1 Abstract

This study was purposed to examine how using different fracturing fluids and additives impacts the effectiveness and environmental consequences of hydraulic fracturing operations. Hydraulic fracturing is also utilized in low-permeability sediments and other subsurface formations for increased vapor extraction efficiency and remediation of contaminated sites. The process of hydraulic fracking is preceded by site preparation and drilling preliminary stages. The fracking fluid used in the injection is composed of a mixture of sand, water, and different chemicals with a range of toxicity and is first pumped into the earth’s surface through the drilled well bore. Rushing the fluids over the layers of the shale rock crevices result in high intensity, pressure, and chemicals forced through the crevices, and cracks of shale rock, allowing the production of oils and gases. Water contamination due to fracking arises from unprecedented leakages in storage areas, leaks from injection wells, and residuals applied to the land surfaces. Clearing of land leads to land leads to massive loss of habitat, increased habitat edges along the landscapes, and unprecedented land fragmentation. Greenhouse gases produced during fracturing contribute to air pollution. Fracturing fluids have the potential to increase pressure in the fissures and faults and counter the effects of frictional forces, increasing the chances of earthquakes. Adopting a design strategy with several casing layers will limit the possibility of surface leakages, thereby reducing water contamination. The effects of earthquakes can be mitigated by adopting proper seismic protocols and adjusting injection rates. The effects of habitat disturbance could be reduced by adopting land reclamation procedures and using effective drilling equipment.

Keywords: Fracturing, fracturing fluids, shale rock, environmental impact, mitigation strategies

2 Introduction

Fracking (hydraulic fracking) involves the injection of sand, water, and chemicals into the wells to break up underground bedrock and free up the gas and oil reserves.[1]. The fracking process is purposed to form new rock fractures, increasing the extent, size, and existing connectivity to extract trapped oils and gas. The process is a well-stimulation technique commonly used with low-permeability rocks, such as shale, tight sandstone, and coal beds, for increased gas and oil flow into wells.[2]. In addition, hydraulic fracturing is also utilized in low-permeability sediments and other subsurface formations for increased vapor extraction efficiency and remediation of contaminated sites. The practice of hydraulic fracking accounts for only a small part of the process of completing, drilling, and producing gas and oil wells. However, since fracking involves the injection of chemical solutions into the ground, freeing up the gas and oil resources, it is attributed to some environmental impacts. Therefore, It is imperative to understand these impacts and design effective mitigating strategies to reduce them for effective, efficient fracking. This study is purposed to examine how different fracturing fluids and additives impact the effectiveness and environmental consequences of hydraulic fracturing operations.

3 Description of Challenge/Theoretical Aspect

3.1 Process of Fracking

The process of hydraulic fracking is preceded by site preparation and drilling preliminary stages. Site preparation involves ensuring that the drilling site is properly accessible and the drilling equipment has been well-graded. The roads and drilling pads are built and properly maintained by spreading stones on impermeable liners to prevent unprecedented spills and allow effective draining of any rain that may be falling on the site[3]. Drilling can be either vertical drilling or horizontal drilling. In vertical drilling, a hole is drilled straight downwards to the ground, and extended past a freshwater aquifer, approximately 300 feet. The drill pipe is later removed from the site and replaced with a surface casing (steel pipe). After that, cement is placed into the casing and settled between the borehole, and the casing, providing a form bond and preventing unprecedented movements of fluids. In addition, this settled cement forms an essential and impermeable protective layer between freshwater sources and the well-bore. Notably, extra casing sections can be incorporated to ensure that there will be no relative movements of gases and oils between the groundwater sources and well-bore layers during the actual fracturing. These extra casings are only necessitated by the nature of the site’s geology and the drilled well’s depth. In horizontal drilling, a hole is vertically drilled in a well up to the right depth, the “kick-off point,” after which the well bore is curved to form a horizontal drill.[4]. This type of drilling is more appropriate compared to vertical drilling as it allows drilling of several laterals from a single point, minimizing the scale, and impact of the activity to the surface above.[5]. Once the required depth has been achieved, the drilling pipe is removed. The pipe is then replaced with a steel casing, inserted the full length of the well bore, and cement inserted, just like in the vertical drilling. Once the drilling process is completed, the actual hydraulic fracturing process is commenced.

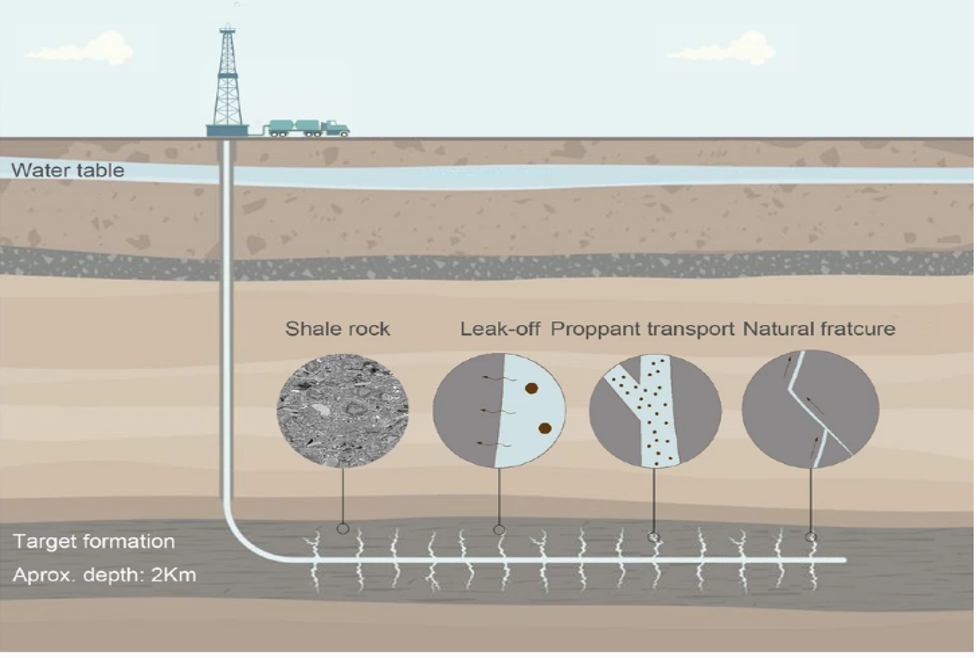

The process of hydraulic fracturing for gas and oil production from the reserves through injection pressuring is commenced when the preliminary stages have been completed. Figure 1, presented below, illustrates all the stages involved in the fracking process.

Figure 1: Diagrammatic Presentation of Hydraulic Fracturing Process[6]

The fracking fluid, composed of a mixture of sand, water, and different chemicals with a range of toxicity, is first pumped into the earth’s surface through the drilled well bore. When pumped, the high intensity and pressure of fracking fluid makes it rush into the layers of the shale rocks, crevices, and cracks.[7]. In the process, the chemicals contained float on the surface of the liquid, and as a result of high intensity, and pressure, these chemicals will be forced through the crevices and cracks of shale rock. At some point, the shale rock’s internal pressure makes the fluid flow back toward the surface. This fluid can be collected into a specially designated tank and later transferred into the treatment plant. Notably, as the fluid retreats, the crevices and cracks in the shale rock may attempt to close due to pressure drop. Proppants are left within the cracks of the shale rocks and may fracture as water retreats. The proppants usually open up the fractures of the shale rock, preventing them from closing further. Importantly, due to the immersive pressures in the adjacent shale rocks, the fracturing proppants must have a high crush factor and strength. The proppants change the rheological properties of the fluids. Notably, the nature of proppants distribution right after the flow back impacts the final network of the fracturing stages.[8]. Once the propping stage is completed, the production of gases and oil is commenced. The oils and gases flow freely from the fissures of the shale rock in the well bore, and in the process, fracturing fluid recovered. In the production of these fluids, approximately 25 to 75 % of the fluid is usually recovered and recycled for later use in further operations of hydraulic fracturing or disposed of altogether[9]. Past studies have shown that the industry of petroleum has been severely affected by unprecedented leak-offs occurring in the hydraulic fracturing.[10]. The volume of fracturing fluids that are collected in the reservoirs is highly dependent on the nature of the fluid involved, and the formation properties, with the leak-off percentages ranging from 10% to 50% for brittle formation, and from 80% to 99% for soft formation, such as the sandstones[11]. These leak-offs are attributed to significant negative effects on the fracturing processes. High levels of leak-offs in fracturing lead to retardation of process propagation and change of geometry as a result of the reduction of fracturing fluid. In addition, leak-offs lead to increased proppant concentration, affecting their final distribution, hence the volume of fluids collected into the reservoirs.

3.2 Primary Environmental Effects of Fracking and Correlation of Facts

When the entire process of producing oils and natural gas with the imploration of fracturing stimulation techniques is attributed to different primary environmental impacts, including water pollution, air pollution, and habitat disturbance.

3.2.1 Contamination of Water

The underground water can be contaminated in different ways as a result of hydraulic fracturing, including unprecedented leakages in the areas of storage, leaks from the injection wells, and residuals applied to the land surfaces, among others.[12]. Essentially, during hydraulic fracturing, water is usually mixed up with different chemicals to form frack fluids, as highlighted in the preceding sub-section. In addition, the cement casings that ring well bores and pass via the underground aquifers act as the barrier between the shaft and the underground water via the fracking fluids, and the flow of gases could lead to pollution. Essentially, the casing could break or fail during the fracturing process and allow fracking fluids and other naturally-occurring contaminants to mix with the underground waters, polluting the waters.[13]. Additionally, frack fluids may leak directly from the well bore into the water supply, leading to unprecedented build-ups of gases, making such waters unfit for consumption. Furthermore, even if cement casings were to hold in their position within the well bores during the preliminary and subsequent stages of hydraulic fracturing, the gases and oils produced could travel from the layers of the shale rocks into the water tables through the fractures within the surfaces of the rocks leading to contamination.[14].

The process of drilling and the chemicals used in hydraulic fracking also leads to significant water contamination. Ideally, the wastewater formed while drilling the ground surface has been attributed to the massive killing of ground vegetation in different parts of the world, such as in West Virginia forests. In addition, wastewater has been attributed to the deaths of pets and livestock.[15]. Besides these, some of the chemicals comprising the frack fluid and wastewater of the hydraulic fracking processes have been linked with deleterious health conditions. These chemicals include heavy metals, Toulene, Benze, and 2-butyloxyethanol. Direct interaction or interaction with wastewater containing these chemicals leads to cancerous conditions and massive destruction of plants within the surrounding environments.[16]. Notably, when the fluids have been injected into the ground surfaces, and fissures opened to allow the production of oils and gases, it is not clear what happens to the water used, even though some pieces of past research studies have shown that some of these waters are collected as flow back. The waters remaining within the surface of the ground may flow through underground rocks for longer distances. Considering that these waters are contaminated with different chemicals, it may lead to significant pollution of soils contained over the surfaces above the region where they flow.[17].

3.2.2 Air Pollution

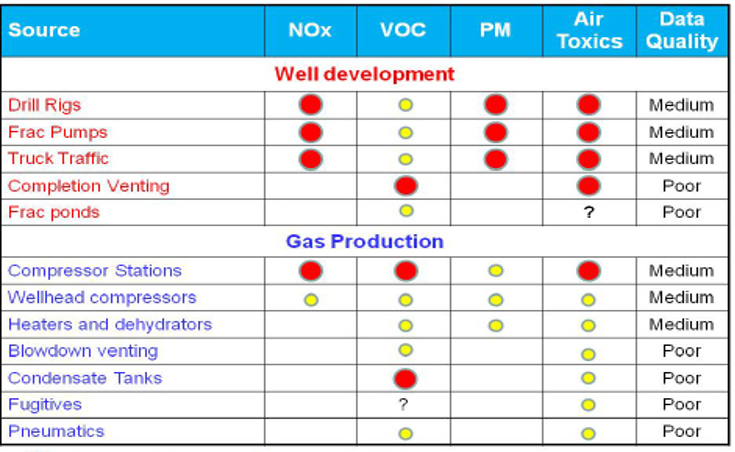

Different air pollutant sources exist in the chain of shale development in different operations, including hydraulic fracking, site preparation, and well bore drilling, among others. Table 1 below presents the major hydraulic fracking-based emissions, categorizing them as main or major sources of pollution, highlighting the nature of pollutants they emit, and assessing the associated quality data.

Table 1: Major Sources of Hydraulic Fracking-based Emissions[18]

Where:

With hydraulic fracking, preceding the production of natural gases, and oils, some of the main pollutants produced include the VOCs (volatile organic compounds), and NOx (nitrogen oxides), among others.[19]. Under the influence of sunlight, these compounds react, destroying the ozone layer, which contributes to significant air problems in the environment surrounding the production site and beyond. Additionally, most of hydraulic fracking operations utilize diesel-powered engines, producing diesel-based particulate matter. These matters and fugitive emissions of methane gases produced during processed oil production and natural gases are composed of greenhouse gases with significant negative environmental impacts. Essentially, greenhouse gases have the inherent potential to trap sunlight heat in the atmosphere leading to unprecedented cases of global warming, disruption of food supplies, and increasing wildfires, among other environmental effects.[20].

3.2.3 Habitat Disturbance

The process of producing natural gases and oils incorporating hydraulic fracturing requires site preparation, as established in the preceding sections of this study. Trees and vegetation would need to be cleared in site preparation to develop a well pad, bore, and space to support the infrastructure and pipelines. These requirements could also necessitate disturbance of pre-existing wildlife within the site, hence lowering habitat availability and quality, both for the resident and the migratory species.[21]. Land clearing tends to be a permanent activity, particularly within the area where pipelines are to be erected, with continued monitoring activities to prevent vegetation growth. Additionally, land where the hydraulic fracturing infrastructure has been placed, is usually reclaimable.

Land clearing leads to massive habitat loss, increased habitat edges along the landscapes, and unprecedented land fragmentation. Ideally, introducing edges in an initially undisturbed habitat has a high potential of changing both the abundance and variety of existing species and increasing the number of species with habitat generalists properties[22]. The number of species that require core vegetative (forest) habitat is reduced. In particular, land fragmentation and the introduction of land edges along the landscapes affect bird species, such as passerines. Moreover, grassland sites containing wells of natural gases have been associated with an increased number of non-native, invasive plants, reduction of ground cover, and unprecedented changes in the properties of soils, potentially contributing to nesting success. Past research studies have established that in Western Virginia and Pennsylvania, regions with s shale development, there has been a significant reduction of forest-interior bird species and increased constitution of synanthropic species over time.[23]. The roads leading to the hydraulic fracturing site create significant hazards to the existing wildlife. Ideally, road construction activities tend to create movement barriers for herpetofauna, and small-sized mammals, which may lead to isolated sub-populations. In addition, these roads may become corridors, leading to the massive spreading of invasive species and causing significant native habitat losses over time.[24].

Besides these, hydraulic fracturing leads to noise disturbances. The compressor stations for oil and gas production have the potential of producing noises between 75 dBA and 105 dBA continuously, which can be detected at a distance of approximately 1 km from the site of production.[25]. Such high noise levels have been found to affect certain species of birds, including passerine birds. This anthropogenic noise could also disrupt the mating calls and territorial distribution of eastern bluebirds and other bird species.

3.2.4 Earthquakes

Fluids injected into the ground during hydraulic fracturing have the potential to increase pressure in the fissures and faults and counter the effects of frictional forces, leading to earthquakes.[26]. Additionally, past research studies have revealed that non-pressure stimulated hydraulic fracturing operations with low injection pressures lead contributes to shallow forms of earthquakes.[27].

4 Mitigation Strategies

Different measures could be adopted to prevent or minimize the magnitude of fluid leakages and flowbacks leading to water contamination. Some of these measures could be advanced monitoring of the systems and increased casing during the design stages. Ideally, adopting a design strategy with several casing layers will limit the possibility of surface leakages. This design can be implemented through effective, high-standard cementing, enabling effective separation of the drilled well bore, shale rocks from the formations, and waters in the immediate surroundings. On the other hand, continued monitoring of the whole hydraulic fracturing system through advanced acoustic technologies could allow timely detection of all potential leaks and flow backs. Using modern technologies in drilling and powering hydraulic fracturing systems will ensure reduced contents of greenhouse gases produced, effectively reducing air pollution effects.

The effects of habitat disturbance could be reduced by adopting land reclamation procedures and using effective drilling equipment. Ideally, when drilling equipment with low noise levels is used, the noise levels will be precisely low, increasing the abundance levels of species, varieties, and health conditions. On the other hand, land reclamation can only be achieved once the oil and gas production has been completed in a site. Effective land reclamation ought to involve surface re-grading to restore the top soils and re-vegetation.

The effects of earthquakes can be mitigated by adopting proper seismic protocols and adjusting injection rates. By adopting low injection rates, it will be possible to reduce the pressure levels in the fissures and faults and increase frictional forces, thereby reducing the magnitude of earthquakes. With effective seismic protocols and low injection rates, non-pressure stimulated hydraulic fracturing operations will be possible, with minimal risks of earthquakes.

5 Significant Findings

5.1 Conclusion

This research study has examined how using different fracturing fluids and additives impacts the effectiveness and environmental consequences of hydraulic fracturing operations. Hydraulic fracturing has been presented as a critical component in the industrial production of oils and gases, with significant environmental impacts. Primary effects of water contamination, air pollution, earthquakes, and habitat disturbance were comprehensively explored, detailing what pertains to each and significant mitigating strategies that can be adopted for effective, efficient fracking.

5.2 Limitations of the Investigation

Despite this study providing an understanding of the process of fracturing and the associated environmental impacts in detail, there needed to be more data. Ideally, the records of sources of environmental pollution were backed by something other than published data from different parts of the world in which these operations are carried out, limiting the scope of the study. Additionally, considering that the production of natural gases and oils with the imploration of fracking techniques is driven by the nature of the land, the content of fluid resources, and the market, some of the suggested mitigating strategies against them could not necessarily hold in certain parts of the world, for instance, the use of advanced acoustic technology in production. It is imperative to consider these factors while instituting mitigating strategies.

6 References

Pollard, J. A., & Rose, D. C. (2018). Lightning Rods, Earthquakes, and Regional Identities: Towards a Multi-Scale Framework of Assessing Fracking Risk Perception. Risk Analysis, 39(2), 473–487. https://doi.org/10.1111/risa.13167

Pichtel, J. (2016). Oil and Gas Production Wastewater: Soil Contamination and Pollution Prevention. Applied and Environmental Soil Science, 2016. https://doi.org/10.1155/2016/2707989

Wang, Q., Yin, X., Jiang, C., Jiang, C., Zhang, Y., Zhai, H., Zhang, Y., Lai, G., & Yin, F. (2021). Research status of earthquake forecasting in hydraulic-fracturing induced earthquakes. Earthquake Science, 34(3), 286–298. https://doi.org/10.29382/eqs-2021-0016

Langlois, L. A., Drohan, P. J., & Brittingham, M. C. (2017). Linear infrastructure drives habitat conversion and forest fragmentation associated with Marcellus shale gas development in a forested landscape. Journal of Environmental Management, 197, 167–176. https://doi.org/10.1016/j.jenvman.2017.03.045

Caldwell, J. A., Williams, C. K., Brittingham, M. C., & Maier, T. J. (2022). A Consideration of Wildlife in the Benefit-Costs of Hydraulic Fracturing: Expanding to an E3 Analysis. Sustainability, 14(8), 4811. https://doi.org/10.3390/su14084811

Liu, S., & Ott, W. K. (2020). Sodium silicate applications in oil, gas & geothermal well operations. 195, 107693–107693. https://doi.org/10.1016/j.petrol.2020.107693

Muther, T., Qureshi, H. A., Syed, F. I., Aziz, H., Siyal, A., Dahaghi, A. K., & Negahban, S. (2021). Unconventional hydrocarbon resources: geological statistics, petrophysical characterization, and field development strategies. Journal of Petroleum Exploration and Production Technology. https://doi.org/10.1007/s13202-021-01404-x

Li, Y., Hu, W., Zhang, Z., Zhang, Z., Shang, Y., Han, L., & Wei, S. (2021). Numerical simulation of hydraulic fracturing process in a naturally fractured reservoir based on a discrete fracture network model. Journal of Structural Geology, 147, 104331. https://doi.org/10.1016/j.jsg.2021.104331

Hossain, E. (2018). Directional and Horizontal Drilling Problems. Drilling Engineering Problems, and Solutions, 497–547. https://doi.org/10.1002/9781118998632.ch10

Chen, B., Barboza, B. R., Sun, Y., Bai, J., Thomas, H. R., Dutko, M., Cottrell, M., & Li, C. (2021). A Review of Hydraulic Fracturing Simulation. Archives of Computational Methods in Engineering. https://doi.org/10.1007/s11831-021-09653-z

Mahmud, H. B., Ermila, M., Bennour, Z., & Mahmud, W. M. (2020). A Review of Fracturing Technologies Utilized in Shale Gas Resources. In www.intechopen.com. IntechOpen. https://www.intechopen.com/chapters/72128

Roundtable on Environmental Health Sciences, Research, and Medicine, Board on Population Health and Public Health Practice, & Institute of Medicine. (2014, December 30). Water Quality. Nih.gov; National Academies Press (US). https://www.ncbi.nlm.nih.gov/books/NBK201899/

Shrestha, N., Chilkoor, G., Wilder, J., Gadhamshetty, V., & Stone, J. J. (2017). Potential water resource impacts of hydraulic fracturing from unconventional oil production in the Bakken shale. Water Research, 108, 1–24. https://doi.org/10.1016/j.watres.2016.11.006

Roundtable on Environmental Health Sciences, Research, and Medicine, Board on Population Health and Public Health Practice, & Institute of Medicine. (2014, December 30). Air Quality. Nih.gov; National Academies Press (US). https://www.ncbi.nlm.nih.gov/books/NBK201897/

Malhi, Y., Franklin, J., Seddon, N., Solan, M., Turner, M. G., Field, C. B., & Knowlton, N. (2020). Climate change and ecosystems: threats, opportunities and solutions. Philosophical Transactions of the Royal Society B: Biological Sciences, 375(1794), 20190104. Royal Society Publishing. https://doi.org/10.1098/rstb.2019.0104

Cao, W., Sevket Durucan, Shi, J.-Q., Cai, W., Korre, A., & Ratouis, T. (2022). Induced seismicity associated with geothermal fluids re-injection: Poroelastic stressing, thermoelastic stressing, or transient cooling-induced permeability enhancement?102. https://doi.org/10.1016/j.geothermics.2022.102404

[1] Pollard, J. A., & Rose, D. C. (2018). Lightning Rods, Earthquakes, and Regional Identities: Towards a Multi-Scale Framework of Assessing Fracking Risk Perception. Risk Analysis, 39(2), 473–487. https://doi.org/10.1111/risa.13167

[2] Muther, T., Qureshi, H. A., Syed, F. I., Aziz, H., Siyal, A., Dahaghi, A. K., & Negahban, S. (2021). Unconventional hydrocarbon resources: geological statistics, petrophysical characterization, and field development strategies. Journal of Petroleum Exploration and Production Technology. https://doi.org/10.1007/s13202-021-01404-x

[3] Li, Y., Hu, W., Zhang, Z., Zhang, Z., Shang, Y., Han, L., & Wei, S. (2021). Numerical simulation of the hydraulic fracturing process in a naturally fractured reservoir based on a discrete fracture network model. Journal of Structural Geology, 147, 104331. https://doi.org/10.1016/j.jsg.2021.104331

[4] Li, Y., Hu, W., Zhang, Z., Zhang, Z., Shang, Y., Han, L., & Wei, S. (2021). Numerical simulation of the hydraulic fracturing process in a naturally fractured reservoir based on a discrete fracture network model. Journal of Structural Geology, 147, 104331. https://doi.org/10.1016/j.jsg.2021.104331

[5] Hossain, E. (2018). Directional and Horizontal Drilling Problems. Drilling Engineering Problems, and Solutions, 497–547. https://doi.org/10.1002/9781118998632.ch10

[6] Chen, B., Barboza, B. R., Sun, Y., Bai, J., Thomas, H. R., Dutko, M., Cottrell, M., & Li, C. (2021). A Review of Hydraulic Fracturing Simulation. Archives of Computational Methods in Engineering. https://doi.org/10.1007/s11831-021-09653-z

[7] Liu, S., & Ott, W. K. (2020). Sodium silicate applications in oil, gas & geothermal well operations. 195, 107693–107693. https://doi.org/10.1016/j.petrol.2020.107693

[8] Chen, B., Barboza, B. R., Sun, Y., Bai, J., Thomas, H. R., Dutko, M., Cottrell, M., & Li, C. (2021). A Review of Hydraulic Fracturing Simulation. Archives of Computational Methods in Engineering. https://doi.org/10.1007/s11831-021-09653-z

[9] Mahmud, H. B., Ermila, M., Bennour, Z., & Mahmud, W. M. (2020). A Review of Fracturing Technologies Utilized in Shale Gas Resources. In www.intechopen.com. IntechOpen. https://www.intechopen.com/chapters/72128

[10] Chen, B., Barboza, B. R., Sun, Y., Bai, J., Thomas, H. R., Dutko, M., Cottrell, M., & Li, C. (2021). A Review of Hydraulic Fracturing Simulation. Archives of Computational Methods in Engineering. https://doi.org/10.1007/s11831-021-09653-z

[11] Ibid

[12] Roundtable on Environmental Health Sciences, Research, and Medicine, Board on Population Health and Public Health Practice, & Institute of Medicine. (2014, December 30). Water Quality. Nih.gov; National Academies Press (US). https://www.ncbi.nlm.nih.gov/books/NBK201899/

[13] Ibid

[14] Shrestha, N., Chilkoor, G., Wilder, J., Gadhamshetty, V., & Stone, J. J. (2017). Potential water resource impacts of hydraulic fracturing from unconventional oil production in the Bakken shale. Water Research, 108, 1–24. https://doi.org/10.1016/j.watres.2016.11.006

[15] Pichtel, J. (2016). Oil and Gas Production Wastewater: Soil Contamination and Pollution Prevention. Applied and Environmental Soil Science, 2016. https://doi.org/10.1155/2016/2707989

[16] Ibid

[17] Ibid

[18] Roundtable on Environmental Health Sciences, Research, and Medicine, Board on Population Health and Public Health Practice, & Institute of Medicine. (2014, December 30). Air Quality. Nih.gov; National Academies Press (US). https://www.ncbi.nlm.nih.gov/books/NBK201897/

[19] Roundtable on Environmental Health Sciences, Research, and Medicine, Board on Population Health and Public Health Practice, & Institute of Medicine. (2014, December 30). Air Quality. Nih.gov; National Academies Press (US). https://www.ncbi.nlm.nih.gov/books/NBK201897/

[20] Malhi, Y., Franklin, J., Seddon, N., Solan, M., Turner, M. G., Field, C. B., & Knowlton, N. (2020). Climate change and ecosystems: threats, opportunities, and solutions. Philosophical Transactions of the Royal Society B: Biological Sciences, 375(1794), 20190104. Royal Society Publishing. https://doi.org/10.1098/rstb.2019.0104

[21] Caldwell, J. A., Williams, C. K., Brittingham, M. C., & Maier, T. J. (2022). A Consideration of Wildlife in the Benefit-Costs of Hydraulic Fracturing: Expanding to an E3 Analysis. Sustainability, 14(8), 4811. https://doi.org/10.3390/su14084811

[22] Ibid

[23] Langlois, L. A., Drohan, P. J., & Brittingham, M. C. (2017). Linear infrastructure drives habitat conversion and forest fragmentation associated with Marcellus shale gas development in a forested landscape. Journal of Environmental Management, 197, 167–176. https://doi.org/10.1016/j.jenvman.2017.03.045

[24] Malhi, Y., Franklin, J., Seddon, N., Solan, M., Turner, M. G., Field, C. B., & Knowlton, N. (2020). Climate change and ecosystems: threats, opportunities, and solutions. Philosophical Transactions of the Royal Society B: Biological Sciences, 375(1794), 20190104. Royal Society Publishing. https://doi.org/10.1098/rstb.2019.0104

[25] Caldwell, J. A., Williams, C. K., Brittingham, M. C., & Maier, T. J. (2022). A Consideration of Wildlife in the Benefit-Costs of Hydraulic Fracturing: Expanding to an E3 Analysis. Sustainability, 14(8), 4811. https://doi.org/10.3390/su14084811

[26] Wang, Q., Yin, X., Jiang, C., Jiang, C., Zhang, Y., Zhai, H., Zhang, Y., Lai, G., & Yin, F. (2021). Research status of earthquake forecasting in hydraulic-fracturing induced earthquakes. Earthquake Science, 34(3), 286–298. https://doi.org/10.29382/eqs-2021-0016

[27] Cao, W., Sevket Durucan, Shi, J.-Q., Cai, W., Korre, A., & Ratouis, T. (2022). Induced seismicity associated with geothermal fluids re-injection: Poroelastic stressing, thermoelastic stressing, or transient cooling-induced permeability enhancement?102. https://doi.org/10.1016/j.geothermics.2022.102404

write

write