investments, whether at the same level as they are now or higher. Industry studies found that just 8% to 10% of the world’s largest 5,000 corporations had an electronic procurement platform (Attaran & Attaran, 2002)

Methodology

A questionnaire was utilised to gather data for this investigation. There were two questionnaires, one for each stage of the two-part process, used to collect data on the success factors and obstacles of e-procurement adoption.

Each set began with a preliminary set of elements culled from a comprehensive assessment of the literature. Four e-procurement executives were entrusted with assessing the first draught in order to guarantee that the items were complete, clear, and understandable. This feedback prompted a number of revisions to each list. A successful e-procurement rollout can be achieved by considering the following 12 considerations. Each question had an eight-point Likert scale that may be graded on a one-to-seven scale. We were able to determine the barriers to implementation by analysing 13 factors. Participants were asked to indicate how much they agreed or disagreed with various statements using a seven-point Likert scale.

It was delivered to a random number of people on the Institute for “Supply Management and Council of Logistics Management’s” list who had been picked at random. A total of 7,000 people were chosen at random from the prospective respondents’ list. All of the 225 surveys received were completed. Due to the significant number of missing data, only 185 of the questions could be used. This study’s final sample is referred to as a convenience sample because of the difficulty in collecting data.

Results

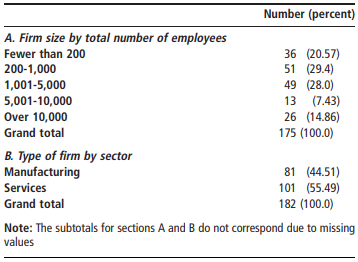

The companies that responded have been categorised in Table 1 One in five businesses has under 1,000 employees, while only one in fifteen has over 10,000 employees. Manufacturing (45 percent) and services (50 percent) account for the majority of the businesses in the sample (55 percent). Table III depicts the success of e-procurement as well as the challenges associated with its implementation. As a result of principle components analysis, the initial factors that explain the most variance in a sample were determined for each set of items (Norusis, 1990)). E-procurement success factors and implementation hurdles were identified by factor analysis of 12 items each. Factor analysis is guaranteed to be accurate with a cases-to-variables ratio of 5:1. To put it another way: The successful results had a 14:1 success-to-barrier ratio, compared to a 13:1 ratio for the “barrier” outcomes. The criterion of “eigenvalue greater than one” (Kaiser, 1974)) calculated the optimal number of components to keep. A three-factor model built from this research explained around 57% of the variance in e-procurement success factors and 54% of the variance in e-procurement implementation difficulties. After the initial components were converted, the initial factors were rearranged using the Varimax rotation method. As long as an item’s factor loading was at least 0.35 in both analyses, it was considered significant.

With values of 0.846 for e-procurement success factors and 0.806 and 0.808 respectively for implementation issues, KMO is also over 0.70. It is therefore projected that each component will be constrained by a sufficient number of elements. Bartlett’s test of sphericity (p 0:000) shows that the variables under each of the e-procurement success and barrier factors are substantially linked, supporting the factor analysis technique. There were approximately 606.795 success factors and approximately 697.540 difficulty factors according to “Bartlett’s sphericity test”. The Bartlett test shows non-zero correlations between both sets of components at a significance level of 0.000, demonstrating the validity of their statistics.

Table 1 Respondent firm descriptive data

Discussion

A three-pronged approach to addressing e-procurement in the organisation is indicated by the findings of this study; the management of suppliers and contracts is the first factor of success. The company’s supplier management needs to be streamlined first. According to this study, e-procurement success is dependent on the number of suppliers a company chooses to deal with being minimised. It makes sense to consolidate suppliers and contracts at the same time in order to save money and get better terms. The best practises for e-procurement truly centralise purchasing rules, standards, technologies, and the actual execution of sourcing to the required departments and personnel in the company. High-volume customers may be better positioned to pool purchasing power when negotiating price reductions with major suppliers, which may make large customer organisations more financially appealing. Focusing on one or two suppliers is a crucial portion of a buyer’s due diligence, and one method to achieve this is by attending “supplier councils” sponsored by companies like Harley-Davidson Motor Company to learn more about the technology plans and future capabilities of their chosen suppliers. (Fitzgerald, 2002) E-procurement projects still face substantial challenges, such as persuading suppliers to fully participate and ensuring that they install the necessary technologies.

Conclusion

Three success criteria and three implementation difficulties were identified for e-procurement from the perspective of the purchasing firm, using data from 12 variables and 13 variables. There are a plethora of questions that need to be answered. Consider things from the suppliers’ perspective to begin with. A larger sample size and a wider range of industries might be employed to evaluate the link between these three success factors and effective procurement performance. There may be significant differences in the e-procurement concerns of large and small organisations or supply chain hub firms and value chain participants if company size is taken into consideration as a control variable. As a further control variable, the type of goods purchased can be used. E-procurement initiatives are most often launched with purchases of non-essential goods and services, according to the findings of this study. When they begin to purchase strategic or direct commodities, they may run across a range of implementation issues. Value chains are only as strong as their weakest link. Identifying any potential impediments to the successful participation of each firm in the chain is crucial. To plan and implement their company’s procurement activities more efficiently, all purchasing executives should be aware of these obstacles to e-procurement implementation. The implementation challenges may change depending on whether the organisation is a hub or a trade partner in the network. Project planners as well as project implementers should be aware of these “pain points” in order to properly plan and implement projects

Reference

Attaran, M., & Attaran, S. (2002). Catch the wave of e-procurement. INDUSTRIAL MANAGEMENT-CHICAGO THEN ATLANTA-, 16–21.

Fitzgerald, K. R. (2002). Best practices in procurement. ASCET—Achieving Supply Chain Excellence through Technology, 4.

Group, A. (2001). Best Practices in e‐Procurement: The Abridged Report. White Paper, December.

Kaiser, H. F. (1974). An index of factorial simplicity. Psychometrika, 39(1), 31–36.

Min, H., & Galle, W. P. (2001). Electronic commerce-based purchasing: a survey on the perceptual differences between large and small organisations. International Journal of Logistics, 4(1), 79–95.

Norusis, M. J. (1990). Statistical package for social sciences. Statistical Data Analysis.

Turban, E., King, D., Lee, J., & Viehland, D. (2002). Electronic commerce: A managerial perspective 2002. Prentice Hall: ISBN 0, 13(975285), 4.

write

write