Wild Dog Coffee Company is a small-scale enterprise that deals with various espresso products in a single coffee shop. The company offers those products in a limited breakfast and evening menu but a comprehensive lunch menu. However, the firm intends to add other coffee shop locations to increase sales and profitability of the company. However, Although the company may test new menus in the new site, the management intends to maintain espresso’s same beverage preparation process in the two shops. Regardless, the owner in charge of operations manager purposes to enhance internal customer-facing processes, thus improving the firm’s efficiency. Therefore, the manager prepares a process improvement plan that analyses core processes that need improvement and proposes recommendations on enhancing them. As a result, the company would reach its goals and objectives, thus satisfying its customers and increasing its sales.

Steps of the Preparation Process

The beverage preparation process and the proof of delivering the client’s order involve several steps, which rely on three metrics, customer service, inventory, and quality of the products. Therefore, to enhance the preparation process, the processing manager must identify and improve those metrics. As a result, the whole process will be efficient, and the processing manager will achieve the company’s wishes.

Customer Service

In modern-day businesses, firms have stiff competition, and occasionally they offer equally quality products at friendly prices. For instance, customers will often visit a shop that offers them quality services and treats them well, as opposed to other companies offering substandard treatments. Therefore, customer satisfaction often determines a firm’s success or failure. However, companies that enhance their customer services create a competitive advantage over their competitors (Beukes et al., 2018). As a result, they attract more clients, increase their sales and profitability. Similarly, Wild Dog Coffee could benefit from improving its customers’ service practices and techniques. The procedure does not only start when clients request products, but it should begin with managers laying down strategies on how all clients should be treated. Additionally, the management also formulates strategies that employees should follow thus attain that enhanced customer service. Most clients who visit Wild Dog Coffee companies, including parents and CEOs, always hurry. Therefore, the firm could retain more customers by ensuring faster services without compromising the quality of the products. To improve the metric, the company will track its order delivery time by measuring its time to submit and deliver an order to a client.

Inventory

Managing the inventory is a critical practice in any industry that intends to enhance its supply chain processes. This is because the practice impacts business positively or negatively. For instance, managing inventory involves monitoring and controlling a firm’s products and raw materials, thus ensuring adequate replenishing and serving clients according to their preferences (Priniotakis & Argyropoulos, 2018). A company that does not tract its stock can often realize some vital raw materials are missing, thus fail its customers. In Wild Dog Coffee company, inventory management includes receiving orders, measuring them, and mixing them in the right amounts. If an employee serves a client the wrong quantities in an order, the client may request another correct order, which costs twice, thus increasing production costs. Further, the practice could taint the company’s name, thus causing low sales. Additionally, the firm should also focus on the integrity and accuracy of orders, ensuring that the measurements are uniform all through. For instance, if a client prefers short vanilla in a latte, the firm should provide what the client requires in the right amount regardless of the barista serving the order. To measure the metric, the firm will determine the amount of flavored syrup, espresso beans, and milk before the beginning of each day. Further, the company will compare those amounts against the day’s orders to ensure they suffice. As a result, the firm will maintain an appropriate inventory that does not end momentarily and satisfies all clients.

Quality

Any firm that intends to remain a key competitor in the food industry must strive to offer quality products. The quality of any beverage is related to its raw ingredients’ quality, layout process, and quality of equipment, which ensures customer satisfaction. (Aadil, 2019). Wild Dog Coffee Company is committed to providing that quality, which will ensure clients pay premiums for quality coffee delivery all the time. The firm will deliver coffee at the correct temperatures while maintaining its taste. The company will ensure adequate processing of the milk used in preparing the latte, improving the coffee’s quality. For instance, the employees will stretch the milk effectively, settling at a specific temperature without scorching it or having free air bubbles. The metric manager will identify the metric as stretching milk using a measuring cup and a beeping thermometer to track each order’s temperature.

The Procedure of Preparing Espresso beverage

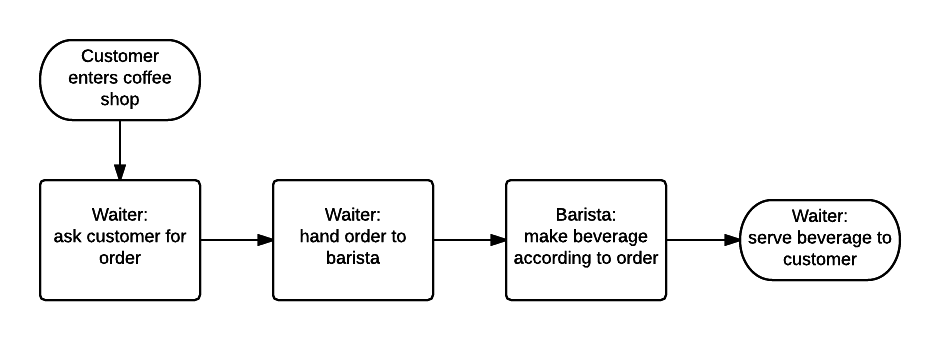

The procedure will detail the making of a flavored latte, providing a template that every barista should follow while serving all the customers. Following the system ensures that the firm improves its customer-facing process and customer satisfaction. The manager plans to achieve that by reviewing the espresso-making process, consistency in each client’s order, and identifying the areas that the firm lacks, thus recommending improvements. Furthermore, improving the procedure will ensure the success of Wild Dog Coffee company and give it a competitive advantage over the other players in the coffee market.

Order Taking

The ordering process begins once a client visits the business premises. The attendant should welcome clients with a big smile to extend a friendly ‘Hello’ or “Welcome to Wild Dog Coffee!” to create the best first impression. Afterward, the employee expects a series of questions from the customer about all menus’ specifications, ingredients, and preparation process. The firms offer an extensive coffee menu, and clients have their tastes and preferences. During that step, the attendant should note the client’s questions and inquire about any dietary restrictions, thus helping the client make informed decisions consistent with their needs. Afterward, the employee should prepare the latter precisely as per the client’s order.

The preparation and specification will involve size, short or tall, temperature, either warm or a mixture with cold, and location, to be taken in the shop or a takeaway. Furthermore, the attendant should also consider the syrup flavor among almond, buttered rum, caramel, cinnamon, hazelnut, Irish crème, orange, peppermint, raspberry, toffee, and vanilla. The attendant should correctly enter the specification in the order-taking system, state its price, receive payment, offer the change, and inform the client to wait in the next window while the drink is under preparation. Once the employee has completed talking the order and entered it into the system, delivery time begins.

Preparing Service Cup

The barista should start preparing the order once entered into the firm’s system and choose the appropriate cup based on the coffee size, temperature, and consumption location. The barista should ascertain if the attendant has recorded the client’s flavor and add it to the coffee in the correct quantity and cup. The barista then should place the cup under the coffee machine, and the next phase starts (Effendy et al., 2019).

Preparing the Espresso

For the barista to start preparing the espresso, they should ensure that the coffee station is free from used coffee grounds. Afterward, the employee should lay the portafilter below the ground coffee machine, then use the lever to dispense the premeasured coffee. The barista should then apply pressure on the grounds to ensure the coffee ground are even and flat in the basked basket. Finally, the employee should attach the portafilter to the machine, press the button for the right size and allow the espresso to fill the cup, then the next phase begins (Aupiais, 2018).

Stretching the Milk

The barista should ensure the steamer line does not have residual water or clogs, thus ascertaining its cleanness. Afterward, the employee should select a milk frothing pitcher to fill it with milk up to the line. After that, the steamer should raise the milk’s temperature to 85 degrees, and then the milk should relax on a pitcher allowing air bubbles to rise to the milk surface. The barista should then allocate solid time on the counter, extracting more bubbles, then swirl the pitcher. Stirring the milk will give it a smooth texture, and once it is reflective, the swirling ends. Therefore, the barista should mix the milk with the prepared espresso cup in a circular motion allowing a seamless mixture (Aupiais, 2018).

Review and Deliver Order

The barista should review the order on the screen to ensure the latter has been prepared efficiently and accurately. After the verification process, the barista should clear the order from the system, end the order delivery time tract, offer the clients their beverages and thank them.

Figure 1: Latte Preparation Flow Chart (Tightops.com. 2020).

Data Analysis for Process Changes

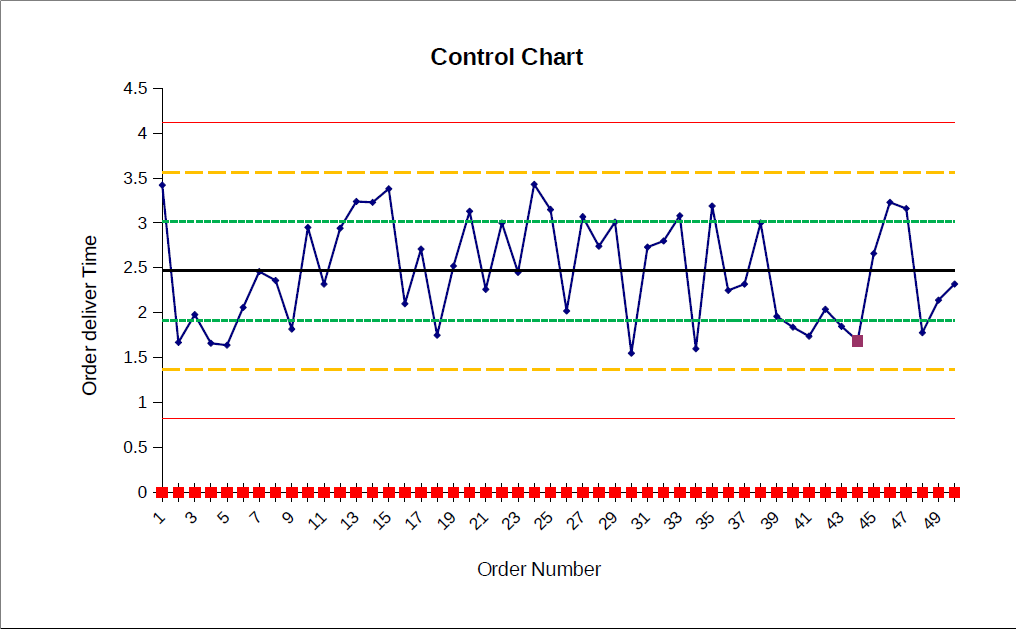

The processing manager plots a control chart detailing order delivery time to determine whether the firm’s process is at its best. The solid black line in the control chart represents the average order time, and it shows that most of the orders take less than 2.5minutes. All the 50 data points showing different order times within the firm are under the two yellow lines placed between 3.5 minutes and 1.5 minutes. Therefore, all orders are centrally placed between the limits without going over or under the threshold limits. All the lines in the chart mark sigma limits connotate various ranges. The green dash shows a range between two and three minutes, the yellow line indicates a range between 1.5 and 3.5 minutes, and another line offers a range between 0.75 and 4 minutes. The processing manager focused on where the 50 data points lay based on the sigma lines, thus determining whether the chart was in control (ASQ, 2019).

The chart does not show any points past the red line, which shows the upper and lower control limits. Additionally, the points do not reach a quorum of two out of three points on the same side of the centerline and further than the yellow line. Further, there are now four out of five points outside the sigma limit, except between points 40-44. The fifth point that goes out of range is colored purple, indicating that the data is slightly out of statistical control.

Figure 2: Control Chart of order delivery time (ASQ, 2019)

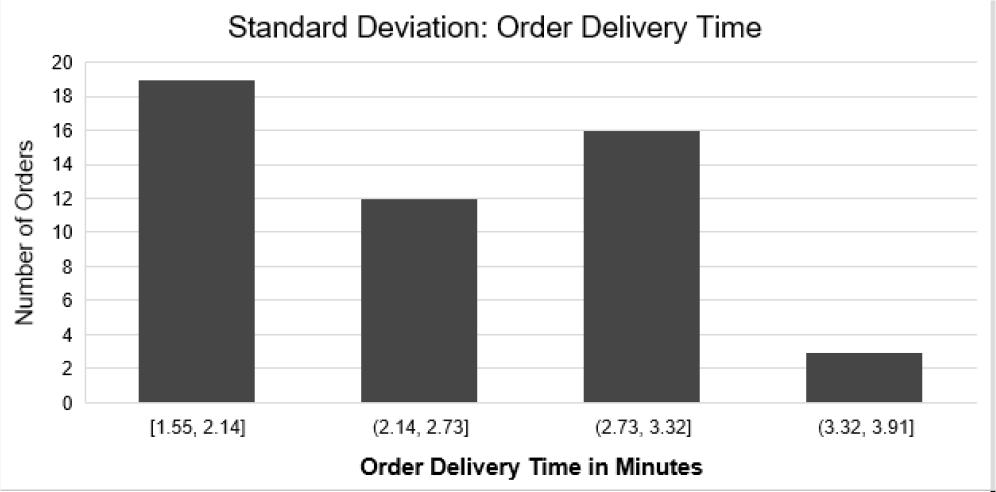

The figure below shows a histogram chart that details the order delivery time, which offers a standard deviation of 0.59 minutes. The chart records the firm’s highest number of orders at 18, served between 1.55 and 2.14 minutes, and three lowest orders served between 3.32 ad 3.91 minutes. The chief barista believes that all orders should take two to three minutes; thus, the employees should improve their service delivery time. However, based on the histogram, the average time for delivering orders is 2.5 minutes which is within the guidelines since the first batch of deviation shows a high population.

Figure 3: Standard deviation histogram of order delivery time

The Cause and Effect of Process Variances

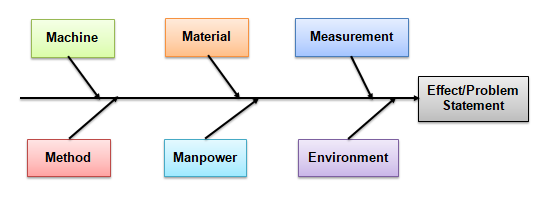

Figure 4: Cause and effect diagram of potential sources of variation in order deliver time (Hessing, n.d)

The Cause-and-effect diagram summarizes the firms’ activities contributing to the process variances. The chart is based on the 6Ms of management, with the Environment representing the firm’s management and how the Ms potentially cause variation to processing and delivering an order.

When an espresso machine breaks down, and there is no employee equipped enough to repair it, or a repair shop within the vicinity, all firm’s operations are crippled until the problem is resolved. Additionally, the coffee machine has a limited number of outputs, which compromises the rate of employees serving customers. Therefore, training employees on repairing coffee machines could save a lot of time during a breakdown. Furthermore, the firm could acquire espresso machines with a larger output to ensure faster services.

The material of equipment and produce used is critical. For instance, espresso beans have varying qualities, and finding the sound quality might be challenging. Further, the milk products should be stored at the proper temperatures to produce quality coffee. Therefore, the company could look for a constant supplier of quality espresso beans to ensure they do not compromise quality or preparation time. Additionally, the company should purchase quality equipment to avoid frequent breakages and enhance the coffee’s quality.

Occasionally, a client may get various measurements of their coffee composition due to different baristas’ services. Additionally, the firm may alter the sizes when transferring coffee components into the machine. Such a practice can impact the quality of coffee. Therefore, the management must ensure that baristas follow the same standard and measurements, thus preventing disparities. Further, the company should retain a standard measure of products from the suppliers, inventory, and use. Such practices could positively impact the business in terms of finances and the quality of the espresso.

The method of preparing an espresso also dramatically determines the efficiency and accuracy of the coffee. Additionally, the format in which the cups are arranged also influences the time of serving espresso. Therefore, preparing a single cup increases the accuracy of mixing coffee ingredients, thus offering clients the exact orders as per their requests. Further, using an assembly line could increase the rate of preparing orders, thus saving time.

Any company that plans to succeed in its undertakings should have the appropriate human resources. For instance, having a low number of employees could derail the business if an employee is sick or has an emergency. Further, unqualified employees and leaders could compromise the company’s operations and, consequently, its success. Therefore, training employees on how to handle clients effectively and ensure order accuracy would improve business operations. Further, all leaders should manage their subordinates appropriately and encourage them on the importance of excelling in their duties.

The management also plays a crucial role in passing and implementing appropriate business strategies that benefit the firm. Therefore, critiquing the educational history of company leaders ensure they are up to the task and are qualified to run company operations. Further, a management team that conducts itself appropriately gains respect from the other staff members, which saves time and improves processes within the firm.

Recommendations

After a critical analysis of the firm’s operations and production processes, the processing manager formulated several recommendations to use and enhance its operations. Most of the suggestions revolve around helping employees and baristas perfect their work through processing all client’s orders reliably and effectively.

Customer Service

A critical factor that the firms should follow to improve customer service is enhancing order delivery time. To affect the initiative, attendants should communicate clearly to all clients while receiving their orders. Therefore, the company should train its employees effectively, allowing them to answer the clients precisely and clarify the menus. Such practices will ensure the barista gets clear information concerning the order and save on time of rechecking with the client. Additionally, the firm could utilize computer systems that provide attendants with tips to aid employees when accessing the menu to make informed and faster decisions. Such an initiative could prompt attendants to answer precise questions about size, flavor, temperature, and location, thus making it easy for the barista. Generally, the firm should invest in quality computer systems and train their employees on customer handling processes. Eventually, Wild Dog Coffee Company will offer clients quality coffees in all the shops and benefit from the expansion.

Inventory

Wild Dog Coffee Company should exercise quality control, thus ensuring baristas prepare accurate orders and offer superior coffee beverages. Measuring each coffee ingredient will help manage operation costs, manage the inventory, and provide consistent products to all clients. For instance, if the baristas know how much milk or flavor is required in each cup, they can easily predict how long the inventory will run. However, the following estimations will be complex for the baristas to track the stock, and the practice could compromise quality service delivery. Additionally, measuring the ingredients will enable the management to plan how much an inventory can last, thus avoiding inconveniencing clients. For instance, if the firm does not keep the stock in check, they may lose a flavor that many clients prefer thus lose them. Therefore, to improve customer service, the company should train the employees to embrace the new practices, including authentic ingredients.

Baristas should measure the flavored syrups based on each drink’s pump. The practice would ensure that the baristas prepare beverages faster and ensure accuracy while delivering clients’ orders. For instance, clients may experience different tastes of the same order on various occasions, despite getting service from the same barista. The variation can be due to other estimated portions which influence the taste. Currently, baristas measure milk by sight while mixing it on a latte in a milk frothing pitcher. The practice makes the measurements more of an estimate, which contrasts using correct milk amounts. Therefore, baristas should use actual measurements instead of the forecast, thus ensuring precise quantities of milk and tracking the inventory. Additionally, the practice will enhance the integrity of the coffee, thus offering clients uniform tastes on all orders at any time.

Quality

When preparing a latte beverage, baristas should stretch the milk to enhance the quality of their products. Although the procedure is delicate, following it ensures the firm prepares quality beverages. For instance, overeating milk produces foam that compromises the integrity of a perfect beverage. Similarly, underheating the milk also reduces the quality of the latter. Currently, the company uses an analog thermometer that allows a wide range of temperature variance in the preparation process. Therefore, the firm should implement a digital thermometer that has a beeping notification, thus creating a constant update to the baristas. The thermometer could help the firm track milk and beverages temperatures at all times, ensuring they offer clients the appropriate order temperatures. The beeping feature will notify baristas to monitor the products if they are distracted while executing other duties. The practice will enhance order taking and help the baristas maintain precision by measuring the milk before purring it into a frothing pitcher.

Additionally, keeping the milk in inappropriate temperatures prevents it from forming a smooth texture once mixed with the flavor. Therefore, stretching the milk ensures the barista prepares beverages in the right textures. Furthermore, the practice alters the overall taste of the coffee. For instance, when coffee is heated to higher temperatures, the components of the milk expand, thus enhancing bites of the flavor. As a result, clients prefer specific temperatures, hot, cold, or mixed due to their corresponding tastes. Therefore, using the modern thermometer will ensure clients get their coffee at the right temperature, complementing their expected quality. As a result, they will remain loyal customers, and the company will benefit.

Generally, Wild Dog Coffee company follows practices that ensure average services to clients. Therefore, perfecting those practices will allow the two shops to run at a maximum capacity and attract new clients. For instance, the firm serves clients who are primarily in a hurry. According to the analysis, occasionally, some baristas take longer to attend to clients. Therefore, reducing the duration for serving orders to strictly two and three minutes would significantly impact the company sales. Training employees and the management team in various fields would increase their work efficiency. For instance, if all employees are taught how to repair the coffee machines, they would help in times of breakage and save the firm’s management costs and clients’ times. The practice could generally increase the efficiency of the firm. Additionally, training the management team will ensure they implement feasible practices and make informed decisions. Furthermore, implementing modern procedures and systems will enhance receiving orders from clients, increase efficiency and ensure accuracy. Following the new techniques and recommendations will help the firm improve its functions in the two shops, ensure customer satisfaction and eventually increase profitability.

References

Aadil, R. M., Madni, G. M., Roobab, U., ur Rahman, U., & Zeng, X. A. (2019). Quality control in beverage production: An overview. Quality control in the beverage industry, 1-38.

ASQ. (2019). Control chart. Retrieved from https://asq.org/quality-resources/control-chart

Aupiais, S. (2018). Barista Basics: How to Make an Espresso in 14 Steps. Perfect Daily Grind. Retrieved 16 February 2022, from https://perfectdailygrind.com/2018/01/barista-basics-how-to-make-an-espresso-in-14-steps/

Aupiais, S. (2018). Barista Basics: How to Texture Milk in 14 Steps. Perfect Daily Grind. Retrieved 16 February 2022, from https://perfectdailygrind.com/2018/02/barista-basics-how-to-texture-milk-in-14-steps/.

Beukes, J., Prinsloo, J. J., & Pelser, T. G. (2018). Customer Service Expectations from South African Alcoholic Beverage Suppliers. Alternation Journal, 25(1), 127-153.

Business processes for building a system. Tightops.com. (2020). Retrieved 16 February 2022, from https://tightops.com/business-process/.

Effendy, F. H., Khuzaini, K., & Hidayat, I. (2019). Effect Of Service Quality, Price And Store Atmosphere On Customer Satisfaction (Study On Cangkir Coffee Shop In Surabaya). Ekspektra: Jurnal Bisnis dan Manajemen, 3(2), 123-148.

Hessing, T. (n.d) Cause and Effect Diagram (aka Ishikawa, Fishbone). Six Sigma Study Guide. Retrieved 16 February 2022, from https://sixsigmastudyguide.com/cause-effect-diagram-aka-ishikawa-fishbone-herringbone-fishikawa/.

Priniotakis, G., & Argyropoulos, P. (2018, December). Inventory management concepts and techniques. In IOP Conference Series: Materials Science and Engineering (Vol. 459, No. 1, p. 012060). IOP Publishing.

write

write