Abstract

This paper aims to investigate how analytics might help enhance supply and demand. Initial steps include defining and explaining supply and demand chain management. An examination of how supply and demand chains could be improved by using descriptive, prescriptive, and predictive analytics is presented in the next section. Demand forecasting, inventory management, transportation, pricing, and supplier interactions are the primary emphasis of this system. The use of analytics to improve supply and demand chains is also discussed in this essay, along with the difficulties and constraints associated with doing so. According to the findings, if analytics are utilized appropriately, they can enhance supply and demand. This essay aims to investigate how analytics might help improve supply and demand. Initial steps include defining and explaining supply and demand chain management. An examination of how supply and demand chains could be improved by using descriptive, prescriptive, and predictive analytics is presented in the next section. Demand forecasting, inventory management, transportation, pricing, and supplier interactions are the primary emphasis of this system. The use of analytics to improve supply and demand chains is also discussed in this essay, along with the difficulties and constraints associated with doing so. According to the findings, if analytics are utilized appropriately, they can enhance speed, reduce costs, and give firms an advantage over their competitors.

Introduction

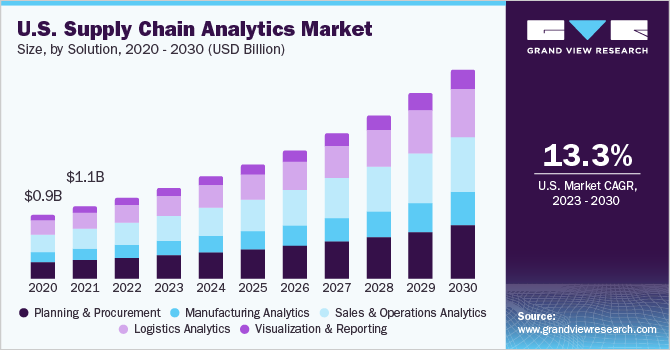

Companies must optimize their supply and demand lines to become more effective, save costs, and provide superior service to their consumers in today’s highly competitive global business environment. The process of controlling the flow of goods, services, information, and money between a firm and its suppliers is referred to as supply chain management of the supply chain. On the other hand, demand chain management requires an understanding of and response to customers’ requirements. The supply and demand chains are being improved through the use of analytics, which includes collecting data, statistical and quantitative analysis, models that explain and predict, and decision-making based on specific facts. Within the scope of this study, we will investigate the most significant ways analytics might enhance supply and demand chains.

Background on Supply Chain Management

Logistics, sourcing, purchasing, and conversion are all supply chain management aspects subject to planning and control. Along with that, it necessitates working together with customers, suppliers, and intermediaries. The goal of supply chain management is to establish a system that can collaboratively function and quickly adjust to shifts in supply and demand. Problems with the supply chain that are frequently encountered include bad connections with suppliers, fluctuating demand and inaccurate projections, inadequate tracking of inventories, inadequate performance in logistics, and a lack of function integration (Katsaliaki et al., 2021). Among the issues that arise are excessive inventory expenses, running out of stock, outdated products, expensive transportation costs, inefficient asset utilization, and failing to meet the requirements of consumers.

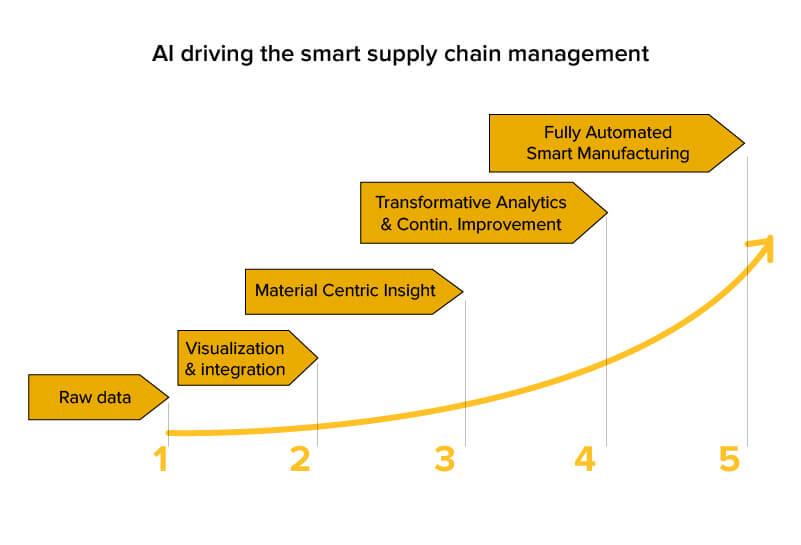

The application of analytics offers fresh viewpoints on the supply chain, allowing for picturing various scenarios and suggesting potential solutions. Tools for analysis that are necessary include predictive modeling, optimization, simulation, and machine learning. With these technologies, businesses can more accurately forecast demand, identify bottlenecks in manufacturing and sourcing, and develop efficient stock management policies, distribution networks, and purchasing strategies.

Background on Demand Chain Management

Customers are effectively served by the demand chain, which identifies and satisfies their requirements. Demand chain management relies heavily on market research, customer relationships, services, and sales (Slam et al., 2023). Finding client groups, keeping track of demand variations, calculating the optimum prices, managing sales channels and campaigns, and ensuring that customers come out ahead are all essential components of effective demand chain management. Suppose you need to manage your demand chain. In that case, you risk having excessive or insufficient inventory, providing lousy customer service, losing market share, and facing lower profit margins.

Similar to supply chain management, analytics has the potential to improve the performance of the demand chain. The identification of customer data trends is one of the ways that analytics assists in determining demand. The customer-friendly characteristics of a product can be discovered through choice modeling and other methods. In addition, analytics allows you to segment customers so that you may tailor your pricing, promotions, and sales channels to specific groups. Customers can be better managed using analytics approaches like churn modeling and lifetime value predictions. An analytics-based demand chain strategy can assist businesses in attracting new consumers, keeping existing ones, and satisfying their needs to achieve profitable growth.

Literature Review

Demand Forecasting

For supply chain planning and execution, many businesses rely on hand-made demand predictions derived from previous sales. Predictive analytics can produce more accurate forecasts using statistical algorithms, machine learning, and historical data (Aljohani, 2023). It is possible to manage massive datasets with several factors using neural networks, exponential smoothing, and ARIMA. Dashboards allow planners to make adjustments to inputs and assumptions while simultaneously viewing the output of the prediction in real time. The demand forecasts, manufacturing schedules, inventory targets, and supplier orders are all utilized by integrated planning systems to generate master supply chain plans.

Inventory Optimization

Choosing inventory for a company’s stocking sites requires considering the costs associated with either an excessive amount or an insufficient amount of stock. The days of supply, fill rates, and stockout occurrences are the metrics utilized in descriptive analytics to evaluate the store’s success. If stocking targets are modified, predictive analytics models the outcome of the adjustment. The most effective policies are determined by prescriptive analytics since they consider service level requirements, cost considerations, and fluctuations in supply and demand (Lee & Mangalaraj, 2022). It is possible to demonstrate just-in-time replenishment and flexible deployment through models. Currently, systems provide stocking points with information regarding when and how much to order.

Transportation Optimization

There are several logistical costs associated with end-to-end supply chain management. Reduced transportation costs for businesses can be achieved by utilizing data-driven network architecture, load optimization, and route planning. By structuring distribution centers and ship-to points, network planning helps to maximize the use of available space and expedite the delivery of services to customers. Load optimization determines how many components to send in each package and in what order (Xin et al., 2022). The final routing optimization process determines the most efficient and economical means of transporting goods along multi-stop routes. Advanced algorithms can analyze a large number of variables and limits in order to reduce the costs of logistics.

Pricing Optimization

Pricing affects the success of supply chain operations because it shifts demand. The use of analytics allows for the optimization of prices by determining the degree to which different client groups and commodities are responsive to changes in price (Raj et al., 2022). Businesses can establish pricing in order to optimize both revenue and profit. With dynamic pricing, prices are continuously adjusted based on factors such as rivals, client demand, and supply levels. Analytics can also make it possible for businesses to implement value-based pricing, which means that they set their prices based on their whole value rather than on their competitors’ costs or prices. In the realm of pricing, analytics serves to replace intuition with data.

Supplier Relationship Management

Activities in the supply chain are dependent on the suppliers. Regarding supplier scorecards, descriptive analytics provide quality, wait time, responsiveness, and total cost information. After that, predictive analytics is used to identify significant source risks, such as difficulties with quality, late delivery, and failure. Using prescriptive analytics, businesses can optimize the selection of suppliers, the negotiation of contracts, the allocation of orders, and the levels of inventory buffers. Analytics helps to ensure supply stability through the improvement of supplier relationships and the reduction of risks.

Demand Sensing and Shaping

Demand chain management relies significantly on data when it comes to understanding customer requirements and purchasing patterns. Businesses can uncover new customer needs and trends through predictive modeling, cluster analysis, and conjoint analysis. With this information, businesses can apply shaping strategies such as product development and marketing to target particular people and products. When discovering latent demand and molding it commercially, analytics are necessary.

Sales Channel Optimization

A corporation’s revenue is increasing due to the increased contribution of stores, distributors, internet sales, and inside sales. Locating the appropriate customers, products, and distribution channels is essential. Businesses can optimize their channel plan with the assistance of analytics by examining each channel’s costs, services, and profitability. Rep sales forecasting, area alignment, and lead scoring are the driving forces behind developing sales force plans. Website optimization, search engine optimization, recommendation engines, and electronic coupons are all examples of digital channel possibilities highlighted by e-commerce analytics (Veglis & Giomelakis, 2019). In omni-channel analytics, customers’ behavior and spending patterns are demonstrated across all platforms.

Customer Relationship Management

Analytics are valuable for improving customer relationship management since they indicate consumer preferences, habits, and revenue potential. With the help of customer lifetime value estimation, churn modeling, and the next-best deal, businesses can keep their most valuable clients. Services can be improved through the use of sentiment analysis of customer feedback. Through attribution modeling, one can ascertain how each offline and online customer interaction influences a customer’s purchase. This results in improved resource utilization as well as client service. Consolidating customer information onto a dashboard for relationship analysis is one of the capabilities of big data analytics. Compare and contrast the two paragraphs.

Implementation strategy

The analytics framework is challenging to use in business, but it does identify essential areas to examine. The following implementation strategy is based on academic research and real-world experience.

Data Integration

The storage of all client data in a data warehouse or lake is the first and most crucial stage in utilizing analytics to improve sales channels and customer interactions. Integration of customer transaction systems, web and mobile activities, customer relationship management (CRM) records, social media, and third-party data is required. Combining these databases results in creating a single source for consumer analytics. This reveals the activity and spending patterns of customers across all platforms.

Organization and Skills

Instead of focusing solely on technology, establish a culture of analytics throughout the entire organization. Data projects need to be promoted by company executives, and their significance should be emphasized. Methods that are driven by data are feasible when sales, marketing, information technology, and analytics work together. Work on improving your skills in internal statistics as well. Make advantage of data scientists who are proficient in the application of predictive models and machine learning. Right now, sales, marketing, and operations employees need to learn how to use analytics tools and evaluate the results of those tools. Technology spending can be maximized with the help of an analytical workforce.

Technology Enablement

Hadoop and visualization tools can perform advanced analytics if the data is high quality and connected. The technological stack must be able to store and analyze large datasets with ease. Data scientists use the platforms to develop algorithms, models, interfaces, and applications for business users. Using self-service access and straightforward interfaces, business teams can analyze the results. Machine learning is utilized by predictive and prescriptive engines in order to report historical trends and make recommendations on future actions.

Change Management

Changes to people and procedures will ensure the utilization of analytics across the entire organization. Depending on the data, it is necessary to rearrange the sales, marketing, and operations departments. Using key performance indicators, managers can monitor the consequences of data. Educate and engage the workers in order to develop their data skills. At the individual and team levels, incentives should be designed to foster fact-based decision-making. Winners of analytics awards are deserving of praise. Analytics and business are brought together through the use of immersive change management.

Execution and Measurement

One must ensure that strategic and tactical plans contain insights from analytical models. As part of the planning process for marketing, product lines, channel resource allocation, and sales, analytics are utilized. In order to gain the benefits of excellent analytics, disciplined performance is all that is required. In order to obtain feedback, monitoring crucial processes and financial data is necessary. The measurement reveals what was successful and what needs to be improved. Sales route management and customer relationship management are both improved by analytics.

Challenges and Limitations of Supply Chain and Demand Chain Analytics

There are numerous challenges to overcome; analytics has tremendous potential. This includes data that is both complex and of low quality, outdated information technology systems that are malfunctioning, a lack of analytical capabilities, shifting supplier networks, cross-functional alignment concerns, return on investment problems, algorithm bias hazards, and more. Significant investments are required in data management, analytics platforms, analytical capabilities, analytics culture, and model governance to solve these problems. We can solve the most significant problems by focusing on data, technology, people, and systems. As per the analytics leaders, it is necessary to address five concerns to maintain a competitive advantage. Organization, talent, information technology systems, data access, governance, and sophisticated analytics approaches are all combined to accomplish this goal.

Conclusion

The global and omnichannel environment that we live in today requires businesses to strengthen their supply and demand lines that are linked together. The ability to successfully navigate these intricate and interconnected flows of commodities, information, and money is essential for the success of businesses. Thanks to analytics, we now have access to new tools that allow us to comprehend, forecast, and establish supply chain and consumer demand targets. The transportation industry, forecasting, stockpile management, and supplier relations could all be revolutionized by descriptive, predictive, and prescriptive analytics. Analytics allows for improvements in price, promotions, sales channel design, consumer research, and customer interactions throughout the demand chain. Despite its shortcomings, analytics can increase sales, save money, lower risk, and maintain customer satisfaction. Businesses that have integrated demand and supply chains and use data will gain a strategic and operational edge over competitors.

References

Aljohani, A. (2023). Predictive Analytics and Machine Learning for Real-Time Supply Chain Risk Mitigation and Agility. Sustainability, 15(20), 15088. mdpi. https://doi.org/10.3390/su152015088

Katsaliaki, K., Galetsi, P., & Kumar, S. (2021). Supply Chain Disruptions and resilience: a Major Review and Future Research Agenda. Annals of Operations Research, 1(1), 965–1002. Springer. https://doi.org/10.1007/s10479-020-03912-1

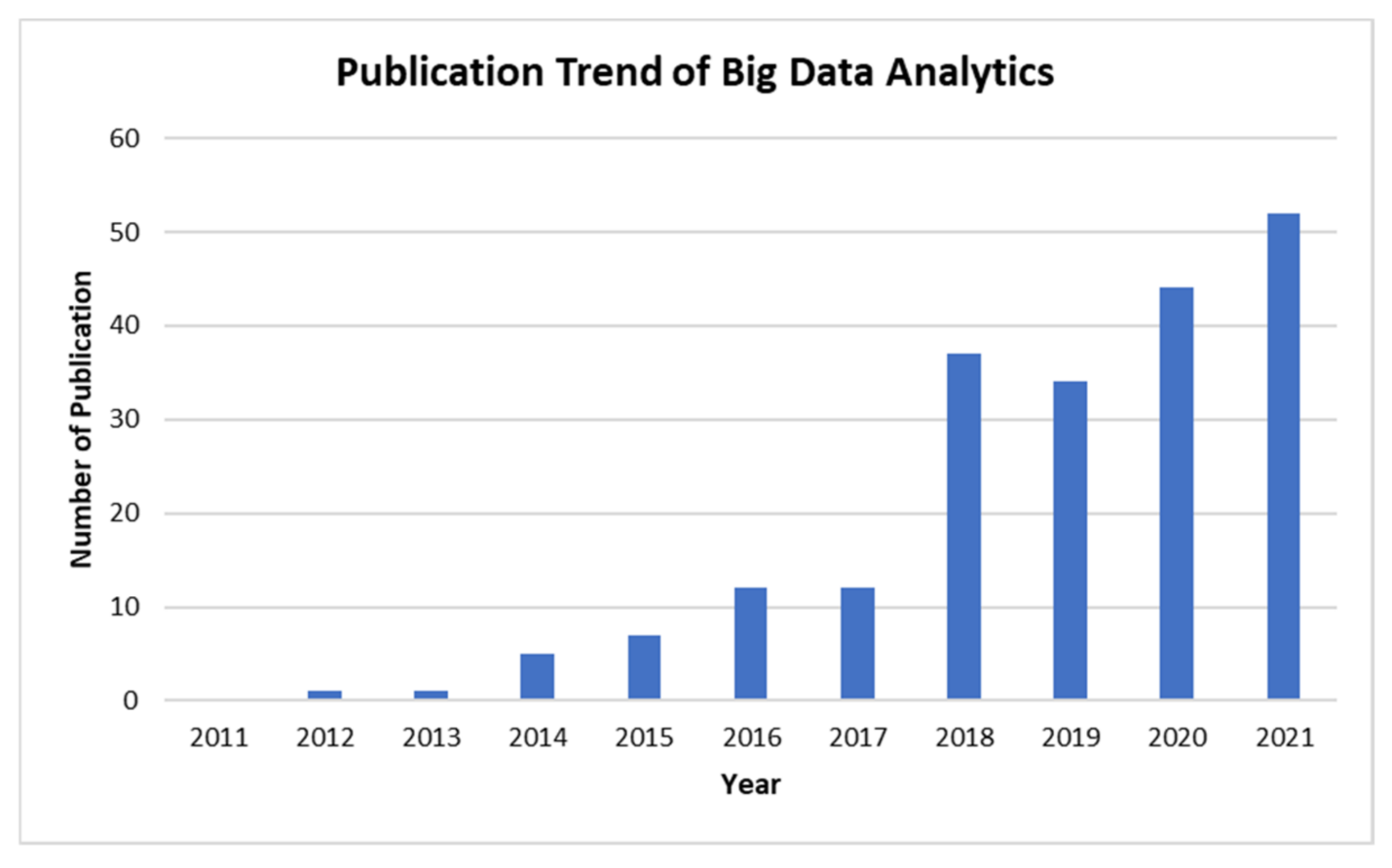

Lee, I., & Mangalaraj, G. (2022). Big Data Analytics in Supply Chain Management: A Systematic Literature Review and Research Directions. Big Data and Cognitive Computing, 6(1), 17. MDPI. https://doi.org/10.3390/bdcc6010017

Raj, A., Mukherjee, A. A., Jabbour, A. B. L. de S., & Srivastava, S. K. (2022). Supply Chain Management during and post-COVID-19 pandemic: Mitigation Strategies and Practical Lessons Learned. Journal of Business Research, 142(1), 1125–1139. NCBI. https://doi.org/10.1016/j.jbusres.2022.01.037

Slam, M. R. I., Monjur, M. E. I., & Akon, T. (2023). Supply Chain Management and Logistics: How Important Interconnection Is for Business Success. Open Journal of Business and Management, 11(5), 2505–2524. https://doi.org/10.4236/ojbm.2023.115139

Veglis, A., & Giomelakis, D. (2019). Search Engine Optimization. Future Internet, 12(1), 6. https://doi.org/10.3390/fi12010006

Xin, L., Xu, P., & Manyi, G. (2022). Logistics Distribution Route Optimization Based on Genetic Algorithm. Computational Intelligence and Neuroscience, 2022, pp. 1–9. https://doi.org/10.1155/2022/8468438

Appendices

write

write