Explain the design process stages and tasks that must be considered for the design of a non-domestic heating system

Buildings should have adequate heating systems to ensure the comfort of their occupants. To create an effective heating system plan, a variety of requirements and issues from the perspectives of customers, users, and the environment must be considered, such as

- Details about the client (e.g., the design proposes)

- An integrated design approach, for example, would be a coordinated approach by another expert from the outline design discipline.

- achieving environmental and energy goals

- ‘The creation of safety nets (for example, on an individual, zone, or centralized level)

- The needs and activities of the building’s occupants (e.g., work patterns in area and time)

- Before investing, certain factors should be taken into account.

- Understanding the client’s goals and requirements is critical for capital costs (e.g., value engineering).

- Continuity

- Any project requires an understanding of the client’s ability to perform routine maintenance(O’Dwyer et al., 2017).

- Systems that are linked to one another (e.g., fire, security, or acoustic consequences of any specific requirement)

- Protection guarantees (e.g., restriction on size and location of any openings)

- Future requirements anticipated (e.g., flexibility)

- Taking into account the aesthetics

- Factors influencing the sourcing process (e.g., time constraints)

- The design brief is a set of guidelines.

Health & Safety

The Health and Safety at Work etc. Act 1974 (HSWA) is the major piece of law addressing occupational health and safety in Hong Kong. The Health and Safety Executive and local authorities (and other enforcing bodies) are responsible for enforcing the Act and other workplace-related laws(Yang et al., 2021).

Design constraints

Building air conditioning systems must consider both users and the environment. Consider heating system efficiency, temperature and humidity control, and zoning. Early involvement optimizes heating system design. Window size, orientation, and thermal mass distribution affect heat demand. Relatively well-ventilated As a result, pre-heating is required. While designing a new heating system, the designer has limited or no control over important architectural features.

Consider plant room layout or network distribution. System integration may be required. Domestic water must be heated separately or concurrently(Long et al., 2020).

Discuss the information that should be included in a design brief for a non-domestic heating system design

Building form

The overall heat transfer coefficient (U-value) controls how much heat escapes the building envelope. Form influences a building’s thermal performance. Thus, the building envelope’s U-value should be used to calculate heat loss. Height, length, and roof type define a building’s shape. Façades of fractals have the same volume but differ in area. The entire facade area to volume ratio (A/V) best predicts building shape. So use the A/V ratio to compute the building’s U-value. It changes with building shape(Menezes et al., 2012). However, even if the floor space remains constant, the façade area can change. Larger windows for daylighting may increase heat loss through glazing. In frigid climates, building design affects heat loss and thermal comfort.

Building Layout

The placement of windows, rooflines and other features on a structure determines its orientation. Oriented buildings rotate to optimize sun and wind energy. Building proximity and tree shade also impact solar gain direction. A window’s size and placement affect solar gain, as do the glazing’s thermal performance and solar heat gain efficiency. Optimal orientation decreases heating needs, energy costs, and pollutants. Effective solar orientation requires a year-round understanding of the sun’s journey(Zapata-Lancaster, 2014).

Seal tightness

As part of the building envelope, Windows affects the thermal and light environment. It enhances window airtightness, reduces air permeability, and improves the thermal environment. The classic heat transfer coefficient is larger than 3W/m2K single glass compared to airtightness. In contrast, the most advanced heat transfer coefficient can reach 0.8W/m2K and airtightness level 8. Air pressurization measures air leakage through building fabric. This is done by varying airflow to a particular building, then measuring any pressure differences that result. Increase the pressure difference range to 50 Pa. To avoid structural damage but counteract moderate wind effects(Ucar & Inalli, 2008).

Insulation by fabric

Thermal bridges form when high thermal conductivity materials cross spaces or insulation. This is evident when a structural element like a floor leading to a balcony breaches a wall. Structures that span strata transfer heat in heat loss per unit length: brick mortar joints and timber frame joints. However, when computing U-values using layer parameters, it is critical to consider bridging(Menezes et al., 2012).

Thermal mass

The heat storage capacity of a building element impacts its temperature response. High thermal capacity reduces summer peak temperatures and hence cooling needs. Temperature drop and re-heating time are reduced. A higher thermal capacity requires a higher plant ratio or a longer weekend pre-heat period.

Utility data

The occupancy schedule determines the heating system design. Dormant or active? How much heat is generated by computers and office equipment? The structure’s criteria are uniform or particular. These considerations may limit alternatives. This may affect heating design. System flexibility should also be considered.

Cost

Expert contractors, contractors, and suppliers provide actual rates when design information becomes available:

- Estimated cost (options studies)

- Project brief and budget preparation.

- Quantity costing (from detailed design to tender).

- Bid (prepared alongside tender documentation).

- A priced paperwork was sent to the contractor.

- It was changed during the tender stage.

- Budget breakdown (for design-build projects).

- Charges (agreed during the defects liability period).

Construction costs, except for early estimates (rather than wider project expenditures incurred by the customer, such as fees, equipment, furnishings, employee relocation costs, and so on). Determining which costs are managed by the cost consultant vs. the client is required(Robinson et al., 2015).

Produce design data for a heating system in a given building

Calculate U-values for a given structure

An increase in U-value is equivalent to an increase in the heat transfer rate of one degree over the material’s one square meter area. It is an important aspect when it comes to building design and material selection(Finck et al., 2018). The lower the U-value, the greater the barrier to heat flow in construction and the lower the heat transfer rate per unit area.

| Material | U-value | Material | U-value |

| Softwood | 0.14 | Normal concrete | 1.89 |

| Hardwood | 0.15 | Reinforced concrete | 2.5 |

| Brick | 0.88 | Low-E double glazing | 2.7 |

| Lightweight concrete | 1.23 | Single glazing | 4.9 |

U- value calculation

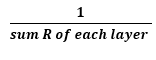

Resistivity =![]()

Thermal transmittance =

| Layer | Thickness | Conductivity | R=d/λ |

| External surface | – | – | 0.0 |

| External render | 0.019 | 0.57 | 0.33 |

| Concrete block | 0.1 | 1.33 | 0.075 |

| Air cavity | – | – | 0.15 |

| Insulation | 0.08 | 0.025 | 3.2 |

| Concrete block | 0.1 | 1.33 | 0.075 |

| Plaster | 0.013 | 0.18 | 0.072 |

| Internal surface | – | – | 0.13 |

| Total resistance | – | – | 3.776 |

Thermal transmittance (U) = ![]() = 0.291

= 0.291

Calculate heat loss for spaces within a given building

Total fabric heat loss flow rate, Qf, is the sum of the U-values of each exterior fabric element multiplied by their respective areas multiplied by the temperature differential between the interior and the outside.

In other words, Qf = (UxAx) T watts – (note: Σ symbol means ‘sum of’)

Thus, the fabric’s contribution to the overall heat loss coefficient is:

Qf/ ΔT = ΣUxAx W K1.

| Element | Area | U-value | Contribution to heat |

| Floor | 48 | 0.291 | 48*0.291 |

| Roof | 48 | 0.16 | 48*0.16 |

| Walls | 80 | 0.35 | 80*0.35 |

| Windows and doors | 26 | 2.00 | 26*2.00 |

| Total | 94.6 |

Assuming that both houses are at the same temperature, there will be no heat loss through the (uninsulated) party wall that separates them. The metal lintels over windows and piping running through walls are examples of additional conduction heat losses dubbed cold bridges(Chinese et al., 2011). However, these will be ignored for the time being. Adding in the heat loss via ventilation is also necessary:

Qv = 0.33 × n × V × ΔT watts

N is the number of air changes per hour (ACH), and the house volume V is the total area of the house (m3). The overall heat loss coefficient as a result of ventilation is:

Qv / ΔT = 0.33 × n × V W K−1

An air change rate equal to 0.5% per hour (which requires relatively airtight construction) is used to calculate how much air needs to pass through the house to keep it cool.

Qv / ΔT = 0.33 × 0.5 × 240 = 39.6 W K–1

As a whole-house heat loss coefficient, the fabric and ventilation components contribute to:

(Qf + Qv)/ΔT = 87.7 + 39.6 = 127.3 W K–1

Calculate the total heating load for a given building

It can be used to describe the amount of heat needed to heat a space and keep it at a specific temperature over a long period (usually over an hour). The heat load is greater in poorly insulated buildings than thermally efficient ones. Heating needs are minimal in a building with high thermal efficiency instead of other types of construction. Around 15kWh/(m2a)) is used in Passive houses, which is about 10% of what is used in conventional buildings(Yang et al., 2021).

Capacity required for cooling

Alternatively, the term “heat load” can be used to describe the amount of calculated thermal energy required to determine a cooling system’s ability to keep a building or space at or below a set temperature target. To do this, all possible heat-producing activities (heat sources) in that building or space must be considered, including solar radiation, people, machines, lighting, kitchens, and computers.

A data center, for example, which houses computers and servers, will generate heat as a result of the electrical load it is carrying. The cooling system of the building will have to take on this additional heat load and dissipate it to the outside. Once the heat load has been determined, HVAC engineers can begin designing the cooling system to keep the space at the desired temperature. The following formula can be used to estimate the heat load in offices with two to three people and three to four computers:

Size (in meters) multiplied by 141 = BTU heat load.

So, for a 5m x 4m x 3m room, the BTU calculation is 60 > x 141 = 8,460.

A heat load is calculated by multiplying an object’s length, width, and height by the number of BTUs it produces. Add 500 BTU for each additional person in the household: Since there are now six total occupants, the heat load will increase to: 8,460 BTU plus 4,500 BTU multiplied by 4 equals 10,460 BTU. Kilowatts can also express heat load and heat gain (kW). 1 BTU equals 0.00029307107 kW when converted to kilowatts. As a result, 10,460 BTU is equivalent to 3,065 kW in the previous example(Finck et al., 2018).

Discuss suitable alternative heating strategies for a given building

Heat pumps

When it comes to providing hot water and heating your home, Heat Pumps are the most cost-effective alternative. They can heat your home to three times as efficiently as a furnace. As a result, they generate three times as much heat as they consume. Using solar power to power your heat pump further reduces your home’s environmental impact while increasing its long-term viability.

Ground-based Heat Pumps

Ground Source Heat Pumps extract heat from the earth and convert it into usable heat energy for your home using either a deeper vertical borehole or a shallow but long trench. The main drawbacks of these systems are their high initial installation costs and the requirement for a certain amount of outdoor space, regardless of the design. The plant room for a ground source heat pump takes up very little space on the inside. This can be planned for if you’re starting a new construction project. However, depending on the system you choose, it may have little to no impact on your existing interior(Ucar & Inalli, 2008). Ground Source Heat Pumps are the quietest heating system compared to other alternative heating systems and traditional fossil fuel-powered systems. However, this will depend on your exact system. Installation near your living space or bedrooms or a neighbor’s property may benefit from this feature. Additionally, GHSPs have a lifespan of 20-25 years, making them far more durable than a traditional boiler. According to GoCompare, it has a lifespan of up to 15 years but only half that for an efficient one.

Air Source Heat Pumps

Ground Source Heat Pumps and Air Source Heat Pumps are alternative heating systems. Rather than taking heat from the ground, these systems take heat from the surrounding atmosphere and then compress it to raise the temperature to a usable level for heating your house and providing hot water (up to 55 degrees). ASHPs require less outdoor space than GSHP systems, but the fan unit still needs open space to sit. There is a plentiful supply of air around it – so, for example, they can’t be placed in a garage or an outside building. You’ll also need to build an indoor plant room into your system design. ASHPs are less expensive to install and have a longer lifespan than GSHPs, typically 15 to 20 years. ASHPs have a bad rap for being obtrusive, but that’s not entirely accurate. Because of the above-ground fan used in the pump, ASHP systems are noisier than GSHPs(Menezes et al., 2012). However, they aren’t much louder than any other heating system when properly designed and installed. The Renewable Heat Incentive (RHI) program accepts either type of heat pump

Biomass boiler

The efficiency of biomass boilers is similar to that of conventional boilers, at around 90%. They do not use gas but rather wood logs or pellets made from other types of wood waste as a fuel source. This alternative healing method is carbon neutral because of the carbon absorbed by the tree over its lifetime. According to waste management giant VEOLA, a secondary benefit of this practice is to divert waste wood from landfills, where it would otherwise end up an estimated 9 million tons per year. Biomass boiler fuel, such as logs and pellets, is often less expensive than fossil fuels and has less price volatility because it can be sourced locally(Finck et al., 2018). Off-grid rural residents may even be able to use their own land’s logs as a free fuel source, allowing them to reduce their operating expenses drastically. With a Biomass Boiler, the upfront cost can range from $5,000 for the smallest domestic system to $15,000 to $20,000 for an automated, fully-automated system. Renewable Heat Incentive (RHI) will help you recoup some initial investment, but it won’t be cheap upfront.

Solar thermal panels

This is the least efficient alternative heating system, with 70% to 90% efficiency. However, it remains a popular choice. The RHI covers the long-term costs of a solar thermal panel system so that the initial installation costs can be offset over time. Instead of heating systems, solar thermal panels are best suited for providing hot water. Because of our mild winters here in the Hong Kong, it’s common to use a biomass boiler to supplement the main supply(Chinese et al., 2011). If you want to save money and reduce your carbon footprint, this alternative system is worth trying

References

Chinese, D., Nardin, G., & Saro, O. (2011). Multi-criteria analysis for the selection of space heating systems in an industrial building. Energy, 36(1), 556–565. https://doi.org/10.1016/J.ENERGY.2010.10.005

Finck, C., Li, R., Kramer, R., & Zeiler, W. (2018). Quantifying demand flexibility of power-to-heat and thermal energy storage in the control of building heating systems. Applied Energy, 209, 409–425. https://doi.org/10.1016/J.APENERGY.2017.11.036

Long, O. Y., Sai Gautam, G., & Carter, E. A. (2020). Evaluating optimal U for 3d transition-metal oxides within the SCAN+ U framework. Physical Review Materials, 4(4), 045401. https://doi.org/10.1103/PHYSREVMATERIALS.4.045401/FIGURES/10/MEDIUM

Menezes, A. C., Cripps, A., Bouchlaghem, D., & Buswell, R. (2012). Predicted vs. actual energy performance of non-domestic buildings: Using post-occupancy evaluation data to reduce the performance gap. Applied Energy, 97, 355–364. https://doi.org/10.1016/J.APENERGY.2011.11.075

O’Dwyer, E., De Tommasi, L., Kouramas, K., Cychowski, M., & Lightbody, G. (2017). Prioritised objectives for model predictive control of building heating systems. Control Engineering Practice, 63, 57–68. https://doi.org/10.1016/J.CONENGPRAC.2017.03.018

Robinson, J. F., Foxon, T. J., & Taylor, P. G. (2015). Performance gap analysis case study of a non-domestic building. Proceedings of the Institution of Civil Engineers: Engineering Sustainability, 169(1), 31–38. https://doi.org/10.1680/ENSU.14.00055/ASSET/IMAGES/SMALL/JENSU169-0031-F3.GIF

Ucar, A., & Inalli, M. (2008). Thermal and economic comparisons of solar heating systems with seasonal storage used in building heating. Renewable Energy, 33(12), 2532–2539. https://doi.org/10.1016/J.RENENE.2008.02.019

Yang, L., Yang, J., Liu, Y., An, Y., & Chen, J. (2021). Hot box method to investigate U-values for straw bale walls with various structures. Energy and Buildings, 234, 110706. https://doi.org/10.1016/J.ENBUILD.2020.110706

Zapata-Lancaster, G. (2014). Low carbon non-domestic building design process. An ethnographic comparison of design in Wales and England. Structural Survey, 32(2), 140–157. https://doi.org/10.1108/SS-07-2013-0029/FULL/XML

write

write