Abstract

Inventory management is one of the critical aspects of supply chain flow at this time when global commerce is fast-paced. In today’s corporate world, most companies have used AI to analyze their inventories to track trends within the real world of supply management, raw materials, and general warehousing operations. Supply chain managers have the mandate of ensuring that they can make fast adjustments to ensure the proper flow of goods. Most of these managers use big data to foster the future operations of their businesses, and also, through their predictive analysis, they have the capacity to spot prevailing trends early. Even as a result of incorporating these features, the global supply chain is still subjected to several layers of complexity as far as inventory control is concerned, and that is to say that as a result of the logistical and cost challenges that were faced in the previous years, the companies have now decided to impose certain policies that foster discipline in their operations. Leveraging systems from big data, AI, and machine learning enables supply chain managers to meet the increased company demands and keep pace with the speed of fulfillment. However, a few doubts still resurface on the importance of a responsive and agile supply chain, especially after the COVID-19 pandemic. Critics hold that creating a responsive and agile supply chain within the business is a benchmark for inventory management and, more specifically, supply chain management in contemporary business today.

Introduction

This report’s analysis will discuss the supply chain management of a reputable industry along with the inventory management associated with it. Inventory, as mentioned earlier, is a crucial part of the supply chain management of any given industry; thus, discovering its essentiality and how the company uses it in the management and driving of their daily activities is of relevance. The specific industry used in this analysis is DHL, which is a family of specialized business units offering an unrivaled portfolio of logistics products and solutions ranging from domestic and international parcel delivery through international express, freight, air express, international express services, and end-to-end supply chain management.

Role and importance of inventory in the supply chain

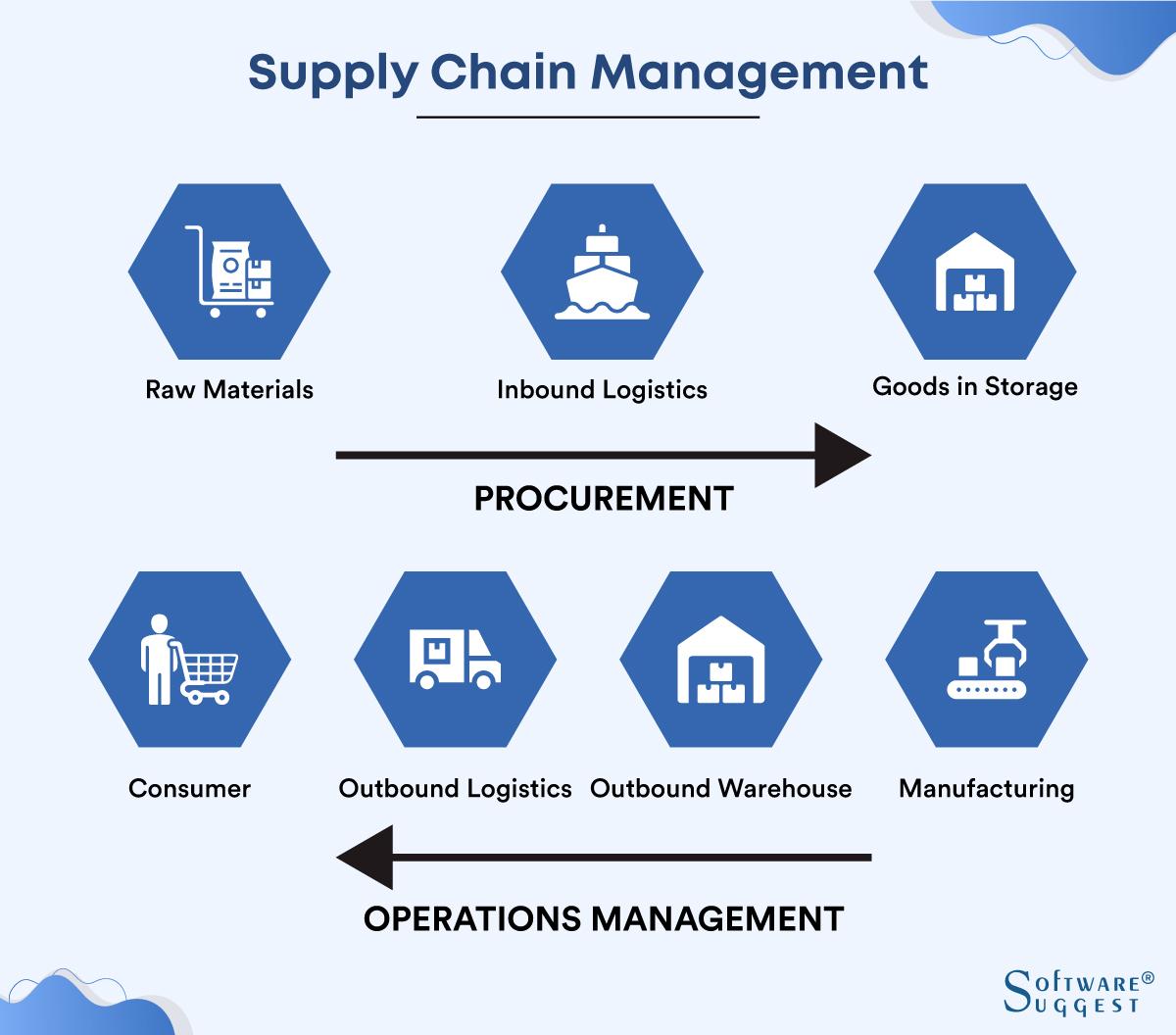

Controlling the flow of goods and materials from suppliers to customers follows a certain distribution channel through value-adding processing. According to Michael and Emine (2019), this is a requirement for all manufacturing businesses to ensure that there is a network of connections and interconnectedness of processes that are concerned with the aspects of organizing, coordinating, and ultimately, the movement of raw materials and finished goods, either as a whole or in part, from the supplier to the customers. Facilitating compelling and efficient supply chain management requires the involvement of more stakeholders who will play key roles along the chain. These stakeholders are not limited to transporters, manufacturers, supply chain managers, product retailers, product wholesalers, vendors, and consumers.

FIG. Group flow of the Supply Chain

The importance of the supply chain is widespread across every industry, as every company’s mandate is to follow a certain supply chain to ensure that its management deems to yield an efficient result (Hugos,2024). If a company endorses a working supply chain, it can serve its benefits in an array of contexts; a typical example is that the given company has the potential to increase its output, which can result in improving its communication systems and fostering corporation not only within the organization but also the third parties. The delays in the supply chain can be carefully omitted or even reduced through the implementation of a thoroughly planned and executed plan.

Inventory refers to all the company products and materials that the business owns and is at its disposal, and can be offered to the customers to gain profits. Fostering relationship building with the customers and the customers is essential in managing the supply chain. So, the most fundamental aspect of the inventory is to balance the demand and supply. Most businesses deal with supplies and exchange consumer needs so as to efficiently manage the reverse flow of the supply chain. The firm is often faced with balancing and meeting consumer needs and channeling them to align with the company goal (Dufay et al.,2023). It is then the mandate of every business to ensure that they concentrate on their inventory to stand out from their competitors. According to Libai et al. (2020), customers’ expectations change daily due to the rise of global demand for a wide range of products. The company’s supply chain, along with its inventory management, needs to be given special attention to remain adamant and, most importantly, stay relevant to survive over the long term.

Approaches to managing inventory

there are different approaches to inventory management that many industries endorse. This section of the report will look at each approach and provide an explanation of how it works. This section will be specific to our selected company, DHL, and give an explanation of how they use the inventory to facilitate their daily activities. DHL has different kinds of inventory techniques depending on the kind of businesses that they are willing to examine. DHL uses many approaches on how they can manage their inventories, and some of the mentioned approaches are not limited to:

VED APPROACH- This method separates inventory items into three groups depending on their vital characteristics. The “V” items refer to those products that are perceived as important and, in the event that they run out, can cause production to be interrupted. The components of the “E” function are necessary for the operation system and always assure that the operation is effective and always on hand. The” D “notion stands for the desirable products, which belong to products that are not necessarily or rather immediately relevant to the production; hence, their availability is characteristic of increasing productivity and decreasing discomfort. DHL is one of the businesses that is capital extensive and so can benefit greatly from the VED approach because of the analysis of its characteristic of analyzing the product depending on their importance.

Just in time-through ensuring that the inventory is maintained and purposely channeled to sell items, it goes without question that this type of inventory enables the businesses to cut waste, hence lowering the expenses associated with the storage and insurance, and there is a chance of liquidating such inventory.

Day sales of inventory, also commonly known as the average age of inventory, typically uses the typical number of days that the business has operated to convert its inventory into sales. The number of days simplifies the inventory liquidity and portrays the duration that the current stock of the organization would survive.

DHL has software to manage its inventories, so considering the nature of today’s businesses, it is imperative to supervise and manage the warehouse’s daily activities. So, it should include stocking talking to ascertain the level of stocks available, tracking shipments, and alerts when the stock reaches their destinations. The system used by DHL divides orders into batches based on their location and logs them into various stages of their progress from arrival to layover in the warehouses. On the other hand, the staff plays a critical role in ensuring that the products are directed in the best way possible to a destination and that the products are required at a given time. The staff have harnessed the omission of errors during shipping and have fostered the completion of orders more quickly within the given timeframes.

Demand variability covid 19 impacts

This section of the paper will outline how demand and variability can lead to either over or under-stocking the inventory when subjected to various circumstances. The last part of the paper will relate situations like the one for covid 19 to change the inventory’s availability.

The supply chain controlling factor can be attributed to the demand variability, and this refers to the difference between the real and the projected development cycles. This is present in every stage of the supply chain, from providing raw materials to production from machines and customer delivery. (Oakden,2019) a circumstance aroused by an unexpected rise in demand on the interrupted flow of goods.

In the supply chain, checking up for inventory is crucial as it shows the level of demand for a particular good. Overstocking is maintaining more inventory than required to satisfy consumer demands. On the Contrary, understocking is a failure to keep enough to meet the customer demands. Instances, where the factor order variability increases while orders shift upstream, are known as the bullwhip effect. The supply chain sector and its demand prediction ratio were severely impacted by COVID-19, to the point where bullwhip occurred. Where it is evident that empty shelves indicate a bullwhip effect. Basic consumer packaged goods (CPG) like hand soap and toilet paper were hard to come by because of consumer stockpiling in response to the outbreak. The massive increase in demand required supply chains to increase production. Orders and demand increase as a company moves up the supply chain (in turn), with wholesalers, suppliers, manufacturers, and so on placing greater orders in response to retailers’ increased orders.

Tools and techniques for managing inventory

This section will outline the tools and techniques many industries use to manage inventories in the supply chain. A typical example of the supply chain will be used to depict their management method. According to Cannas et al. (2023), Software solutions have become a common phenomenon within the supply chain management tool, and it’s proven to be beneficial since they depend on efficient supply chain operations; that said, there are tools and techniques the management of the inventory:

SAP integrated business planning is a real-time supply chain planning feature that helps businesses meet changing consumer demands. The system incorporates aspects of sales and operations, especially in the demand responses, sales and operations, and diversity as capsulated by in-memory computer technology.

Logix platform is another tool, and it is cloud-based to assist companies in manufacturing and logistics. Its streaming operations are in line with warehousing and transhipping. As a result of this, experts within these industries can manage a lot of vendors and also track shipments.

Inventory control(pull)-the supplier manages the consignment on the customer’s property. The stock becomes the customer’s asset as soon as it has been consumed. With the help of this tool, the inventory control would be in line and, more specifically, store a balance between the demand and the excessive inventory costs (Lin et al.,2023)

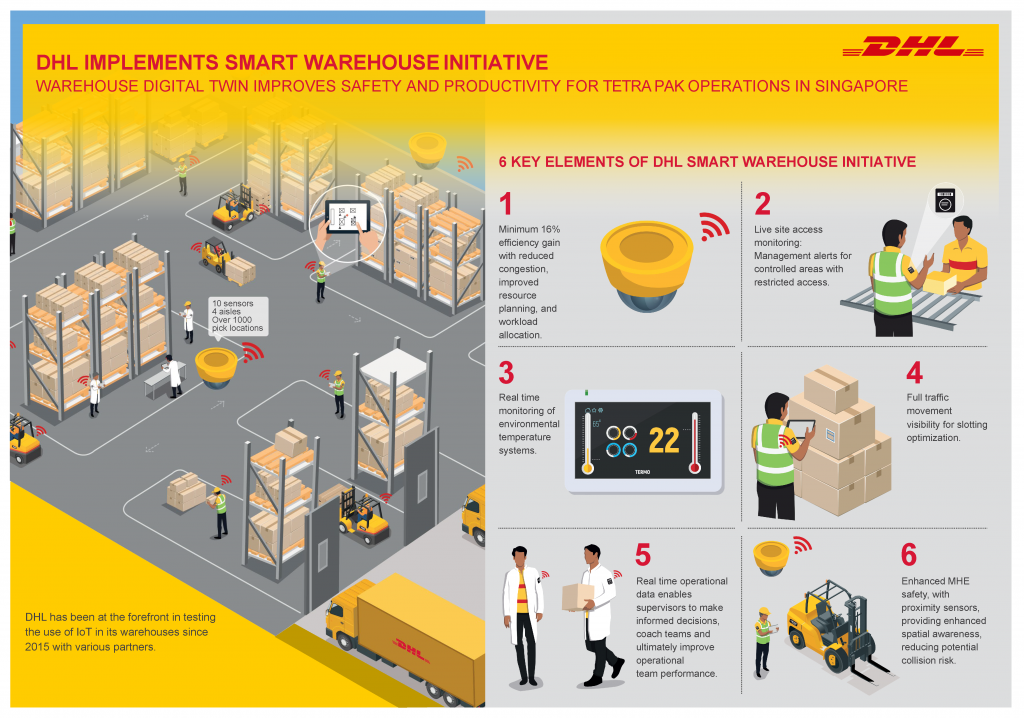

Its experts at DHL have developed innovative technology like the DHL SMART SENSORS for precise geo-tracking. This system uses automated robotics and augmented reality to offer solutions to big data analysis and solutions and real-time and end-to-end supply chain visibility.

DHL, through the r supply chain inventory, dealt with COVID-19 through the use of a proper strategic plan to overcome instances of overstocking or understocking for the organization. As for the new normal, DHL pointed out that they needed flexible and adaptive transportation channels and networks that would be more irregular and influence customers’ tastes to change unexpectedly. Direct-to-consumer sales will rise, and internet buying will become common; as a result, other retail channels and industries will be impacted.

Inventory Design of the DHL

DHL has undergone a series of reforms from being a logistics network planner to transport design and simulation to being operational improvement and inventory analysis and offering a broad range of solutions and skills to support and address accompanying issues. DHL has come up with a system that addresses the issues of supplies and creates integration solutions that foster a customized internal platform offering support towards a standardized manufacturing activity and inbound the automobile environment.

FIG. Inventory Design of DHL

The activities involved are supply timing, supply metering, and restocking to achieve access to supplies. The offer of introducing a unique and web-based supplier integration aims to achieve an integration solution between the company and all DHL supply chain networks. The essence is that DHL aims to create an interconnectedness through this, hence making its operations flexible to foster a real-time manufacturing paradigm to improve both the information through service and product flow at lower costs, hence DHL maximizing its profitability.

Conclusion

In conclusion, this report has widely spoken about how effective an organization is as it uses its inventory supply chain inventories and the outsourcing effect of the changes in the patterns of management systems. COVID-19’s influence changed the way DHL managed its inventory, which came with a digitalized system for managing it. Since then, many companies have implemented such, and the motive for every company is to ensure that they reduce manpower to a considerable level and shift inventory management paradigms to controlling it online with the help of tools for efficiency.

References

Michael, J. F., & Emine, E. K. (2019). Understanding Supply Chain 4.0 and its potential impact on global value chains

Hugos, M. H. (2024). Essentials of supply chain management. John Wiley & Sons.

Dufay, L., Virolle, A., & Gay, U. (2023). Adapting to Pandemic disruptions during the Covid-19: An analysis of DHL’s Strategies for Maintaining Supply Chain Capabilities.

Libai, B., Bart, Y., Gensler, S., Hofacker, C. F., Kaplan, A., Kötterheinrich, K., & Kroll, E. B. (2020). A brave new world? On AI and the management of customer relationships. Journal of Interactive Marketing, 51(1), 44-56.

Oakden,I.(2019).Why Supply Chain Management is Competency-Based and Business Performance Driven.

Cannas, V. G., Ciano, M. P., Saltalamacchia, M., & Secchi, R. (2023). Artificial intelligence in supply chain and operations management: a multiple case study research. International Journal of Production Research, 1-28.

Lin, J., Naim, M. M., & Spiegler, V. L. (2020). Delivery time dynamics in an assemble-to-order inventory and order-based production control system. International Journal of Production Economics, 223, 107531.

write

write