Introduction

In Singapore, the tourism industry is constantly going popular, especially after the pandemic period. The food service establishment accordingly provides heritage cuisine to satisfy the customers. One of the renowned restaurant toast box chains is not an exception in this regard. This particular report is aimed to discuss all the aspects related to food safety from the perspective of this restaurant. It will discuss the central kitchen and catering options, packaging materials, food packaging technology, and also food preservation techniques.

Findings

1. Central kitchen and catering operation

Central kitchen operation

The central kitchen, also known as the commissary kitchen, is called the internal facility. One of the famous contemporary coffee chains in Singapore, Toast Box Chains, has concentrated on some business activities from the perspective of the central kitchen operation. the administration supplies ingredients or items to each location of this restaurant (toastbox, 2022). Currently, this restaurant is operating approximately 79 toast and coffee cafes in Singapore. In this particular case, the central kitchen manager oversees the meal preparation along with packaging and distributing to each nod in terms of restaurants belonging to the Toast box chain.

Catering operation

(Source: toastbox, 2022)

Toast box chain has its personal catering crew transports that help to supply the food services in a specific location. In addition to that, three different catering operations and services are provided by this restaurant. The name of different catering operations includes-

Corporate catering: This restaurant company has provided food and drink services to corporate and business functions organized in Singapore.

Concession catering: Toast box chain restaurant also provides their services to seasonal competitors, sports events, and also in live concerts (Cuihua, 2014).

Social event category: This specific category includes birthday parties, housewarming parties, grand openings, retirement celebrations, and also baby showers. It provides different appetizers, bartenders, and servers regarding catering packages.

Different segments of the food production process

The food production department of the restaurant, known as the toast box chain, is well-designed. Some methods of the food production process of this specific restaurant are-

- Curing the food

- Slicing and chopping the vegetables

- Grilling and baking

- Emulsification

- Marinating and grinding (Dey, Richter, Ek, Gu, & Ganjyal, 2021).

- Fermentation of food

- Fermentation of beer

- Broiling, boiling, grilling, steaming, frying, and mixing

- The processing of fruit juice (Dey, Richter, Ek, Gu, & Ganjyal, 2021).

- Soft drink gasification

- Reservation of the food packaging through vacuum pack

- Eradication of the outer layer by skinning and feeling

- Fruit juice processing

Storage condition per regulatory requirements

The restaurant toast box chain Singapore always maintains the guidelines issued by the Singapore food agency. That is the reason the restaurant always ensures to preserve and store the food in the chillers, refrigerators, and freezers by setting a safe temperature (Hammond et al., 2015). The temperature of the chiller or refrigerators is maintained at a temperature of below 4 degrees centigrade, while the freezers in this particular restaurant always maintain a temperature of minus 18 degrees centigrade or below.

(Source: Hammond et al., 2015)

2. Food preservation

Value of food preservation

Preserving food at the right temperature and in the right environment always decreases the condition of food waste, environmental footprint, and also landfill waste. It is most important for the company’s toast box chain in order to maintain the proper food preservation techniques so that they can reduce the microorganism growth in food items (Amit, Uddin, Rahman, Islam, & Khan, 2017). Although, the restaurant toast box chain preserves all the food items from human harmful intervention. Moreover, one of the senior managers of this restaurant has stated that the restaurant always provides food and catering services while maintaining quality and standards. They always utilize aluminum foil paper, safe containers, and some other protective materials to stop the emergence of catastrophic pathogenic bacteria.

(Source: Amit, Uddin, Rahman, Islam, & Khan, 2017)

Various methods of food preservation

The food preservation methods are most important to enhance the shelf-life of the food. The restaurant Toast box chain uses various methods for food preservation, which are in the following.

Chilling: In this particular process, the restaurants keep the food items at a slightly high temperature of freezing point. The storage temperature can vary from -1 to 2 degrees Celsius.

Freezing: this process is utilized mostly for meat preservation for a long time. In that case, – 12 to minus 28 degree Celsius is taken into consideration (Sridhar, Ponnuchamy, Kumar, & Kapoor, 2020).

Drying: This process is generally used by the restaurant to reduce the number of microorganisms naturally used in the drying and smoking process.

Perishability of the food

The perishability of the food is a situation where the food items are prone to decay, spoil and even be unsafe when it comes to consumption. Different types of coffee are the signature of the restaurant toast box chain. In this case, this restaurant’s management always maintains the coffee in a secure environment because it generally loses its freshness once it is exposed to the air. They preserve the coffee in an opaque and also in airtight container at room temperature (Jadhav, Annapure, & Deshmukh, 2021). In addition, they also ensure that the coffee beans are preserved in a cool and dark location. They also use the freezer bag to preserve the whole or sliced bread. Apart from that, the restaurant also utilizes the cold storage approach for preserving the meat and seafood.

Ingredients and substances used in food preservation

The restaurant’s toast box chain uses nitrogen for the cold brewing of coffee. It does not use any kind of harmful preservatives for food preservation and maintains the guidelines in this context provided by the food safety department of Singapore. It uses the preservatives like sodium sorbate and sorbic acid to preserve the baked items and cheese (Guzik, Szymkowiak, Kulawik, & Zając, 2022). On the other hand, they use propionic for bread preservation and sodium nitrate for safeguarding seafood and meat products.

(Source: Guzik, Szymkowiak, Kulawik, & Zając, 2022)

3. Food safety management

Safety practices and protocols in accordance with the legislation of food production establishment

This report already mentioned that the restaurant toast box chain maintains all the guidelines and legislation depicted by the Singapore Food Agency (SFA). This restaurant always operates the following guidelines.

- Ensuring the service Associates of restaurants are free from any kinds of symptoms and also disease. They must inform their supervisor in case they feel any illness.

- They also ensure that the service staff wears a clean dress and maintains personal hygiene to prevent food contamination (Erkmen & Bozoglu, 2016).

- The service staff must have to listen to the food serving and handling process

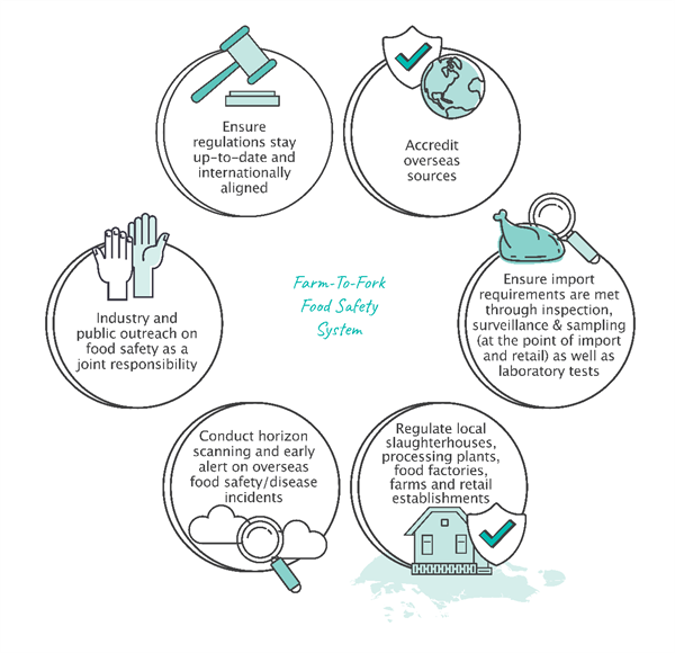

Figure 5: Food safety process in Singapore

Food safety and quality management system

The food safety and quality management system is a great approach for preventing and decreasing foodborne hazards. Some protocols maintained by the toast box chain restaurant employees include-

Firstly, they have obtained their license from the food safety agency. In addition, the hazard analysis and Critical control point (HACCP) have also been implemented in this restaurant in a systematic way for the quality management of food.

The administration has also taken some serious obligations for the food quality management system (Osei Tutu & Anfu, 2019). For example, All the raw materials, ingredients, and processing materials must be safe and free of contamination that would render the finished product unfit for human consumption. Food must be protected from contamination and cross-contamination by storage, processing, and distribution systems that render it unfit for consumption or harmful to health. This incorporates brother control and having cycles and methodology that limit bacterial levels to inside-determined standards. Apart from that, staff training has another consideration area for slicing food waste (Barbancho-Maya & López-Toro, 2022).

Risk assessment and identification of food safety threat

The food safety risk assessment of one of the largest restaurant chains in Singapore, toast box, involves some steps such as hazard recognition, characterization of hazards, exposure evaluation, and risk address.

Identifying the potential hazard is the first step for this company in the risk assessment approach. The risks might include insecure storage solutions and poor ventilation. Thereafter, they identify who is responsible for this particular risk and provide their employees with proper training. On top of that, they also have a culture of great communication and accountability for reducing risk (Attrey, 2017). With the help of effective communication, the restaurant administration always evaluates all risks to gauge employees’ awareness so that the risk does not come in further.

The evolution of bacteria in food products is the main threat to food safety. That is the main reason this restaurant always follows the Sale of Food Act (Food Regulations) for the food regulation and sale of food act (Cap 283) for governing the integrity and quality of the food (Choo, Choy, Ip, Rao, & Huang, 2021). To reduce the exposure of this particular issue, the Toast box chain is also carried out with proper sanitation of surfaces, foods, and all the equipment utilized in making foods.

Problem-solving skills from a safety standpoint

Some problem-solving skills from a safety stand that are mainly followed by toast box chain Singapore are –

- Conflict management skills

- Positive attitude in jobs

- Detailed attention to food processing and serving

- Great teamwork with maintaining collaboration

- Multitasking skills

4. Food packaging technology

Different types of food packaging

The food industry of Singapore has been booming in the past decades, and sustainable food packaging using various technologies is one of the reasons for that.

Some effective food packaging types focused on by toast chain restaurants are –

Cardboard and paper: The restaurant uses these materials because they can be recycled easily.

Aluminum: The aluminum container or aluminum foil is another option that this restaurant has considered for food packaging. The main reason for using foil is to maintain the thermal energy in the foods, which can ultimately conserve moisture, aroma, and flavor (Salgado, Di Giorgio, Musso, & Mauri, 2021).

Biodegradable food packaging: Rice husk and bamboo are other substances utilized by this restaurant due to their biodegradability in nature.

Food innovation

It has been analyzed from the company Toast box chain statement that they have innovated foods mainly belonging to Asian countries. In addition, they have also replicated the foods from Western countries as well. Nanyoung coffee, traditional kaya toast, and chicken curry and rice are this restaurant’s signature. Aside from that, the toast box chain also renders the premix Asian delight paste that is completely ready to cook. Customers can easily use this in their homemade meals (Han, 2014).

Food packaging

The restaurant toast box chain has Incorporated some better food packaging designs for protecting the food from contamination and also protecting them at the right temperature. In addition to that, they have also concentrated more on sustainable packaging so that food can travel from any place without any damage and be discarded. The restaurant has also used the five P techniques in food packaging: promote, present, position, provide, and protect.

Food packaging materials

From the cardboard and biodegradable elements, the toast box chain has highly emphasized the glass jars and the different shapes of glass containers (Drago, Campardelli, Pettinato, & Perego, 2020). Apart from that, this restaurant also uses biodegradable plastic bottles for packaging the beverages. Besides, they have also focused on wood and wax material for food packaging.

Discussion

By analyzing all the information on the regard of food safety of the Toast box chain, it can be said that the restaurant became vociferous regarding food processing and food packaging with the aim of customer satisfaction. The restaurant conducts the annual audit result in order to identify any kind of bleach in preserving and serving the food items. Moreover, it has maintained all the guidelines prescribed by the Singapore food agency. They constantly develop training procedures to transfer knowledge to their employees. It ultimately ensures professional consistency, competence, and commitment.

Conclusion

According to the result of the discussion, it can be stated that the restaurant toast box chain has hosted some efficacious solutions for maintaining food safety and food packaging. In addition to that, they also create various environmental in food rendering such as British colonial styles for promoting a nostalgic ambiance. All the staff and managers associated with this restaurant behave decently with the customers and also meet their requirements.

Recommendation

- Cleaning the surfaces and hands of the serving staff frequently, especially after handling perishable foods like chicken and sea foods

- Avoiding cross-contamination is another recommendation for the restaurant. Separating meat and dairy products from grocery items is necessary in this regard.

- Refrain the refrigeration in the danger zone or between 40 degrees Fahrenheit and 140 degrees Fahrenheit.

References

Amit, S. K., Uddin, Md. M., Rahman, R., Islam, S. M. R., & Khan, M. S. (2017). A review on mechanisms and commercial aspects of food preservation and processing. Agriculture & Food Security, 6(1). https://doi.org/10.1186/s40066-017-0130-8

Attrey, D. P. (2017). Role of risk analysis and risk communication in food safety management. Food Safety in the 21st Century, 53–68. https://doi.org/10.1016/B978-0-12-801773-9.00005-4

Barbancho-Maya, G., & López-Toro, A. A. (2022). Determinants of quality and food safety systems adoption in the agri-food sector. British Food Journal, 124(13), 219–236. https://doi.org/10.1108/bfj-07-2021-0752

Choo, M. Y., Choy, C. P. P., Ip, Y. C. A., Rao, M., & Huang, D. (2021). Diversity and origins of giant guitarfish and wedgefish products in Singapore. Aquatic Conservation: Marine and Freshwater Ecosystems, 31(7), 1636–1649. https://doi.org/10.1002/aqc.3553

Cuihua, Q. (2014). Establish Central Kitchen under HACCP Control in Food and Beverage Industry to Ensure Food Safety and Hygiene. SHS Web of Conferences, 6, 03005. https://doi.org/10.1051/shsconf/20140603005

Dey, D., Richter, J. K., Ek, P., Gu, B.-J., & Ganjyal, G. M. (2021). Utilization of Food Processing By-products in Extrusion Processing: A Review. Frontiers in Sustainable Food Systems, 4. https://doi.org/10.3389/fsufs.2020.603751

Drago, E., Campardelli, R., Pettinato, M., & Perego, P. (2020). Innovations in Smart Packaging Concepts for Food: An Extensive Review. Foods, 9(11), 1628. https://doi.org/10.3390/foods9111628

Erkmen, O., & Bozoglu, T. F. (2016). Food Preservation by Reducing Water Activity. Food Microbiology: Principles into Practice, 44–58. https://doi.org/10.1002/9781119237860.ch30

Guzik, P., Szymkowiak, A., Kulawik, P., & Zając, M. (2022). Consumer Attitudes towards Food Preservation Methods. Foods, 11(9), 1349. https://doi.org/10.3390/foods11091349

Hammond, S. T., Brown, J. H., Burger, J. R., Flanagan, T. P., Fristoe, T. S., Mercado-Silva, N., … Okie, J. G. (2015). Food Spoilage, Storage, and Transport: Implications for a Sustainable Future. BioScience, 65(8), 758–768. https://doi.org/10.1093/biosci/biv081

Han, J. H. (2014, January 1). Chapter 1 – A Review of Food Packaging Technologies and Innovations (J. H. Han, Ed.). Retrieved April 14, 2023, from ScienceDirect website: https://www.sciencedirect.com/science/article/pii/B9780123946010000011

Jadhav, H. B., Annapure, U. S., & Deshmukh, R. R. (2021). Non-thermal Technologies for Food Processing. Frontiers in Nutrition, 8. https://doi.org/10.3389/fnut.2021.657090

Osei Tutu, B., & Anfu, P. O. (2019). Evaluation of the food safety and quality management systems of the cottage food manufacturing industry in Ghana. Food Control, 101, 24–28. https://doi.org/10.1016/j.foodcont.2019.02.028

Salgado, P. R., Di Giorgio, L., Musso, Y. S., & Mauri, A. N. (2021). Recent Developments in Smart Food Packaging Focused on Biobased and Biodegradable Polymers. Frontiers in Sustainable Food Systems, 5. https://doi.org/10.3389/fsufs.2021.630393

Sridhar, A., Ponnuchamy, M., Kumar, P. S., & Kapoor, A. (2020). Food preservation techniques and nanotechnology for increased shelf life of fruits, vegetables, beverages and spices: a review. Environmental Chemistry Letters. https://doi.org/10.1007/s10311-020-01126-2

toastbox. (2022, January 10). Promotions – Toast Box. Retrieved April 14, 2023, from https://toastbox.com.sg/promotions/

write

write