Abstract

Thermo-preservation is an essential technique for maintaining food quality and safety because it can prevent microbial development and enzymatic activity. The four heat-based procedures will be covered in this article: pasteurization, cleaning, preservation, and blanching. This research examined different thermal processing methods for food preservation, along with temps, processing times, and other essential elements. We compared the benefits and drawbacks of each process, considering how they affected things like appearance, taste, viscosity, and nutritional retention. We discussed the importance of appropriate apparatus upkeep, processing techniques, and paperwork because thermal food preservation raises safety concerns and legal requirements.

To maintain the quality and safety of the food, we found that pasteurization, canning, simmering, and blanching are some of the most effective food preparation techniques. Each method can be used for different kinds of food and has benefits and drawbacks. It is essential to consider legal requirements and safety considerations to guarantee proper administration and compliance with industry standards. This research shed light on the importance of heat retention in preserving the safety and viability of food sources. The study’s results can be applied to improve existing methods of food preservation and create new ones.

1. Introduction

Food must be heated to be preserved thermally because doing so destroys potentially harmful bacteria and enzymes, thereby increasing the food’s storage life and guaranteeing its safety. This research will investigate and assess various thermal food preservation methods, including pasteurization, sanitation, preserving, and blanching. It is impossible to exaggerate the significance of thermal food preservation to the field of food science because it is crucial to maintaining the safety and integrity of the food. Inadequate storage conditions allow dangerous microbes that can lead to foodborne disease to multiply quickly. With the correct use of thermal preparatory methods, this can be avoided.

This research seeks to learn as much as possible about the impacts of thermal processing on food characteristics such as taste, texture, and look, as well as the potential drawbacks of these processes. The importance of appropriate administration, documentation, and upkeep practices will be emphasized. The cooking and storing of food will also be covered in terms of legal and medical issues. This research aims to progress food science by giving a thorough analysis of thermal food preservation techniques. Based on the study’s results, thermal food preservation will become the norm in the food business, protecting the customers’ health and welfare.

2. Methodology

I used the internet to research Thermal Food Preservation. I found information on the websites of the United States Department of Agriculture (USDA), the Food and Drug Administration (FDA), and the Centers for Disease Control and Prevention (CDC). I also found information in books and articles about food preservation. Finally, I talked to a food scientist about thermal food preservation. The USDA website contains pasteurization, sterilization, canning, and blanching information. The FDA website has information on food safety and the regulations governing food production. The CDC website has information on foodborne illnesses and thermal food preservation.

Books about thermal food preservation include Canning: A Guide to Home Preserving, by Betty Crocker; Food Science, Third Edition, by C. N. Purdy and J. I. Fenton; Preservation of Foods by Thermal Processing, edited by Shirley Lassiter et al.; and Canning for a New Generation: A User’s Manual, 2nd Edition, by the National Center for Home Food Preservation. Articles about thermal food preservation include “How to Can Foods,” by Donna Taylor and Beth Chatto; “Canning: A Guide to Home Preserving,” by Betty Crocker et al.; and “Food Science: Principles and Processes,” by C. N. Purdy and J. I. Fenton.

3. Review and Discussion

3.1 Thermal Food Preservation (pasteurization, sterilization, canning, and blanching)

To increase product storage life, prevent food deterioration, and lower the risk of food contamination, the food industry frequently uses thermal food preservation methods like pasteurization, sanitation, canning, and blanching. The different tactics are outlined here in brief:

- Pasteurization: Sterilization can remove bacteria, viruses, and parasites from food. Pasteurization is a common technique for prolonging the shelf life of milk, drinks, and other foods (Sahoo et al.,75). The two most popular sterilization methods are high temperature, short time (HTST), and ultra-high temperature (UHT). (UHT).

- Sterilization: Any residual germs that could cause disease are eliminated during high-temperature sterilization. Foods in cans are pasteurized before being conserved by heating the can to a specific temperature for a set amount of time with the cover on. The best way to preserve food to keep its taste, texture, and nutritious worth for a very long time is to use this technique.

- Canning: Food is preserved through canning and kept in clean, sealed vessels until heated to a high temperature. Food can be preserved in containers using various techniques, including pressure, water bath, and steam canning. The best way to store a meal depends on its ingredients.

- Blanching: it includes quickly immersing food in boiling water to prepare it while preventing food decomposition partly. This process is especially beneficial for fruits and vegetables. Many goods are blanched to maintain their taste and nutritional worth before being preserved or chilled.

Thermal food preservation methods are necessary to keep food as secure, fresh, and edible as possible for an extended period. Depending on the food being preserved and the intended result of the process, the best preservation method must be chosen (Richter Reis 7). The supply of wholesome, safe foods and decreased food waste can all be facilitated by using secure thermal processing methods in the food business.

3.2 Why use modified packaging? The extent of the market

Modified packing for food preservation performs better than traditional heat processing methods like pasteurization, sterilization, preserving, and blanching. Modified packing can slow down food deterioration by changing the receptacle’s environment. It is essential to regulate the container’s dampness, carbon dioxide, and oxygen levels to accomplish this. Using unusual packing methods may have several advantages:

- Fragile products are more secure thanks to improved packing.

- A better quality product is produced when there is less decomposition, which retains more of the food’s taste, texture, and nutritional value.

- The risk of foodborne disease can be decreased using substitute packaging materials that stop the growth of dangerous germs. Foods that spoil quickly can be transported in smaller vessels without losing quality if stored for long periods.

- Agriculture, business, and the food service sectors require hot food preservation. The market is expected to continue growing due to several factors, including advancements in packaging technology, rising customer knowledge of food safety and quality, and increasing demand for quick, on-the-go meals.

There are many benefits to using adapted packing for thermal food preservation, including longer shelf life, better product quality, higher levels of safety, and increased customer satisfaction (Haverkort et al., 45). As more people look for ready-to-eat foods that are both healthy and simple to prepare, the market for thermal food preservation is significant and is expected to grow in the upcoming years.

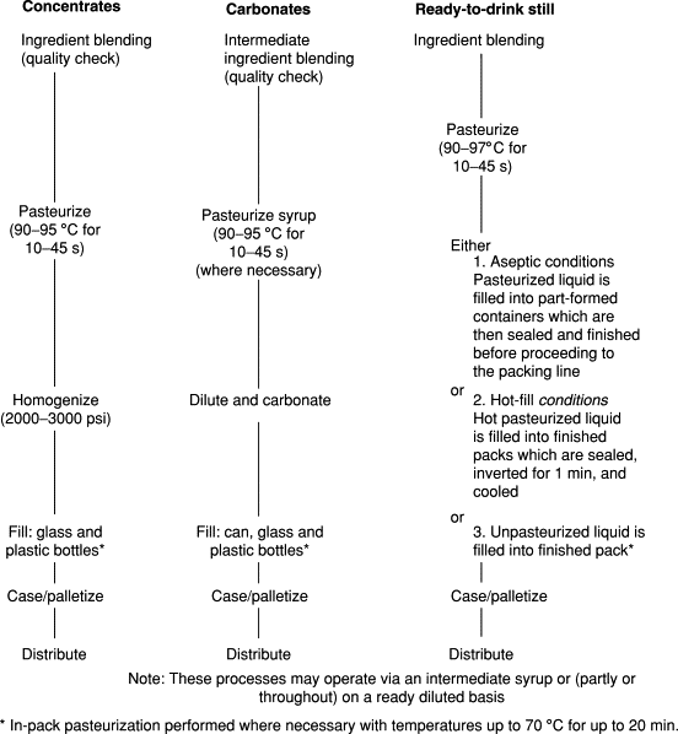

3.3 Processes

Pasteurization, sanitation, preservation, and blanching are among the circumstances and procedures involved in the thermal preservation of food.

Pasteurization:

Liquid or semi-liquid foods, such as milk, drinks, and spices, must be pasteurized. Sacks and shipping vessels ought to be resistant to extreme heat and pressure.

The food object is heated to a specific temperature (typically between 63°C and 100°C) for a specific period to destroy dangerous germs. (typically between 15 and 30 seconds). The substance is quickly cooled to stop further pollution.

Sterilization:

Sterilization is best suited for trustworthy foods and can be kept in airtight receptacles, such as canned products. Metal cans, glass jars, and flexible receptacles are all appropriate choices for high-pressure and high-temperature packing.

The food is heated to a specific temperature for a specific period (typically between 115°C and 130°C) to guarantee that no microbes, including pathogens, remain in the food after packing. (typically between 15 and 90 minutes). After that, the goods are kept in a refrigerated storage building.

Canning:

Proteins, fruits, and veggies must all be packed in oxygen-proof vessels because they are all perishable foods. Metal cans, glass jars, and flexible receptacles are all appropriate choices for high-pressure and high-temperature packing.

The process entails putting the food in a sealed receptacle to preserve it. The receptacle is heated to a specific temperature (typically between 115°C and 130°C) for a set amount of time to kill residual microbes, including spores. (typically between 15 and 90 minutes). After that, the goods are kept in a refrigerated storage building.

Blanching:

Among the items that can be blanched are fruits, veggies, and beans. The packaging components need to be more helpful during this procedure. This technique involves briefly boiling or heating the food to inactivate any enzymes that would otherwise cause it to spoil. (typically between one and five minutes). The object’s rapid cooling stops it from getting any hotter.

Examples of heat-based food preservation methods with strict specifications for the food, receptacle, and packing include pasteurization, sterilization, canning, and blanching. These methods can reduce food wastage, enhance product quality and safety, and lengthen the shelf life of perishable goods.

3.3.1 How can the process (s) be improved

Pasteurization, sanitization, preserving, and blanching are just a few of the thermal food preservation methods that have been around for a while and are still widely used today. The procedures can be improved in several ways to boost effectiveness and quickness. Potential upgrades to heat-based food storage methods include the following:

- The efficiency of the thermal preservation process can be increased by altering its variables, such as temperature, duration, and pressure. This can guarantee that the process effectively removes microbe contamination while only slightly changing the food’s nutritional and taste characteristics.

- One way to increase the efficiency of the thermal retention procedure is to improve packing. For example, using packing materials that can withstand high temps and pressures can lessen the risk of contamination and increase the product’s shelf life.

- The efficiency and success of thermal preservation methods can be improved by using contemporary technologies like high-pressure processing, ultrasonic heating, and microwave heating. These methods might shorten manufacturing periods, stop nutrient loss, and improve the food’s sensory attributes.

- Automation and robotics can increase the reliability and efficiency of the heat retention procedure. Sensors, tracking tools, and automated control systems make sensitive regulation of process factors possible, which reduces human error and improves product quality.

- Integration of other preservation methods: Thermal preservation methods can be integrated with other preservation methods, such as high-pressure processing, irradiation, and natural antimicrobials, to enhance the preservation effect and reduce the impact on the nutritional and sensory qualities of the food product.

Heat-based preservation methods have been around for a while and are still essential for preserving food safety. The effectiveness and utility of these processes will be improved, which will result in food that is safer, of higher quality, and contains more nutrients.

3.4 Advantages and disadvantages

Thermodynamic food preservation techniques like pasteurization, purification, preservation, and blanching each have benefits and drawbacks. Here are a few examples:

The use of heat to preserve food has benefits.

- The storage life of perishable goods can be extended because microbes that lead to degradation during thermal processing are eliminated.

- The probability of sickness caused by contamination is decreased because harmful bacteria, viruses, and parasites are destroyed during thermal processing.

- Refrigeration is not required if cooked foods are kept at ambient temperature.

- Certain thermal processing methods, like blanching, can keep the nutritious worth of veggies by inhibiting the enzymes that cause them to degrade.

- Consumers find certain meals and goods more alluring because preserving and other preparation forms improve their taste.

The following are some drawbacks of using heat for food preservation:

- Sterilization is one type of thermal preparation that can significantly lower nutritional value, especially in vitamin and mineral content.

- It is only sometimes a good thing when thermal cooking changes the structure of food, making it milder or mushier.

- Smaller companies may need help explaining the costly original outlay and continuing operating expenses of thermal processing machinery.

- Enhancement of taste A heat-preparation technique that can change the taste of food, particularly dairy goods, is pasteurization.

- Environmental effects linked to heat generation include high energy usage and the release of greenhouse gases like carbon dioxide.

Heat preservation of food has both benefits and drawbacks. However, they continue to be a crucial element of the food delivery system, especially for protecting perishables and prolonging their shelf life.

3.5 Current/Future trends

Thermal food preservation techniques such as pasteurization, washing, marinating, and blanching have been around for a while, and they are still necessary for keeping food safe for consumption. Several ongoing and impending changes, however, are influencing these strategies. Customers prefer brands that are transparent about their ingredients and avoid using artificial ones. Due to this trend, scientists are developing innovative thermal preservation techniques that utilize natural substances and processes to extend the shelf life of perishable foods. As container technology and materials advance, novel thermal preservation techniques are being developed. To keep food secure from contamination at higher pressures and temperatures, for instance, modern materials with enhanced barrier properties can be used to construct containers.

There is growing concerned regarding the adverse effects of the food manufacturing and packaging industry on the environment. This motivates research into techniques for enhancing heat retention while minimizing resource consumption and loss. In high-pressure manufacturing, microorganisms are destroyed by pressure as opposed to fire. Due to its ability to preserve a more significant proportion of a food’s original flavor and nutritional value, this technique is gaining popularity as an alternative to conventional thermal heating. The entire food industry has been affected by mechanization and technological advancements, including thermal storage methods. The thermal preservation process has improved in speed, uniformity, and quality since the advent of robotics, AI, and the Internet of Things. Thermal food preservation methods continue to be essential, and the market is adapting to altering consumer preferences and emerging trends by developing innovative, cutting-edge techniques. These advancements will likely influence the development of thermal preservation techniques and ensure year-round food availability.

3.6 Environmentally friendly alternatives?

The environmental effect of food preservation can be diminished by switching from heat preservation techniques to more environmentally friendly substitutes. These options include:

- A non-thermal preservation technique known as high-pressure processing, or HPP, employs pressure to eliminate bacteria, viruses, and other microbes. This method can lessen the damaging impacts of thermal processing on the environment while maintaining the food’s nutritional value and taste character.

- Another non-thermal technique for food preservation is irradiation, which uses electromagnetic waves to kill bacteria and other possibly dangerous microorganisms. The purity of food is maintained while chemical preservatives are used as little as possible.

- Natural antimicrobials like organic acids, plant compounds, and essential oils are alternatives to manufactured stabilizers. These organic antimicrobials are safer than artificial stabilizers and can help lessen their damaging effects on the ecosystem.

- Thermal handling can be substituted with vacuum packing to maintain the purity and safety of food. The packing structure can be preserved by denying microorganisms and other pathogens of air, which is what this technique does.

- Another non-thermal technique that has been used for millennia to keep food is fermentation. By turning carbs into organic acids, fermentation prevents the growth of microbes and other pathogens(Pandiselvam et al.,2017). Several ecologically sound alternatives can help lessen the environmental impact of thermal food storage methods without sacrificing the quality or safety of food. Thermal food storage techniques have a significant environmental effect.

3.7 How does the food material

To eliminate dangerous microbes and stop the growth of decaying organisms, food must be pasteurized, which is the process of heating it to a specific temperature for a set amount of time. Pasteurization may change the look, taste, and texture slightly. Fruits and vegetables may soften, and the taste and fragrance of milk may take on a hybrid of caramelization and mellowness.

In order to get rid of any bacteria or other microbes that might have survived pasteurization, sanitation involves heating food to a greater temperature than during pasteurization. Sterilization techniques include high pressure, high temperature, and radiation (Karim et al.,3). The structure, taste, and pigment of dietary ingredients could be significantly changed during sterilization. For instance, vegetables in cans may gradually lose some pigment and become mushier.

The canning technique of food preservation entails prepping food ahead of time, cooking it at a high temperature, and putting it in clean, airtight vessels. Food ingredients’ taste, texture, and structure may be slightly changed through canning. Fruits in a jar generally develop a softer, more delicate texture, while vegetables stored in a container may lose some natural color and texture. To prevent decay and lower the microbial burden, foods are “blanched” and quickly submerged in hot water or vapor (Vaclavik et al.,327). Food is frequently boiled before packing it into containers or storing it elsewhere. After being prepared at a high temperature in water, blanched veggies may become softer and more vibrant.

During pasteurization, a food product is quickly heated to between 60 and 100 degrees Celsius to kill harmful bacteria. A food’s taste, color, and texture can change when it is cooked at a high temperature, but these changes are usually considered small and do not affect the food’s nutritional worth. By subjecting food to temperatures well above 100 degrees Celsius for a prolonged time, sterilization destroys all residual microbes, including spores. This procedure may significantly alter a product’s texture, color, taste, and nutritional worth.

Heating food and placing it in sealed vessels are steps in the canning process. A vacuum barrier created by the thermal process helps to destroy microbes and avoid further contamination. Even though sterilization is typically considered the more damaging thermal processing method, elevated temps can still change the taste and structure of food during canning.

Blanching involves quickly subjecting food to hot water or air to kill enzymes and microbes and weaken them. High heat preparation is usually considered safe and has little effect on the food’s nutritious value, even though it can significantly change its look and structure.

Heat processing can impact food’s texture, color, taste, and overall nutritional worth. Food ingredients may respond differently during thermal food preservation depending on the style and level of preparation.

4. Conclusion

In conclusion, one of the most critical aspects of thermal food preservation is the destruction of microbes and enzymes through heat, which increases the shelf life of food and guarantees its safety. The concepts and methods of thermal food preservation, such as pasteurization, sanitation, preserving, and blanching, will be examined and evaluated in this research. The importance of thermal food preservation in food science cannot be overstated because it is crucial for preserving the safety and purity of food. Inadequate storage conditions allow germs, viruses, and parasites to proliferate, which, if left uncontrolled, can result in foodborne disease. This can be avoided by using the proper heat preparation methods.

References

Haverkort, A.J., Linnemann, A.R., Struik, P.C. and Wiskerke, J.S.C., 2022. On Processing Potato Survey of Products, Processes and Operations in Manufacturing. Potato Research, pp.1-45.

Karim, A., Rehman, A., Lianfu, Z., Noreen, A., Ahmad, S., Usman, M. and Jafari, S.M., 2023. Introduction to thermal food processes by steam and hot water. In the Thermal Processing of Food Products by Steam and Hot Water (pp. 3-26). Woodhead Publishing.

Pandiselvam, R., Subhashini, S., Banuu Priya, E.P., Kothakota, A., Ramesh, S.V. and Shahir, S., 2019 Ozone-based food preservation: A promising green technology for enhanced food safety. Ozone: Science & Engineering, 41(1), pp.17-34.

Richter Reis, F., 2017. Effect of blanching on food physical, chemical, and sensory quality. New perspectives on food blanching, pp.7-48.

Sahoo, M., Titikshya, S., Aradwad, P., Kumar, V. and Naik, S.N., 2022. Blanching, Pasteurization, and Sterilization: Principles and Applications. Thermal Food Engineering Operations, pp.75-115.

Vaclavik, V.A., Christian, E.W., Campbell, T., Vaclavik, V.A., Christian, E.W. and Campbell, T., 2021. Food preservation. Essentials of food science, pp.327-346.

write

write