1.0 Executive summary

In a fast-changing world, Systems Thinking and Modeling is an excellent tools for understanding and managing complexity (Bala et al., 2017). It is an interdisciplinary problem-solving strategy incorporating systems theory, modelling, and simulation tools. It provides a comprehensive framework for understanding and managing complex systems, allowing us to investigate the interplay of various system constituents and their associated behaviour throughout time. Systems Thinking and Modeling allow us to identify and evaluate the underlying structures and processes that drive a system’s behaviour and comprehend the impact of changes on the system as a whole. It provides a powerful and valuable tool for decision-makers to investigate the possible outcomes of various interventions, considering the interconnectedness of a system’s components and the long-term implications of their interactions(Sauer et al., 2017). It is a strong tool for understanding and managing complexity, and it may be utilized to build successful strategies and answers to the issues that a fast-changing environment presents. The Ampco Company has been experiencing lower production levels, which have yet to satisfy the consumer’s level of demand. System dynamics, therefore, are used to analyze and solve the problem.

2.0 Introduction

The environment in which automotive components are manufactured is constantly shifting, and businesses such as Ampco need to be able to keep up with the expectations of their customers in order to maintain their position as market leaders. In recent times, Ampco has seen significant growth in the number of orders placed by customers; nevertheless, the company has been unable to modify its production procedures to keep up with the demand. As a direct consequence of this, the company has been dealing with considerable delays in the execution of orders, which has resulted in dissatisfied customers. In this essay, we will investigate how system dynamics can be utilized to solve the growing client demand that Ampco is now facing. System dynamics is an interdisciplinary field that seeks to investigate and explain the behaviour of complex systems over time by combining systems theory, modelling, and simulation approaches (Bala et al., 2017). It gives decision-makers access to a strong tool that allows them to investigate the anticipated outcomes of various interventions and better comprehend and control the numerous risks connected with managing a complex system.

After that, it will investigate the many aspects of system dynamics, such as the variables, feedback loops, and model characteristics. Last but not least, it will talk about the potential benefits of employing system dynamics to solve Ampco’s dilemma and the potential difficulties that could arise from doing so. The environment in which automotive components are manufactured is constantly shifting, and businesses such as Ampco need to be able to keep up with the expectations of their customers in order to maintain their position as market leaders. In recent times, Ampco has seen significant growth in the number of orders placed by customers; nevertheless, the company has been unable to modify its production procedures to keep up with the demand. As a direct consequence of this, the company has been dealing with considerable delays in the execution of orders, which has resulted in dissatisfied customers.

3.0 Problem Analysis and possible solutions

Ampco has seen a significant drop in sales due to several production issues, including insufficient production capacity, a lack of flexibility in production processes, and inefficient resource allocation (Machowiski et al., 2020). The corporation must meet customer demand, resulting in fewer sales and increased customer unhappiness. This issue is made even more difficult because the company needs to promptly make the necessary adjustments to its manufacturing procedures to satisfy the increased demand for its products. Because of this, there have been significant delays in the delivery of orders, which has further undermined the loyalty of customers and led to a decline in sales. In addition to this, the company has seen a decline in efficiency due to its failure to optimize the manufacturing processes and the usage of the available resources. Because of this, costs and profits have gone up (Shire et al., 2018).

In the case of Ampco, system dynamics can be utilized to determine the fundamental structures and processes that are the driving forces behind the company’s manufacturing procedures. It is possible to analyze the dynamics of the system in order to find solutions that will assist the company in better satisfying the needs of its customers. This can be accomplished by considering the system’s many variables, feedback loops, and other characteristics. System dynamics is a method that may be utilized to investigate the potential outcomes of various interventions, such as alterations to the production procedure or the components utilized, and to evaluate the long-term implications that these modifications will have on the system as a whole. The application of system dynamics can also assist in identifying potential areas of risk, such as delays in order fulfilment due to disturbances in supply chain operations. Ampco can design strategies and solutions that can assist it in meeting customers’ demands in a manner that is both more efficient and effective if it first understands the system’s dynamics (Zare et al., 2019).

3.1 Key variables

Applying system dynamics to Ampco’s dilemma requires understanding the numerous variables that determine the system’s behaviour. These variables include customer demand for parts, the company’s production capacity, the resources and labour employed in the manufacturing process, the process’s efficiency, and the supply chain dynamics. Consumer demand is a critical system variable because it dictates how much production capacity is needed to meet demand. The company’s production capacity is also essential since it dictates how quickly parts can be manufactured and how efficiently the process can be run. Materials and labour utilized in the manufacturing process are other essential elements since they influence the cost of production and the quality of the products produced. Another critical aspect is the effectiveness of the manufacturing process, which impacts how rapidly parts can be produced and how cost-effective the process is. Finally, supply chain dynamics are a significant aspect of the system since disturbances in the supply chain can cause order fulfilment delays.

3.2 Solution

The company can therefore use system dynamics and modelling to try and solve the problem. One solution to the issue of insufficient production capacity is to improve the capacity of the production facilities already in operation. This might be accomplished by the purchase of brand-new machinery, the establishment of extra production lines, or the hiring of additional workers. This will assist the organization in meeting the demand of its customers and reducing delays in the execution of orders. Secondly, the company can use system dynamics to improve the production process by implementing various technological equipment that can assist in the production process. Improving production processes can boost the company’s productivity while also cutting expenses. This can be accomplished by automating formerly manual tasks, reducing the waste produced, and optimizing the production process (Shire et al., 2018). Because of this, the company can boost its manufacturing capacity and decrease the time it takes to complete orders.

Moreover, the company can enhance Resource Allocation by increasing its efficiency and cutting costs which are both possible outcomes of improving how resources are allocated within the business. This can be accomplished by implementing more effective scheduling methods, doing away with redundant jobs, and using the available resources better. Consequently, the company can incorporate flexibility into the production process, thus enabling it to adapt more rapidly to shifts in customer demand. This can be accomplished by implementing modular production systems, which provide the business with the capability of rapidly reconfiguring production lines to fulfil shifting customer demands. Integrating production-level feedback loops into the production process enables the business to respond more quickly to customer demand shifts. One way to accomplish this goal is to put in place sensors and automated systems that track client demand and change production levels in response to that data—adopting a Systems Thinking Attitude which assists the business in understanding the interdependencies that exist between the many components of a system as well as the consequences that their interactions have over the long run (Sauer et al., 2017). This can be accomplished by implementing simulation techniques such as System Dynamics, which allow the company to investigate the likely outcomes of various interventions and devise solutions to the problems caused by the interdependencies between the various components of a system.

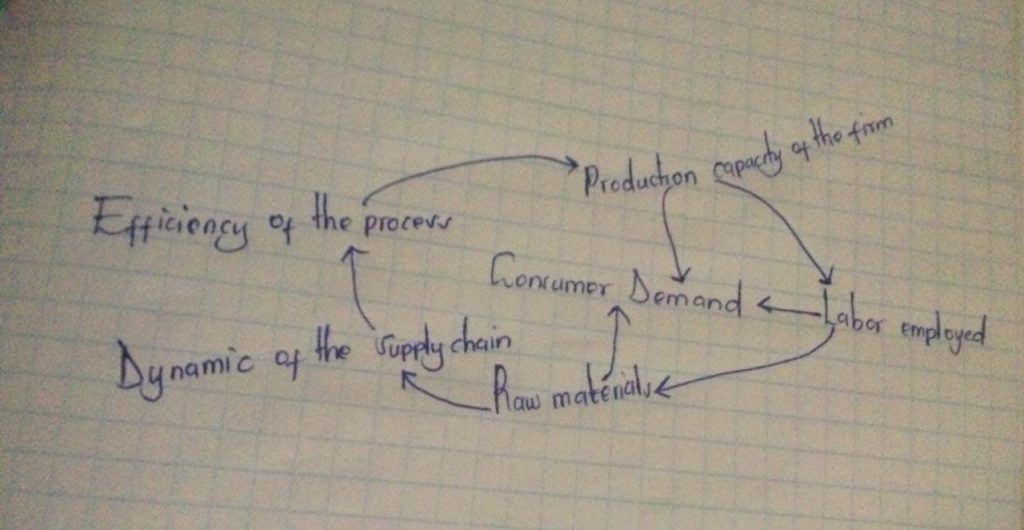

4.0 Loop Diagram

In order to solve the issue with Ampco by employing system dynamics, one must first grasp the components that will go into drawing the loop diagram. These elements include the arrows, which represent the relationships between the components, the feedback loops, which represent the relationships between various elements of the system and their associated behaviour over time; and the nodes, which represent the various components of the system. Each of these elements can be thought of as a representation of a different part of the system. The nodes in the loop diagram are symbolic representations of the many components of the system, such as consumer demand, the firm’s production capacity, the materials and labour employed in the manufacturing process, the efficiency of the process, and the dynamics of the supply chain. The arrows represent the relationships between the components, such as the relationship between customer demand and production capacity or the relationship between the efficiency of the process and the cost of production. Similarly, the arrows may also represent the relationship between the cost of production and the efficiency of the process.

Last but not least, the feedback loops are a representation of the interactions that exist between the various components of the system and the behaviour that is associated with them over time. For instance, a rise in customer demand might cause the firm to raise its production capacity, which in turn can cause an increase in the level of effectiveness achieved by the process. It is feasible to discover solutions that can assist the organization in meeting the demand of customers more successfully if one has a good grasp of the pieces that make up the loop diagram. In order to solve the issue with Ampco by employing system dynamics, one must first grasp the components that will go into drawing the loop diagram. These elements include the arrows, which represent the relationships between the components, the feedback loops, which represent the relationships between various elements of the system and their associated behaviour over time; and the nodes, which represent the various components of the system. Each of these elements can be thought of as a representation of a different component of the system.

The loop diagram clearly shows the relationship between the various variables affecting the Ampco Company. Furthermore, it shows the relationship between the variables and the problem. For example, from the diagram, an arrow shows the relationship between consumer demand and the firm’s production capacity. The relationship between the firm’s production capacity and the labour employed is also shown.

4.1 Limitations of the causal loop diagram

The loop diagram cannot capture all the factors affecting the company leading to failure to meet consumer demands. It cannot also include the complexity of the interactions between the factors or the variables that may lead to incomplete or inaccurate conclusions.

5.0 Summary

System dynamics are applied in several areas and problems related to systems. They are used to direct the process and help in determining the solutions. The Ampco Company, a leading automotive manufacturer, has faced various problems towards consumer demand satisfaction. The problems are brought about by various factors such as the low production capacity of the firm, low flow of raw materials, poor labour, poor efficiency of the production process and the dynamic of the supply chain. The company, therefore, can apply the dynamic system model, for instance, the simple loop diagram, to identify the relationship between the problem and the factors leading to the problem. Once found, these factors/ variables may be utilized to investigate the possible repercussions of system modifications and to propose methods to improve system performance.

System dynamics, for example, may be used to assess the influence of changes in production capacity on system performance. This might assist the organization in identifying viable techniques for increasing production capacity while maintaining efficiency and customer satisfaction. Moreover, system dynamics may be utilized to examine the influence of changes in resource use on system performance. This can assist the organization in identifying viable ways to optimize resource use and lowering expenses.

SYS280 gives students a complete understanding of system practice and business systems. As we start SYS280, we face the intricacy and ask ourselves how to study and remember all this knowledge. One of our team members indicated she recognizes her weaknesses, including learning hurdles, constrained rationality, misinterpretation, and narrow conceptual models. She remembered God’s words: “humans have not been given any wisdom but a little”. Another stated she found the material engaging and learnt a lot about systems and models to address challenges. This training also gives us skills, abilities, and experience to better our comprehension and strategy-making now and in the future. Each business course has given us skills to understand business operations, and this course was no different. The Business Dynamic course gave students several skills to comprehend complex systems. After many hurdles, we began assessing Aramco’s consistency. First, how can we obtain reputable materials quickly and informatively? We spend long days with extensive information and need help to grasp it. We struggled to define the problem with the team. Second, time-consuming that makes compose our analysis that one stated she finds via her investigation, then she figures out this untrue and starts from scratch, with protracted negotiations and team discussions. Finally, one team member reported drawing a causal loop diagram to help the team was a nightmare. Another claimed she had trouble expressing her analysis and loop diagrams after acquiring the appropriate information and sources. The simple loop diagram required the team to create ideas and techniques to be placed in one diagram, each concept following the other, to build and improve the diagram information and outcomes. We had to assess Ampco Company and determine which measures and details to start our diagram information construction.

6.0 Conclusion

To sum up, Ampco has been experiencing difficulties in her production levels, thus leading to customer dissatisfaction. Various factors attracting low production include the poor flow of raw materials, poor human labour and the supply chain dynamic. The company can solve these problems by applying a loop diagram which helps identify the outlying factors, their consequences and the possible solutions.

7.0 References

Bala, B. K., Arshad, F. M., & Noh, K. M. (2017). System dynamics. Modelling and Simulation, p. 274.

Machowski, J., Lubosny, Z., Bialek, J. W., & Bumby, J. R. (2020). Power system dynamics: stability and control. John Wiley & Sons.

Sauer, P. W., Pai, M. A., & Chow, J. H. (2017). Power system dynamics and stability: with synchrophasor measurement and power system toolbox. John Wiley & Sons.

Shire, M. I., Jun, G. T., & Robinson, S. (2018). Applying system dynamics modelling to system safety improvement: Present use and future potential. Safety Science, pp. 106, 104–120.

Zare, F., Elsawah, S., Bagheri, A., Nabavi, E., & Jakeman, A. J. (2019). Improved integrated water resource modelling by combining DPSIR and system dynamics conceptual modelling techniques. Journal of environmental management, pp. 246, 27–41.

write

write