Introduction

The case study provides an overview of the necessity for effective supply chain management to create the required strategies that aid in reducing contaminations or environmental problems to boost the efficiency of supply chain performance and transparency between the concerned parties. This is done to develop the necessary strategies that help in developing the necessary strategies that help in reducing contaminations or environmental issues (Ibrahim & Hamid, 2014). Management of the supply chain needs effective communication and cooperation between all parties involved to minimize disruptions in the supply chain. Despite the vital role of the connection between producers and customers, trade connections are often harmed by a lack of competent testing and refusals to allow imports. It takes a considerable amount of time to win the confidence of customers and to develop new relationships that will remain for a long time. Even However, in the event that there is a problem, it is virtually guaranteed that links will be severed, and as a result, it will be extremely difficult to reconstruct them (Ilankoon et al., 2018).

Contamination in the Bulk Agri‐Commodity Logistics Chain

In the case study of the western Australian Export Grain Industry, the shipment of bulk wheat was contaminated during transport, which led to a broken relationship between the participants. The rejection of contaminated imports was rejected therefore leading to significant financial losses, operational losses and reputational damage to all parties involved. During the shipment of the barley that was from the port of Fremantle to Saudi Arabia where there were quality control checks that showed that the standards for shipping the barley to Saudi Arabia were met, including the additional of Carmoisine, which is a red food die used in the red meat industry which was acceptable in Saudi Arabia. Contamination occurred in the next ship that was carrying high-value noodles wheat from Fremantle to Japan. During departure, all the quality checks were conducted, and the vessel was fully loaded and set to sail. However, after the arrival of the ship in Japan in March 2002, the authorities identified an “objectionable contamination” during unloading. The contamination horrified the Japanese, who were the most important customers of Western Australia’s noodles which led them to contact the grain marketing agent to show their outrage about the contamination. After comprehensive testing revealed that carmoisine-treated grain fragments were the offending contaminant in the grain samples. The ship was ordered to stop unloading its cargo and return to port while investigating the issue. After it was determined that Carmoisine was the offending impurity in the wheat shipment, the whole shipment was declared “distressed” and rejected by Japan. This caused the high-quality grain to be divided among the port and the cargo ship, and no owner to step forward and claim it. The Western Australian market was turmoiled after carmoisine–contamination allegations. The Japanese port also suspended operations which prevented other vessels from berthing. The grain marketers, the Western Australian grain merchants, did not understand why their Japanese clients would object to tiny amounts of food colour, especially since it was an addition that another client did not mind as standard treatment (Mangan et al., 2020).

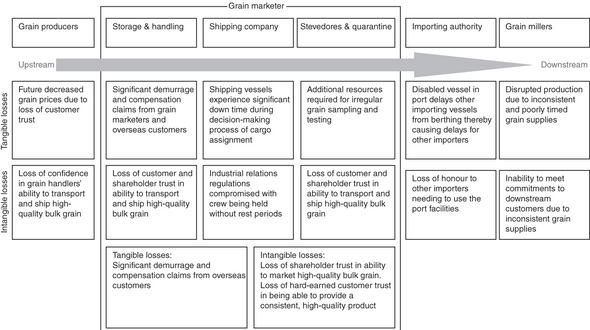

The contamination issues, for instance, the one that involved Japan, occurred as a result of a lack of proper work by the grain marketers, collaboration and improper communication. Inaccuracies in logistics and quality assurance demonstrated a lack of supply chain management. Tensions between the two companies reached a breaking point after they each blamed the other for their losses. The grain marketer was held responsible for miscommunicating an important part of the exporting contract, while the bulk handler was held responsible for being careless during the assembly and loading of the cargo, for instance, for failing to ensure that each of the traces of Carmoisine was properly cleared out of the port’s conveyor systems. The supply chain management lacked coordination and cooperation when considering the specifics of individual countries. As individual establishments, they were doomed to fail. Despite Japan’s best efforts, the import rejection and subsequent problems at the port damaged the country’s reputation. The loss of a long-term customer of significant value contributed to an increase in the level of mistrust that existed amongst the various components within Western Australia’s grain supply chain. Western Australia is the state that produces the most grain in Australia. A significant portion of an established supply chain was out of sync for a period of time. Figure 1 in the appendices shows its tangible and intangible losses.

Environmental Supply Chain Performance Measurement (ESCPM)

In this case, there was the need to ensure that the relationship between the marketers, which were Western Australia and the Japanese, their clients was to be mended, and a second contamination was to be avoided. There was a need to enhance operations among the marketers, authority and grain producers by enhancing logistics and quality control systems (Mangan et al., 2020). There is a need for the Environmental Supply Chain Performance Measurement (ESCPM), which is necessary for examining the environmental effects of the supply chain. The environmental performance of the suppliers, operations and transport modes were to be monitored, and areas that need improvements were pointed out. Supply chain management processes also outline issues like strategic planning that includes developing working models. For instance, marketers can use the ESCPM to reduce waste and emissions and avoid contamination (Shaw et al., 2021).

Transparency and Sufficiency

The market relationships between Japan and its partners greatly rely on trust and long-term supply chain relationships. It is, therefore, important to note that establishing and sustaining market relationships with Japan may be complex, especially when there is a lack of transparency (Galy, 2021). Collaboration and transparency between supply chain partners are objective ways of resolving conflicts. There is a need for companies to ensure that their supply chain practices align with sufficiency, which involves meeting the basic needs of people without compromising what they need (Galy, 2021). For instance, the grain marketers and the Western Australian grain merchants did not understand why their Japanese clients would object to tiny amounts of food colour, especially since it was an addition that another client, Saudi Arabia, did not mind as a standard treatment. It is, therefore, important for companies to achieve sufficiency and collaborate with stakeholders to address social and environmental challenges. The outcome of the case brought to light the dependency of the grain marketers responsible for trading the wheat and the bulk handler responsible for assembling and loading the cargo. Additionally, the settlement of the case brought to light the precarious nature of the supply chain as a result of the competing worldwide food demand. The partnership between the two businesses had reached its breaking point, with each side pointing the finger of blame at the other for the failures that had occurred (Mangan et al., 2020).

Reducing Carbon Footprints

There is a need for companies to use a variety of best practices to reduce carbon footprints in logistics and supply chains. There is a need for companies to have appropriate quality control measures which would allow them to test and support each other. Improving fleet efficiency and implementing route optimization are examples of ways that may be used in the reduction of carbon footprints (Schanes et al., 2016). Company may also reduce their carbon emissions by using electric vehicles and optimizing routes to reduce transportation time and costs. Firms also need to be prepared to take action in an emergency circumstance, for instance, the one encountered by the marketer and Japan. Firms are obligated to manage safety stock and planning for networks because it enables them to ship and receive goods and services at the intended level, assuming no quality concerns arise (Hual et al., 2011).

Reverse Logistics and the Circular Economy

Reverse logistics describes the procedure of handling the return of items from the final consumer all the way back to their place of origin, often for the purpose of reusing the product or disposing of it. In a circular economy, goods and resources are maintained in use for as long as feasible, reducing the amount of waste produced and the amount of pollution released into the environment. Through its ability to simplify the process of reusing and recycling items and resources, reverse logistics is an essential component in the development of a circular economy (Bernon et al., 2018). Businesses are able to apply reverse logistics methods by developing items that are simple to disassemble, providing take-back programs, and forming partnerships with recycling facilities. For instance, after the grain marketer for the high-quality grain that was rejected by Japan found a new buyer, they incurred enormous financial costs and also difficulties in finding a way the unloaded part of the cargo onto the ship. The Japanese economy relies heavily on imports; therefore, the country’s ports are equipped with state-of-the-art capabilities for offloading bulk cargo but have almost no infrastructure dedicated to loading such ships (Mangan et al., 2020). Therefore, the emergency engineering and demurrage costs associated with unloading bulk cargo into a bulk vessel were quite high. On the other side, Western Australia’s bulk commodities ports are primarily for exporting cargo; therefore, the grain marketer needed to quickly offload the surplus goods to avoid having to return them to the port of origin (Mangan et al., 2020).

Conclusion

The actions that are involved in logistics may represent risks to both the environment and to society; however, these risks can be reduced by proper management of the supply chain. Adopting best practices to reduce carbon footprints, implementing ESCPM, fostering the expansion of the circular economy via reverse logistics, and taking into consideration the advent of humanitarian logistics are all things that might help make logistics operations more efficient and responsible. With supply chain transparency and proper LSCM, it is possible to strike a balance between the needs of all stakeholders and advance the cause of sustainable development.

References

Bernon, M., Tjahjono, B., & Ripanti, E. F. (2018). Aligning retail reverse logistics practice with circular economy values an exploratory framework. Production Planning & Control, 29(6), 483-497.

Galy, E. (2021). Consumer Response to Firms Irresponsible Behavior Research, https://utrgv.hosted.panopto.com/Panopto/Pages/Viewer.aspx?id=4848357f-0432-46be-a6d4-ad2c01725ed0

Hua, G., Cheng, T. C. E., & Wang, S. (2011). Managing carbon footprints in inventory management. International journal of production economics, 132(2), 178-185.

Ibrahim, S. B., & Hamid, A. A. (2014). Supply chain management practices and supply chain performance effectiveness. International Journal of Science and Research, 3(8), 187-195.

Ilankoon, I., Ghorbani, Y., Chong, M., Herath, G., Moyo, T. & Petersen, J. (2018). E-waste in the international context – A review of trade flows, regulations, hazards, waste management strategies and technologies for value recovery, Waste Management, 82, 258-275, https://doi.org/10.1016/j.wasman.2018.10.018

Mangan, J., Lalwani, C. & Calatayud, A. (2020). Global Logistics & Supply Chain Management, 4th edition, Chichester, England: John Wiley & Sons.

Schanes, K., Giljum, S., & Hertwich, E. (2016). Low carbon lifestyles: A framework to structure consumption strategies and options to reduce carbon footprints. Journal of Cleaner Production, 139, 1033-1043.

Shaw, S., Grant, D. B., & Mangan, J. (2021). A supply chain practice-based view of enablers, inhibitors and benefits for environmental supply chain performance measurement. Production Planning & Control, 32(5), 382-396.

Appendices

write

write