Introduction

The manufacturing industry stands at a crossroads in today’s world, engaging with pressing sustainability challenges like climate change and plastic pollution. The imperative to innovate sustainably is no longer a choice but a necessity. This report presents a comprehensive sustainability-oriented innovation strategy tailored for a manufacturing organization operating in this sector. The system seeks to identify avenues that mitigate environmental harm and pave the way for a net positive impact. With an increasingly eco-conscious consumer base and tightening regulations, the manufacturing industry must embrace a paradigm shift (Bessant & Tidd, 2014). Integrating sustainable practices into innovation processes can drive competitiveness, enhance brand reputation, and contribute to a greener future. This report demonstrates how this strategy can be actualized, focusing on a specific course of action from idea generation to market commercialization.

However, pursuing sustainability-driven innovation within the manufacturing sector is riddled with intricate challenges. These challenges span three critical dimensions: organizational, commercial, and technological. The organization’s climate stance, leadership style, and existing capabilities significantly influence the feasibility and execution of sustainability-oriented innovations (Hansen & Grosse-Dunker, 2012). Commercially, intellectual property management, identifying the right target market, and a compelling value proposition are pivotal to successful market adoption. Moreover, navigating the technological landscape, striking a balance between new and mature technologies, addressing network externalities, and understanding path dependence further constrain decision-making and implementation (Kalay & Gary, 2015). In the following sections, this report gets into the formulation and implementation of the sustainability-oriented innovation strategy of the manufacturing industry.

Main Body

One concrete approach to implementing the sustainability-oriented innovation strategy in the manufacturing sector is focusing on developing eco-friendly materials for product manufacturing. This course of action aligns with the strategy’s core principles of reducing environmental harm and creating a net positive impact.

Idea Generation

The voyage commences at the inception of ideas within the realm of imagination. Here, diverse teams spanning functions unite to conjure and explore fresh materials characterized by reduced ecological impact. Echoing the wisdom of nature, this approach unfurls avenues for mimicking natural systems to bolster sustainability (Martin-Rios et al., 2020). Insights from the natural world inspire, guiding the quest to unearth materials that emulate its efficiency. Anchored in this ethos, collaborative brainstorming sessions, workshops, and synergistic partnerships with external experts converge to kindle the flames of innovation (Kasemsap, 2017). Through this harmonious symphony of minds, the stage is set for a fertile exchange of ideas, cultivating novel concepts that bear the potential to reshape the course of progress. Thus, the seeds of transformation are sown, promising a tapestry of ingenious possibilities woven from the threads of collective ingenuity.

Research and Development

Upon identifying a promising eco-friendly material, the organization can embark on a dedicated path of Research and Development (R&D) (Ergunova et al., 2017). A steadfast investment in comprehensive exploration characterizes this pivotal stage. Rigorous testing ensues, evaluating the material’s feasibility, robustness, and harmonious integration with established manufacturing procedures. Synergizing efforts with research institutions or universities can expedite this phase, ensuring alignment with stringent industry benchmarks and a steadfast commitment to sustainability objectives. By capitalizing on external expertise, the organization harnesses a collective pool of knowledge to refine the material’s attributes. This collaborative pursuit bolsters the material’s potential for adoption and ensures its seamless transition into real-world applications. As the crucible of innovation, the R&D phase crystallizes the material’s promise, fostering a foundation upon which the edifice of sustainable progress can securely stand (Siqueira & Pitassi, 2016).

Prototyping and Testing

Once a promising eco-friendly material is identified, the next pivotal step is the creation of prototypes for thorough testing and validation. These prototypes undergo meticulous evaluations to ascertain their adherence to stringent quality standards and alignment with sustainability benchmarks. The iterative process involves garnering user insights and subjecting the prototypes to real-world trials (Mead et al., 2020). This comprehensive approach allows for the refinement of prototypes, ensuring they resonate with customers and uphold environmental considerations. This phase is a crucible of innovation, where the tangible embodiment of the eco-friendly material takes shape and is subjected to rigorous scrutiny. Quality assurance protocols are rigorously applied to measure performance and durability, validating the material’s efficacy in real-world scenarios (Goodman, 2013). Concurrently, sustainability metrics are meticulously assessed to confirm that the prototypes align with the intended environmental goals. In summary, the prototyping and testing phase encapsulates the essence of innovation in action. By subjecting eco-friendly material prototypes to robust evaluations, involving users in the process, and refining based on real-world experiences, manufacturing organizations can usher in a new era of sustainable products that harmonize customer needs with environmental consciousness.

Intellectual Property Management

As the innovation journey advances, adept Intellectual Property (IP) management becomes paramount. The organization’s imperative lies in securing patents or trademarks for the novel material and its diverse applications. This safeguarding strategy serves a dual purpose: shielding the invested efforts and preserving a distinctive competitive advantage. In a dynamic landscape where imitation can erode uniqueness, diligently managing IP ensures that the organization maintains its pioneering position (Drejer, 2006). By navigating legal intricacies and proactively securing intellectual property rights, the organization fortifies its innovative foundation, creating a fortified bulwark against potential encroachments. This strategic approach bolsters the long-term viability of eco-friendly innovation, ensuring that the ingenuity behind the new material is perpetually safeguarded and the organization’s distinctive edge remains resilient amidst the currents of change.

Market Commercialization

To capture value, the organization must create a compelling value proposition that resonates with eco-conscious consumers. Marketing efforts should highlight the eco-friendly nature of the material, its benefits for the environment, and the positive impact on customers’ lives (Altenburg & Pegels, 2017). Collaborations with retailers, sustainability certifications, and partnerships with environmental organizations can amplify the market penetration of these products. However, several factors can constrain this course of action. Organizational factors, such as the company’s commitment to sustainability and the willingness to allocate resources, influence the extent of implementation. Commercially, identifying the right target market, effectively communicating the value proposition, and pricing the eco-friendly products competitively are challenges to address. Technologically, striking a balance between innovation and compatibility with existing manufacturing processes and addressing potential network externalities in adoption are crucial considerations. Pursuing eco-friendly material development illustrates the application of the sustainability-oriented innovation strategy (Markides, 1997). By navigating organizational, commercial, and technological constraints, the manufacturing sector can achieve a transformative shift towards sustainability while capturing value in a competitive market landscape.

The organizational, commercial and technological factors

Organizational Factors

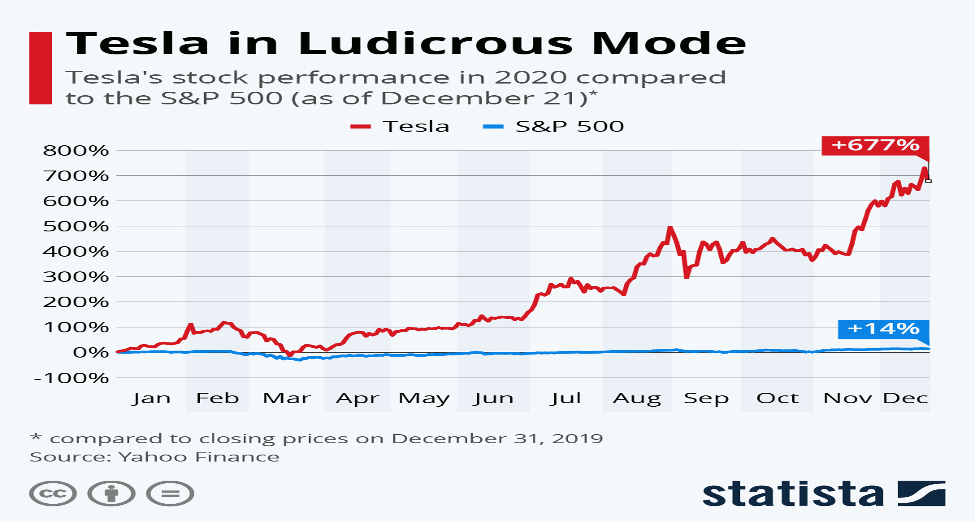

In the field of sustainability-oriented innovation within the manufacturing sector, the organizational context plays a pivotal role. Consider the example of Tesla, a real-world company renowned for its electric vehicles and commitment to sustainable practices. A resolute dedication to environmental responsibility marks Tesla’s internal climate. This climate empowers the company to steer resources toward sustainable innovation, including developing advanced battery technologies and renewable energy solutions. However, this approach may be unique. Some manufacturing organizations might need help embracing such a shift due to entrenched traditional practices or a lack of top-level endorsement. Leadership style also influences the trajectory of sustainability-oriented innovation (Talke et al., 2011). In Tesla’s case, the visionary leadership of Elon Musk propels the company’s endeavours.

Musk’s audacious goals and passion for sustainability motivate the workforce and drive innovation. Contrarily, conservative leadership styles might prioritize short-term financial gains over long-term sustainability investments. This can hinder resource allocation and dampen the enthusiasm required for transformative innovation. Capabilities constitute another organizational factor. Tesla’s cutting-edge technology and research capabilities enable them to create revolutionary products (Sammut‐Bonnici & Paroutis, 2013). However, a manufacturing company lacking expertise in sustainable materials might encounter difficulties researching and developing eco-friendly alternatives. Overcoming this limitation necessitates investment in training and partnerships with academic institutions or research organizations.

Commercial Factors

Turning our attention to the commercial realm, Intellectual Property (IP) management presents a complex challenge. Tesla’s aggressive stance on open-sourcing patents for electric vehicle technology showcases an unconventional approach to IP (Klewitz & Hansen, 2014). While this fosters collaboration and industry growth, it might only be viable for some companies. Others might grapple with protecting proprietary eco-friendly material formulas while navigating legal intricacies. Tesla’s target market comprises environmentally-conscious consumers who value sustainability and cutting-edge technology. However, determining the right target market for eco-friendly products remains challenging for many manufacturing organizations. For instance, if the target market is narrow enough, reducing production might become challenging due to limited demand.

On the other hand, broader markets might necessitate adjustments to pricing and messaging to attract diverse customer segments. Crafting a compelling value proposition is essential. Tesla’s value proposition stems from its ability to merge sustainability with high performance. However, not all companies possess the cachet of the Tesla brand. Communicating the benefits of eco-friendly products effectively, especially when these products might come at a premium, requires innovative marketing strategies.

Technological Factors

Tesla’s embrace of new technology is integral to its success. The company thrives by pushing the boundaries of electric vehicles and energy storage technology. However, for many manufacturing organizations, transitioning to new technology entails risks. The challenge lies in reconciling the need for innovation with maintaining compatibility with existing manufacturing processes (Adams et al., 2016). Adopting an entirely new eco-friendly material might necessitate changes to machinery, potentially leading to disruptions in production and increased costs. Network externalities also shape the innovation landscape. Tesla’s expansive Supercharger network supports electric vehicle adoption.

Nevertheless, there is a dilemma in sectors where multiple companies need to adopt similar innovations to create a network effect. If other manufacturers follow suit in developing and adopting eco-friendly materials, the market might be willing to embrace the change. This reluctance arises from concerns over product compatibility and availability.

Path dependence is another technological constraint. Tesla’s relatively young existence allows it to operate with limited path dependence. In contrast, long-established manufacturing companies might be anchored to existing materials and processes, reluctant to invest in unfamiliar directions. Breaking free from path dependence requires balancing honouring tradition and embracing progress. Organizational, commercial, and technological factors profoundly influence the journey from sustainability-oriented idea generation to market commercialization in manufacturing (Rubio-Andrés & Abril, 2023). These factors are interwoven and dynamic, shaping organizations’ strategies and choices. Drawing inspiration from real-world exemplars like Tesla, we can discern that the commitment to sustainability, visionary leadership, organizational capabilities, IP management, target market identification, value proposition articulation, technological compatibility, network effects, and path dependence considerations collectively shape the path toward innovation. By navigating these constraints, manufacturing companies can leverage sustainability-driven innovation to create a positive environmental impact while capturing value in an ever-evolving marketplace.

Conclusion

In a world beset by sustainability challenges, the imperative for innovation within the manufacturing sector stands as a beacon of hope. As exemplified by companies like Tesla, the successful realization of a sustainability-oriented innovation strategy requires a delicate dance among organizational, commercial, and technological dimensions. The journey begins within the organization itself. The climate of commitment to sustainability, driven by visionary leadership, becomes the bedrock upon which transformative ideas are nurtured (Neutzling et al., 2018). Tesla’s audacity to challenge conventions and open-source patents demonstrates the potential of leadership to reshape the commercial landscape. However, the path has hurdles. Organizational capabilities, the ability to evolve while navigating the constraints of tradition, and reskilling the workforce to embrace eco-friendly innovation are imperatives.

In the commercial realm, the strategic choices are equally profound. Identifying a target market that resonates with the sustainability ethos requires an astute understanding of customer values. Articulating a value proposition that communicates eco-friendly products’ ecological and societal benefits becomes the conduit to market acceptance. When supported by a thoughtful pricing strategy, this narrative has the potential to bridge the chasm between premium offerings and consumer wallets. Technological prowess completes the triumvirate of success. Embracing new technologies while mitigating disruptions to existing processes is a delicate balancing act. The interplay of network effects and path dependence further underscores the intricacies (Inigo et al., 2020). Achieving network effects hinges on industry-wide collaboration, a testament to the collective impact of sustainability-oriented innovation. Navigating path dependence, though challenging, is essential to liberating manufacturing companies from historical shackles and forging new pathways.

As I conclude this exploration, the synthesis of organizational commitment, shrewd commercial acumen, and adept technological navigation is the key to unlocking the transformative potential of sustainability-oriented innovation in the manufacturing sector. The experiences of real-world exemplars like Tesla serve as guideposts, illuminating the path forward.

References

Adams, R., Jeanrenaud, S., Bessant, J., Denyer, D. and Overy, P., 2016. Sustainability‐oriented innovation: A systematic review. International Journal of Management Reviews, 18(2), pp.180-205.

Altenburg, T. and Pegels, A., 2017. Sustainability-oriented innovation systems–managing the green transformation. In Sustainability-oriented Innovation Systems in China and India (pp. 17-34). Routledge.

Bessant, J.R. and Tidd, J., 2014. Strategic innovation management. Wiley.

Drejer, A., (2006). Strategic innovation: A new perspective on strategic management. Handbook of business strategy, 7(1), 143-147.

Ergunova, O.T., Lizunkov, V.G., Malushko, E.Y., Marchuk, V.I. and Ignatenko, A.Y., 2017, February. Forming a system of strategic innovation management at high-tech engineering enterprises. In IOP Conference Series: Materials Science and Engineering (Vol. 177, No. 1, p. 012046). IOP Publishing.

Goodman, M., 2013. Creativity and strategic innovation management: Directions for future value in changing times. Routledge.

Hansen, E.G. and Grosse-Dunker, F., 2012. Sustainability-oriented innovation. Encyclopedia of Corporate Social Responsibility: Heidelberg, Germany.

Inigo, E.A., Ritala, P. and Albareda, L., 2020. Networking for Sustainability: Alliance capabilities and sustainability-oriented innovation. Industrial Marketing Management, 89, pp.550-565.

Kalay, F. and Gary, L.Y.N.N., 2015. The impact of strategic innovation management practices on firm innovation performance. Research Journal of Business and Management, 2(3), pp.412-429.

Kasemsap, K., 2017. Strategic innovation management: An integrative framework and causal model of knowledge management, strategic orientation, organizational innovation, and organizational performance. In Organizational culture and behaviour: Concepts, methodologies, tools, and applications (pp. 86-101). IGI Global.

Klewitz, J. and Hansen, E.G., 2014. Sustainability-oriented innovation of SMEs: a systematic review. Journal of cleaner production, 65, pp.57-75.

Markides, C., 1997. Strategic innovation. Sloan management review, 38(3).

Martin-Rios, C., Hofmann, A. and Mackenzie, N., 2020. Sustainability-oriented innovations in food waste management technology. Sustainability, 13(1), p.210.

Mead, T., Jeanrenaud, S. and Bessant, J., 2020. Factors influencing the application of nature as inspiration for sustainability‐oriented innovation in multinational corporations. Business Strategy and the Environment, 29(8), pp.3162-3173.

Neutzling, D.M., Land, A., Seuring, S. and do Nascimento, L.F.M., 2018. Linking sustainability-oriented innovation to supply chain relationship integration. Journal of Cleaner Production, 172, pp.3448-3458.

Rubio-Andrés, M. and Abril, C., 2023. Sustainability oriented innovation and organizational values: a cluster analysis. The Journal of Technology Transfer, pp.1-18.

Sammut‐Bonnici, T. and Paroutis, S., 2013. Developing a dominant logic of strategic innovation. Management Research Review, 36(10), pp.924-938.

Siqueira, R.P. and Pitassi, C., 2016. Sustainability-oriented innovations: Can mindfulness make a difference? Journal of Cleaner Production, 139, pp.1181-1190.

Talke, K., Salomo, S. and Kock, A., 2011. Top management team diversity and strategic innovation orientation: The relationship and consequences for innovativeness and performance. Journal of product innovation management, 28(6), pp.819-832.

write

write