1. Company portfolio:

Nissan is a Japan-based international vehicle manufacturing company that manufactures unique vehicles according to its vision and mission. The company already has good ranks in the target market but also wanted to get a competitive advantage for future progress. The company has more than 17 assembling points worldwide that are manufacturing different models of vehicles according to the customers’ desires. The company is always preferred the customer’s demand, due to which the company gives the options of customization to the customer (Takeuchi, 2012). I replied that the customers also preferred Nissan to purchase desired vehicles and contribute to the management of the company’s CSR. The company is working according to a specific vision and mission that are as follow:

1.1 Nissan’s vision:

Nissan’s vision is “enriching people’s lives.” It is why the companies made innovative products for people’s lives (Takeuchi, 2012).

1.2 Nissan’s mission:

Nissan’s mission is “Driving innovation to enrich people’s lives.” The company plans to achieve its mission by modifying the products according to customers’ desires (Takeuchi, 2012).

1.3 Company’s core values:

- The environment: The company is focused on making environment-friendly vehicles, so it becomes easy to overcome pollution (Toma, 2013).

- Safety: The company focuses on the related threats and risks and makes the final products safe for the customers. Safety and precautions are essential for the customer’s life (Schmidt, 2013).

- Dynamic performance: The company focuses on the performance of products and the production department to achieve sustainability in the performance (Toma, 2013).

- Life on board: The company focuses on providing comfort and ease to the customers, so they enjoy innovation in their lives (Schmidt, 2013).

1.4 Company’s strategic goals:

- The vehicles should be safer for the customers.

- The cars should be environmentally friendly.

- The people’s comfort and desires are the company’s priority (Schmidt, 2013).

- The company is focusing on the dynamic performance of the products.

2. Global supply chain:

2.1 Overview of the supply chain in Nissan:

Nissan has a complex supply chain for providing the services globally, including Asia, Europe, Japan, the Middle East, America, etc. It is the reason that the company is highly dependent on supply chain management. Currently, the company is manufacturing different models in more than 17 countries all over the world. Still, the company has to supply the products in more than 132 countries that are highlighted that the assembling plants are less in number due to which the company has to rely on supply chain management. The company has flexible supply chain management because of adopting the particular supply chain according to the host country or region (Schmidt, 2013). In this report, the discussion is about the supply chain of Nissan Titan in the US and Europe. Nissan Titan is assembled in Canton, Mississippi, in the US. The overall product assembling process is classified into three parts: tier 3, tier 2, and tier 1. Tier 3 is about the available raw material for the body and general manufacturing of the vehicles. The company produces the available material of tier 3 in Canton, Mississippi. Tier 2 is the collection of brakes and related spare parts imported from Japan (Toma, 2013). Tier 1 is the major components, including engines and such material. The company has three kinds of machines, including powerful engines, diesel engines, and gasoline engines. The powerful motors are made in America, and the diesel engines are made in Columbus, Indiana. Meanwhile, gasoline engines are made in Tennessee (Schmidt, 2013). After collecting the parts, the vehicle is assembled in Canton, Mississippi, and then supplied to the targeted distribution point.

2.2 Products and services:

The company makes the supply chain management for the transportation of vehicles. The companies were manufacturing different models and made the supply chain according to the requirements of the particular problem. Currently, the company has more than 17 assembling points for manufacturing various models of vehicles. When it comes to Titan, it is assembled in Canton, Mississippi. The company is working according to the ATO strategy. The supply chain regulation can be possible with limited warehouses because the company manufactures the products according to customers’ demands. The next step is the transportation of the products (Takeuchi, 2012). The company classified the transport into three steps: the hinterland connections from assembling point to the exportation seaport, sea shipment, and hinterland connection from importation port to the distribution point. The assembling point is in Canton, Mississippi, and the company uses big trucks for road transportation. After this, the company used the port of Huston for supplying the vehicles. The importation seaport in Europe is the port of Amsterdam (Toma, 2013). Again, the company uses big trucks from providing the products from the port of Amsterdam to Paris, where the distribution point of Nissan is located.

2.3 Organization of maritime and port strategy:

The overall shipment service highlights that the port and maritime strategy is compulsory for supply chain management. The port and naval strategy must be efficient because it is helpful for the management of several risks. The company has a plan to fulfil the customer’s demands and desires (Cariou, 2015). Mainly, the customer is demanding the desired products with rapid delivery. Currently, the company is required 2-3 weeks for shipment services that can be reduced by improving the port and maritime strategy. The selection of suitable ports is beneficial for the hinterland connection. The choice of good ships is helpful for the protection of the products (Cariou, 2015). In short, every single factor of port and shipment service is essential for supply chain management. So, the company has to consider these factors while making the port and maritime strategy.

3. Operations strategy:

3.1 Business and operational strategy:

The company makes a four-year business plan for rapid progress at the end of the fiscal year 2023. The business plan is based on two pillars, including business optimization and cost rationalization. Business optimization is referred to as the process of finding the associated factors that would help increase the company’s business efficiency, productivity, and performance for competing efficiently with the competitors. Nissan has a long history and knows about the attributes of the competitors for operation management and management of the external environment (Jindal, 2011). Therefore, Nissan is also planning to use advanced technology because of its benefits for the business optimization process. Meanwhile, the company is also focusing on cost rationalization. It is the process of managing the costs and related techniques for the economic stability of the company. In this era, the competition between the automotive industries increases, and the company has to maintain the quality and reduce the prices. Therefore, Nissan also has the business strategy to produce zero-emission vehicles and get good ranks in zero-emission cars (Jindal, 2011). Meanwhile, the company plans to reduce the prices that the customer can easily afford because the customer’s affordability is essential for increasing the target audience.

3.2 Process strategy:

Nissan is following the ATO strategy for assembling the products. The little bit of use of MTS is also essential for the company. The company manufactures the products based on customers’ demands, so customizing the vehicles according to the customer’s needs is the company’s fundamental strategy. It is why the customers are satisfied with the company and customize the parts according to their desires (Stone, 2006). The company is continuously manufacturing the cars when it makes sure about the requirements of the customers. In such situations, the MTS model is helpful for the company. Primarily, the company is manufacturing the vehicles according to ATO strategy. It is the strategy according to which the company made the products but has the options of customization according to customers’ needs. The company is already manufactured modified and innovative products, but the customers still want to make changes according to their requirements (Stone, 2006). The ATO strategy is also helpful for the company to increase the target audience that directly impacts the cost rationalization process of the company. The company is also focused on the products because product focus strategy is also the way to critically focus on the products that are helpful to make changes according to customer’s requirements.

The competitive advantage is also essential for the company because of rapid progress. The company is focused on innovation in fuelled vehicles. Nowadays, the trend of hybrid cars is increased, but there is limited competition in fuelled cars. Therefore, the company made the fuelled car in the target market (Witcher, 2008). Thus, innovation is the primary competitive priority. Meanwhile, the company plans to lower the vehicle’s prices, which is also beneficial to compete effectively with competitors. The company gives the option of customization to the customers that are helpful to fulfil the customer demand (Witcher, 2008). Therefore, the company can increase the customer booth by providing the opportunity of customized cars according to customers’ requests.

3.3 Customer relationship process:

The customers are the fundamental pillars of the company’s progress, due to which the company is focused on the customer relationship process. The company is adopting the customer profiling process for focusing on the customer’s demand. The company has the ATO strategy for the customers, according to which the customers can easily customize the products according to their demand (Plakoyiannaki, 2006). Meanwhile, it is a challenge for the company to get an idea about the customer needs. Therefore, the company makes the strategy for getting information about the customers. The company is providing the services in 132+ countries, which made the geographic segmentation for getting the idea about the customer’s needs and preferences. Therefore, the company receives good ranks along with making good relations in a particular country. Meanwhile, the company is also analyzing the customers by using mixed demographic data that is also helpful to reveal the customer’s demand (Plakoyiannaki, 2006). The company also has a complex customer service system for serving the customers mannerly.

3.4 Supplier relationship process:

The company manufactures the final products in more than 17 countries but has to supply the products in more than 132 countries. It is why the company has more than five thousand suppliers for providing the products to the destination. Therefore, the company has to make good relations with the suppliers (Chen, 2017). The company is using the supplier management model for making good relations with the suppliers. It is well known that the suppliers are the third party representing the country on an international level. The suppliers model reveals the needs of the suppliers that have to be fulfilled by the company. The supplier has required the roadmap for transportation and budget for the whole project. The roadmap for vehicles is helpful for the rapid delivery of the products (Chen, 2017). Meanwhile, the budget is beneficial for the extrinsic motivation of suppliers. Therefore, Nissan is fulfilling the supplier’s needs by adopting a supplier management model that directly impacts the management of the supply chain.

3.5 Lean process management strategy:

The company is dealing with local dealers and a vast target audience, due to which the management of wasteful spending is essential for the company. It is also beneficial for the inventory management of the company. Therefore, the company is using the just in time theory to control wasteful spending and inventory management. The lean management strategy is currently helpful for the company in different ways (Puvanasvaran, 2008). The company has a complex team for the supply chain management of the vehicles in more than 132 countries, a significant threat to wasteful spending. It can be managed by the adoption of the Just in the model. The company has the goal to lower the prices of the vehicles for competing efficiently with the competitors. The prices of the products can be controlled with the help of a lean process management strategy. The company also adopts the thin theory along with the adoption of the JIT theory. It increases the efficiency of the poor process management strategy (Puvanasvaran, 2008). When the company combines the lean approach and JIT, it can quickly analyze the customer’s demand and manage the resources and services. Sometimes, the clients and customers are irritated because of JIT and lean management theory, but it is essential for poor process management.

4. Port strategy:

4.1 Description of port and maritime strategy:

The port and maritime strategy are essential for the company to provide the services on an international level. When the company has to export or import huge products such as vehicles, the shipment services are the only option for the company to import and export the products (Lam, 2012). The international vehicle manufacturing companies have port and maritime strategies for importing and shipping the products. When the company makes the port and marine strategies, there is a need to consider the three aspects of the port and maritime system, including the transport perspective, shipment perspective, and the selection of deep seaports. The overall process of port and naval strategy is revealed by highlighting Nissan’s port and maritime strategy. It is observed that Nissan is dealing with several countries by importing and exporting different models (Lam, 2012). Therefore, the company has a complex port and marine system. In this report, the discussion is mainly about the port and maritime strategy for the Titan model of Nissan in the US and Europe.

4.2 Transport perspective:

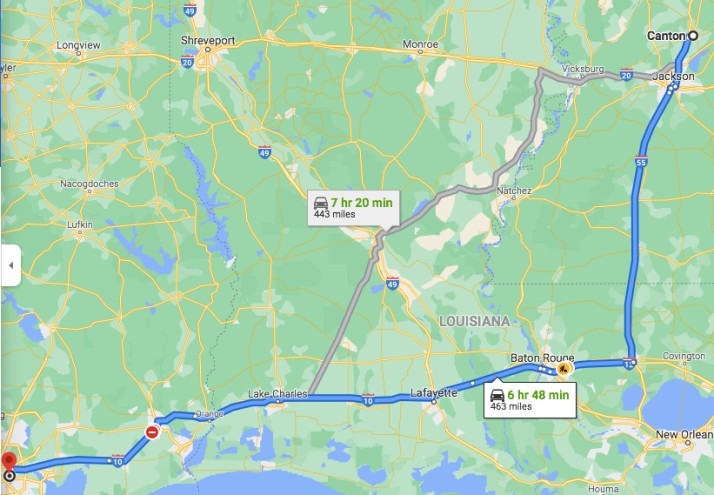

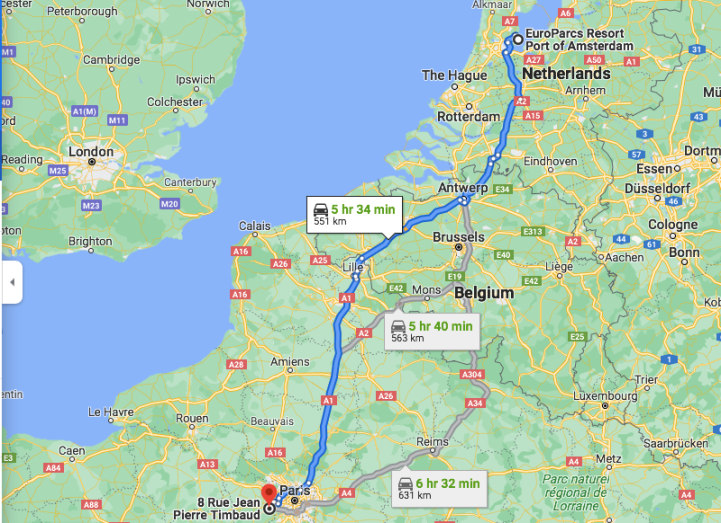

Nissan is manufacturing different models in different countries according to the customer’s demand and availability of resources. In this report, the discussion is mainly about Nissan’s Titan model, a good truck with a high-power engine and assembled in Canton, Mississippi. The machine is also made in the US, but the diesel engine is imported from Tennessee. The company is exported the Titan trucks into different countries, including Europe, Japan, and India. There is a complete process for exporting the vehicles to the targeted country (Rugman, 2005). In this report, the exportation of Titan in Europe. Firstly, the company uses trucks and big containers to export Titan from the assembling point to the port of Huston. The company is using the port of Huston for the exportation of vehicles from the US to the host country. Meanwhile, the company’s target is Europe, so there is a distribution point present in Paris. The company uses the world spirit ships for the shipment services from Huston to Amsterdam. The port of Amsterdam is considered to be the home port of the company in Europe. After importing the product at the port of Amsterdam, the company again uses the trucks and containers to supply the products from the port to the distribution point. The distribution point of the company is present at 8 Rue Jean Pierre Timbaud, 78180 Montigny-Le-Bretonneux, France. It is the overall route used by the company to export the outcomes into Europe. Meanwhile, the company is also focused on the protection due to which the vehicles are packed in containers. Firstly, the containers are loaded on ships that have a considerable capacity (Rugman, 2005). Meanwhile, the same containers are loaded on the trucks and exported to the distribution point. There is an essential process that the company has to follow by the company, due to which the company requires 16-20 weeks to provide the delivery. The following is the route detail for the exportation of the Titan from the US to Europe:

4.3 From assembling point to the port:

Figure 1: Canton, Mississippi to the port of Huston

From imported port to selected distribution point:

Figure 2: From the port of Amsterdam to Timbaud

4.4 Shipment perspective

The company has to deal with several customers for providing the services in Europe. Meanwhile, the company has to follow a long shipment route for the shipment of vehicles in France. Therefore, there are about 16 to 20 weeks required for delivering the products to the people. Firstly, the company required one to two days to place the production order (Sako, 2004). The next phase is the production that is required 14-17 weeks. The last phase is the delivery that is needed for 2-3 weeks. The following are the steps according to which the company completes the order:

| Steps | Leading time |

| Customer’s order | – |

| Placement of production order | 1-2 days |

| Production | 14-17 weeks |

| Shipment services | 2-3 weeks |

It is observed that there is a difference of four weeks between a minimum and maximum lead time. In this way, the people desire to complete the order in minimum time, but the company requires appropriate time to complete the production. The fundamental reason for increasing the lead time is the customization options given by the company to the customers. The company is following the ATO process strategy, according to which the customers can make specific changes in the vehicles according to their desires. Therefore, the company has to make the product according to the customer’s order rather than completely following the MTS model (Sako, 2004). There is also a specific need for the MTS process, but the company is mainly focused on the ATO model, due to which this lead time is fit for the company.

There is a long route that has to follow by the company for the exportation of products. There is approximately USD 750 required by the company for the shipment of every single vehicle. Meanwhile, there is also an issue of buffer capacity for the storage of final products. It is found that the company is following the ATO model, due to which the continuous production without customer’s order is not helpful for the company (Takeuchi, 2012). Meanwhile, there is a considerable buffer capacity required for the storage of vehicles. Therefore, the company manufactures the products according to the customer’s demand and regulates the business even with the limited buffer capacity (Takeuchi, 2012). The direction of the customers is high, so the company is continuously manufacturing and continuously supplying the products to the distribution points for the fulfilment of orders.

4.5 Selection of the deep-sea port:

The company deals with different types of vehicles, including cars and trucks. Therefore, the company is focused on the high-capacity ports that are beneficial for continuous imports and export services. Meanwhile, the company also has manufacturing plants in different countries, so selecting a deep seaport is essential for assembling the products. The company is also dealing with Asia pacific regions, including India, where the company used the port of Chennai for importation and exportation (Wiegmans, 2008). Meanwhile, the capacity of the port of Chennai is reduced, due to which the company terminated the contract with the port of Chennai. In short, the ability for importation and exportation matters a lot for the company.

Currently, there is a discussion about the Titan model of Nissan assembled in the US, so there is a need to reveal the options of ports for the company in the US. Several deep-sea ports are present in the US, including Port of South Louisiana, Port of Huston, and Port of Beaumont (Wiegmans, 2008). The company has to focus on related factors for the selection of deep seaports. The following is the criteria for the selection of ports:

- The capacity of the ports

- Shipment contracts and services

- Availability of hinterland connections

- Infrastructure and Working hours

- Legislative processes

The port of Huston is appropriate according to the selection criteria of the ports. It is why the company is using the port of Amsterdam for importation and exportation services in the US.

5. Risk/problem selection:

5.1 Risk to the company:

The company has the risk of a financial crisis because of complex supply chain management and currency exchange of the international level for dealing with local employees.

5.2 Detail of risks and their impact on total supply chain management:

Supply chain management is essential for supplying products on an international level. As the company is dealing with more than 132 countries, the supply chain is complex, due to which the possibility of threats is also increased. The company has to make contracts with local bodies and staff for supplying the products to local dealers. It is why the company has to deal in different currencies that may become the reason for the financial crisis by the company. It is also affected the supply chain of the company because of economic stability. The complex supply chain is also associated with the threat of wasteful spending that may become the reason for financial instability (Killing, 2013). In short, the continuity of the supply chain is challenging during the financial crisis, due to which the company has to mitigate the risk.

5.3 Risk positioning:

The risk is differently impacting the supply chain management and related operational management aspects of the company. Therefore, risk positioning is essential for mitigating the risks. The following risk matrix highlights the position of risk:

| Probability | Harm severity | |||

| Negligible | Marginal | Critical | Catastrophic | |

| Certain | Check and balance | |||

| Likely | Dealing with local dealers | |||

| Possible | Currency exchange | |||

| Unlikely | Local staffing | |||

| Rare | Management of supply chain | |||

5.4 Problem statement and research objectives:

The financial crisis is occurred because of complex supply chain management, and the regulation of supply chain management is impossible because of economic crisis, so the mitigation of risks is essential for the continuity of supply chain management efficiently.

The research aims to highlight the risks and threats of supply chain management and its impact on its operation management and progress. Meanwhile, the study also seeks to make the solutions, so it becomes helpful for the company to mitigate the financial risks for the supply chain management (Herciu, 2013).

• Main research question:

Why does the company face a financial crisis because of complex supply chain management?

• Theoretical research question:

How does the company manage the financial crisis to enhance the efficiency of supply chain management?

How can the company continue the supply chain management under the financial crisis?

6. Findings and analysis:

The problem is the financial crisis because of the complex supply chain management. The company’s supply chain management and several related processes are highly influenced because of the financial crisis faced by the company. The company is critically focused on the problem and has a plan to mitigate the risk. Therefore, the following processes and information are beneficial to minimize the risks and continue the supply chain and operation management better.

6.1 Risk drivers:

The company has a complex supply chain on an international level for supplying the products to different countries. Therefore, the company has to focus on the related factors and components for supply chain management efficiency. It includes the suppliers, transportation, and related physical resources. All of these components required money for the sake of working according to the company’s objectives. It becomes easy for the company to deal with international currency globally (Xia, 2011). Still, the company also has to use the local currency for local employees and resources, which is the company’s problem. In short, converting international currency into local currency is a significant challenge for the company to manage the financial aspect of supply chain management. It is why the company is facing a substantial economic crisis because of the complex supply chain management. Nevertheless, the company continuously supplies the vehicles even with the substantial financial problem (Toma, 2013). Still, there is a need to fixate the economy for the sake of the company’s rapid growth. It is found that the conversion of international currency into local currency is the crucial risk driver for producing significant threats related to economic stability and continuity of supply chain management.

6.3 Case studies:

Several studies revealed that the association of supply chain management and financial stability is essential for the company’s progress. If the company wants to continue the supply chain without any external threat, financial management is compulsory. There are two aspects directly associated with supply chain management, including the economic problems because of supply chain management and management of supply chain during the financial crisis—both of these problematic situations faced by Nissan due to which the supply chain is highly disturbed. Initially, the financial state is disturbed because of supply chain management (Kuei, 2001). Nowadays, the company continues the supply chain even with the financial crisis, but it is essential for its operation management.

According to a Thailand case study, supply chain risk management is the only way to continue the company’s operation management. The supply chain is influenced by several risks, including management risks, supplier risks, transportation risks, and financial risks. All risks can quickly be mitigated with planning and management of resources, but the company does not manage the financial stakes efficiently. It is an alarming situation for the company because the economic crisis directly impacts increasing the prices of the products (Raka, 2015). The variation in the merits of the same products in different countries is also occurred because of the financial crisis in supply chain management. Therefore, the companies have to mitigate the financial risks.

A case study is analyzed about the continuity of the supply chain even with the financial crisis. It is found that the companies may face a financial crisis because of supply chain management then there is no need to discontinue the supply chain management but have to change the priorities. Firstly, the company has to adopt the lean management strategy to overcome wasteful spending. Meanwhile, the company has to adopt advanced technology to keenly monitor the regulation of supply chain management (Blome, 2011). Therefore, the company can regulate the business environment along with the management of risks.

6.4 Management of risks:

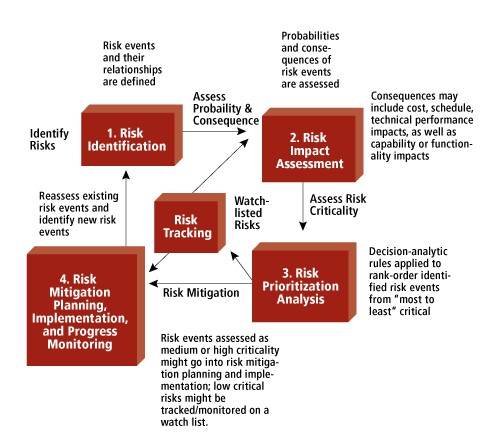

When the company is struggling because of a particular risk, it has to plan to manage risk. It is not easy for the company to mitigate the risk immediately but follow a specific process. The first step of the risk mitigation framework is the risk identification process. Nissan is struggling because of a severe financial crisis, due to which there is a need to identify the reasons for the financial crisis. The second step is the risk impact assessment, in which the impact of risks is determined (Ghadge, 2012). It is analyzed that the financial crisis is harmful to supply chain management and directly affects the company’s production and progress. The third step is risk prioritization analysis, according to which the company classified the risks into different sections. After the classification of risks, the company has to analyze each risk and mitigate the risk according to the company’s needs. The last process is risk mitigation planning according to the analysis of the risks. When the company analyses the risks, it becomes easy for the company to mitigate risks (Ghadge, 2012). It is compulsory for the company to continuously monitor the whole risk mitigation process for producing long-lasting consequences for the risk mitigation process. The following figure highlights the risk mitigation process:

6.5 Best mitigation option for the company:

The risk tracking process is the best risk mitigation option for the company. It is observed that the companies are primarily identified the risks and plans to mitigate the risks. Still, these plans do not produce long-term consequences because of a lack of risk tracking, which is the company’s primary challenge (Blackhurst, 2008). The company has to track the risk for overcoming the entire related hurdles from supply chain management. The company can adopt digital processes for risk tracking processes. The best way of risk tracking process is the association of risk tracking process with risk management strategy. When the company makes the risk management strategy, the company has to make a monitoring process to identify and manage risks (Blackhurst, 2008). It is also helpful for the preplanning of the dangers and helps to overcome the severity of threats.

6.6 Impact of solution for the total supply chain:

The mitigation of the risks is helpful for the management of economic status and the regulation of the supply chain management. It is observed that the company can quickly make progress because of the control of financial position and overcome the related risks. Suppose the company faces risks related to financial management (Schmidt, 2013). It is harmful to supply chain management and considered challenging for the overall operational processes. The company has to manage the risks related to the financial stability and continuity of supply chain management. Nissan has analyzed these risks and plans for the evaluation of financial troubles (Schmidt, 2013). The company also plans to fixate the financial risks by making specific changes in supply chain management monitoring.

7. Conclusion and recommendations:

7.1 The answer to a research question:

The research questions are based on the management of financial risks that are influencing supply chain management. The following are the answers to supply chain management:

• MRQ:

The company has to make the supply chain management for supplying the products on an international level. When the company has to make supply chain management, it must consider the related factors keenly, including financial management, local dealing, local staffing, and legislative process. The company can’t find any hurdle by focusing on these factors. Meanwhile, when the company is compromising on any single factor, it faces related risks (Veloso, 2002). Meanwhile, when the company compromises on check and balance and related financial associations, it faces a severe financial crisis that is also challenging for the continuity of supply chain management.

• Q:

The company must manage the financial crisis for the continuity of supply chain management. Firstly, the company has to identify and evaluate the risk and threats related to supply chain management. After analyzing the risks, the company has to make the risk management strategy according to the mitigation of possible risks (GALCIUC, 2009). Meanwhile, the company has to make a monitoring policy for the risk, making it easy to manage risks continuously.

Unfortunately, if Nissan faces a financial crisis, there is no need to terminate the supply chain management because it may create problems for the overall operational management process. In this way, the company has to make a lean management strategy to manage wasteful spending that is helpful for economic stability. Meanwhile, the company has to strengthen the monitoring policy, making it easy to identify and evaluate the risks. Nissan is also struggling because of the financial crisis (Blome, 2011). It is also adopted these strategies due to which it becomes possible to regulate the business environment even in the financial crisis.

7.2 Recommendation and implementation plan to reduce the risk:

It is recommended that the companies make a risk management strategy by explicitly focusing on the risk monitoring process. The stronger the risk policy, the more chances to manage the risk without influencing the supply chain management. The company also has to use the digital process to monitor the supply chain because it is the best way to manage it (Hillson, 2002). Meanwhile, the company also has to implement the lean management policy for the management of wasteful spending. It is not easy to implement the lean management strategy but also focuses on managing inventory and stock.

7.3 Integrate the recommendation into the supply chain:

The possible solution to the financial risks for Nissan is provided in the above section. It is found that the supply chain is highly influenced because of the financial crisis, so the solution and recommendations must be integrated with the supply chain management. Therefore, the company has to digitalize the supply chain management to improve the monitoring process (Foster, 2010). Meanwhile, there is also a need to improve the risk management strategy, specifically for financial management. In the end, the company should have to make a critical eye on revenue management.

8. References:

Blackhurst, J. V., Scheibe, K. P., & Johnson, D. J. (2008). Supplier risk assessment and monitoring for the automotive industry. International journal of physical distribution & logistics management.

Blome, C., & Schoenherr, T. (2011, November). Supply chain risk management in financial crises–A multiple case-study approaches. Research gate. Retrieved October 23, 2021, from https://www.researchgate.net/publication/227420847_Supply_chain_risk_management

_in_financial_crises–A_multiple_case-study_approach.

Blome, C., & Schoenherr, T. (2011). Supply chain risk management in financial crises—A multiple case-study approaches. International journal of production economics, 134(1), 43-57.

Cariou, P., Ferrari, C., & Parola, F. (2015). Strategies in maritime and port logistics. Maritime Economics & Logistics, 17(1), 1-8.

Chen, Y. S., Su, H. C., & Ro, Y. K. (2017). The co-evolution of supplier relationship quality and product quality in the US auto industry: A cultural perspective. International journal of production economics, 184, 245-255.

Foster, A. D., & Rosenzweig, M. R. (2010). Microeconomics of technology adoption. Annu. Rev. Econ., 2(1), 395-424.

GALCIUC, V., & OJOG, A. (2009). The aspects of the development of the automotive industry in connection with the world financial crisis.

Ghadge, A., Dani, S., & Kalawsky, R. (2012). Supply chain risk management: present and future scope. The international journal of logistics management.

Herciu, M., & Ogrean, C. (2013). Financial Risks–A Case Study for Automotive Industry. Studies in Business & Economics, 8, 50-55.

Hillson, D. (2002). Extending the risk process to manage opportunities. International Journal of project management, 20(3), 235-240.

Jindal, D., Jee, C., & Thakur, R. R. (2011). Nissan: go‐global strategy. Business Strategy Series.

Killing, P. (2013). Strategies for joint venture success (RLE international business). Routledge.

Kuei, C. H., Madu, C. N., & Lin, C. (2001). The relationship between supply chain quality management practices and organizational performance. International Journal of Quality & Reliability Management.

Lam, J. S. L. (2012). Risk management in maritime logistics and supply chains. In Maritime Logistics. Emerald Group Publishing Limited.

Plakoyiannaki, E., & Saren, M. (2006). Time and the customer relationship management process: conceptual and methodological insights. Journal of Business & Industrial Marketing.

Puvanasvaran, A. P., Muhamad, M. R., Megat, M. H. M. A., Tang, S. H., & Hamouda, A. M. S. (2008). A review of problem-solving capabilities in lean process management.

Raka, C., & Liangrokapart, J. (2015, January 1). Supply Chain Risk Management: A case study in Thailand. EconStor. Retrieved October 23, 2021, from https://www.econstor.eu/handle/10419/209269.

Rugman, A. M. (2005). The regional multinationals: MNEs and global strategic management. Cambridge University Press.

Sako, M. (2004). Supplier development at Honda, Nissan and Toyota: comparative case studies of organizational capability enhancement. Industrial and corporate change, 13(2), 281-308.

Schmidt, W., & Simchi-Levi, D. (2013). Nissan Motor Company Ltd.: Building Operational Resiliency.

Stone, G., Miemczyk, J., Howard, M., Graves, A., & Esser, R. (2006). Establishing build to order in the European automotive sector. IFAC Proceedings Volumes, 39(3), 291-296.

Takeuchi, A. (2012). Nissan motor company. The Corporate Firm in a Changing World Economy: Case Studies in the Geography of Enterprise, 36, 166.

Toma, S. G., & Marinescu, P. (2013). Global strategy: the case of Nissan Motor Company. Procedia Economics and Finance, 6, 418-423.

Veloso, F., & Kumar, R. (2002). The automotive supply chain: Global trends and Asian perspectives.

Wiegmans, B. W., Hoest, A. V. D., & Notteboom, T. E. (2008). Port and terminal selection by deep-sea container operators. Maritime Policy & Management, 35(6), 517-534.

Witcher, B. J., Chau, V. S., & Harding, P. (2008). Dynamic capabilities: top executive audits and hoshin kanri at Nissan South Africa. International Journal of Operations & Production Management.

Xia, Y., & Tang, T. L. P. (2011). Sustainability in supply chain management: suggestions for the auto industry. Management Decision.

write

write