A company’s success and competitive advantages in a globalized economy depend greatly on its global supply chain design. The world is intertwining and getting smaller with the advent of increased globalization. Companies spread to various geographical areas, creating complicated and advanced logistic frameworks. Companies should implement an efficient supply chain design to cope with the dynamic nature of the markets and fulfill customers’ expectations. This study will review some views on global supply chain design and mention things a company must consider while creating its design. It will indicate typical problems of global supply chain design and possible forthcoming challenges.

Determining the Optimal Supply Chain Design

To design an efficient supply chain, a company must define its goals and objectives. Meixell and Gargeya (2000) observed that global supply chain design may contribute significantly to enabling companies to accomplish various purposes, including decreasing costs, enhancing customer services, and achieving competitive advantage(Meixell & Gargeya, 2005). A company’s supply chain design should be based on its product portfolio, customer demands, and competitor positioning. However, it is also important to thoroughly appraise demand and supply patterns to optimize the supply chain design. Therefore, companies need to understand the complexity of changes in demand patterns. This helps determine the adequate levels of stockholding that should be applied in addition to giving way forward in selecting the best methods of transport for meeting a variety of customers’ requirements. It enables companies to evaluate supply patterns and identify possible threats that should be overcome for companies to do so effectively. By studying the complexity of the supply and demand side of the business, companies will achieve firmness and give in to their supply structure, which is dynamic.

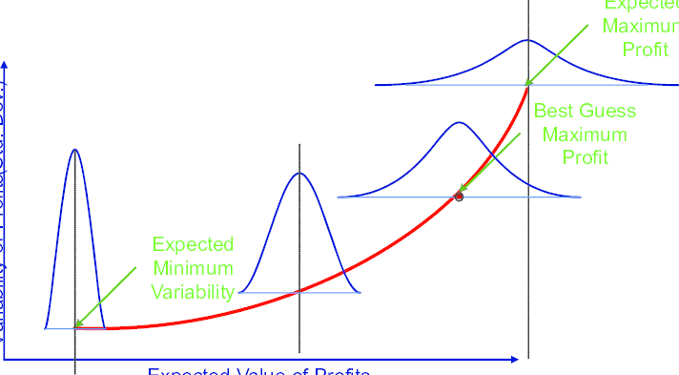

Organizations ought to factor in the cost elements surrounding procurement, transport, warehousing, and storage in the respective supply chains. A well-structured supply chain needs to reduce these costs while meeting the market needs at the same time. For instance, there is a chance to use the consolidation procedure of accumulating small deliveries into bigger ones with the eventual decrease in delivery cost. There is a need to innovate technology, such as improving the visibility of supply chains and smoothing operational flows (The Risk Curve of Supply Chain Configurations 2013). Modern inventory management is based upon contemporary intelligence technology that tracks and analyzes inventories, which allows the prediction of processes and, thus, better Management. A company should also consider investing in a modernized warehouse management system for higher storage capacity, reduced carrying costs, and enhanced efficiency.

Resilient supply chains must include effective supplier management. Frequent communication with partners helps one secure favorable negotiation terms and timely deliveries that go a long way in boosting the overall efficiency of supply chains. Therefore, such a proactive engagement of an organization makes it more flexible to fit any changes taking place in the market environment. It would be important to develop an understanding amongst companies that designing a good supply chain could be key to achieving sustainable development (Global et al. Management, 2022). With increased focus on matters of concern about the environment and society, the SCM decision should be embedded with the spirit of the CSR network. The switch to sustainable packaging, low carbon footprints, and working with responsible suppliers also comes into play. The advantages of adopting such initiatives go beyond the conservation of the environment. Sustainable practices incorporated into the supply chain design improve the company’s image and reputation. Through adherence to ethics and advocating for eco-friendly decisions, businesses can create favorable perceptions among consumers and shareholders. This makes a reputable organization and improves its image in the market.

Factors to Consider In Global Supply Chain Design

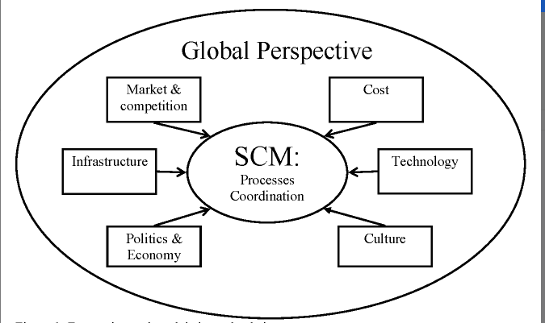

When companies design their global supply chain, there are several important considerations. These variations are also influenced by the different regions’ cultural and linguistic aspects of the environment. There is a need for such companies to understand cultural variances appropriately and devise ways of communicating across borders to avoid such conflicts. Companies, particularly in dealing with regulatory and compliance issues of particular countries, have their peculiar difficulties. The efficiency of supply chains may be affected by these laws and regulations. Such rules and regulations can influence the transport processes, product packaging, importations, and exportation procedures (Meixell & Gargeya, 2005). In a literature review by Meixell Gargeya (2005), several factors are suggested for use in the global supply chain design. As noted in their critique, one important aspect is transport. The company should consider the transporting mode and infrastructure when they design their supply chain transportation research. It emphasizes the importance of good and effective supply chains in creating global ones.

Suitable transportation modes are an important part of global supply chain design. When choosing the best mode of transport, companies ought to consider factors like distance, costs, customs regulations, and time. Likewise, air transport can be quite expensive but takes a shorter time, while sea transport is cheaper but longer. Chu et al. (2020) also note that these factors should be considered regional. This is apparent in how they use text mining to uncover area-based issues, and therefore, companies need to modify and design their supply chains according to various regional challenges (Chu et al., 2020). This confirms that supply chain design requires a granular and region-specific approach.

Companies must be cautious about choosing suppliers and partners in their supply networks. Companies are increasingly outsourcing and offshoring their activities, leading to wider supplier bases on a global scale (Meixell & Gargeya, 2005). This, however, leads to increased vulnerability in the supply chain. As such, ensuring effective supplier selection to guarantee reliability, quality, and sustainability would be important. Both emphasize the need for a thorough literature review. Meixell and Gargeya (2005) noted that knowledge of past research is vital for effective supply chain management based on relevant decisions. Such a philosophy concurs with Chu et al.’s (2020) strategy based on the data mining method, implying that it is essential to remain one step ahead regarding evolving dangers and tendencies to adapt and enhance the supply chain design configuration constantly.

Common Problems and Issues in Global Supply Chain Design

Companies face different challenges when dealing with the global nature of supply chain networks. Such supply chains are often characterized by natural hazards such as earthquakes, volcanic eruptions, floods, and the like; political instability in the form of wars and invasions, strikes, and civil and other such cases as demonstrated by the COVID-19 pandemic (Ivanov, 2020). Such disruptions may lead to late deliveries, increased costs, and even unhappy customers. Therefore, companies must develop contingency strategies to address these interruptions successfully (Ivanov, 2020). Looking at recurring issues in global supply-chain design is imperative because it explains why firms encounter difficulties. The literature review by Meixell and Gargeya (2005) pinpoints some perennial problems related to online instructional practices. Multiple factors make decision-making extremely complex, one of these issues being the complexity of decisions. However, global supply chain design is very complicated because it involves many aspects like transportation pathways, geographical areas, and ever-evolving risks, thus bringing tough management decisions into play.

This lack of visibility and control has become critical in almost every global supply chain design area. Effective monitoring and tracking of continuous supply chain flows is difficult because one has to manage the complexities of dealing with many suppliers that provide different forms of transportation, like ships, trucks, and railway systems. However, this complexity commonly leads to negative repercussions such as stock losses, unforeseen predictions, and operational congestion. Organizations can address this complex problem using sophisticated supply chain management software and sturdy traceability programs.

This research is greatly expanded upon by Chu, Park, and Kremer (2020), who provide some insight into regional-specific risks (Chu et al., 2020). Clarify that implementing such a policy would face resistance. Companies need to be able to locate and manage geographical threat factors of an efficient and sustainable global supply system. More visibility and control must be addressed in optimizing the global supply chain (Chu et al., 2020). Advanced technology integration becomes a prerequisite. The emphasis placed by Chu et al. on the need to consider a multidimensional perspective on supply chain design responsiveness to regional risk is still relevant. Inventory is also complicated because it entails managing a complex chain that spreads beyond national borders. These include demand prediction errors when the stock levels get blurred out, leading to an overstock situation whereby demand remains low, resulting either in a surplus backlog situation or a lockout where the market becomes unmet when the stock shortages arise. The company should expect higher operational expenses and high customer dissatisfaction in these circumstances.

Future Challenges in Global Supply Chain Design

The interconnected world makes global supply chain design more complex with different and growing demands. Striking a balance between global integration and localization presents one of the key challenges for companies. Although this approach reduces production costs, it needs to consider the particular requirements of regional clients. However, customizing products and processes to suit local demands could add costs and compromise efficiency (Meixell & Gargeya, 2005). Organizations must adopt a supply chain design responsive to regional requirements but retain the advantages of global linkage. In a volatile business world, we must proactively foresee the upcoming challenges of worldwide supply chain design (Marker, 2017). A good starting point is the literature review by Meixell and Gargeya (2005), which can help determine possible obstacles in the future. An example of a challenge could be the enhanced incorporation of digitized applications into the process, which might induce additional nuances or possibilities for enhancement during the designing stage.

Chu et al.(2020) propose that text mining is a means of risk identification, thus implying an increasing input by data analytics and artificial intelligence into supply chain design in the future(Chu et al. 2020). Firms may be required to shift to a data-oriented approach in decision-making, including incorporating various technological innovations, to remain at the edge of new perils and improve their business processes constantly. The other anticipated future problem is the rising process that leads to the increased digitization and automation of supply chain processes. Utilizing technologies like artificial intelligence (AI) helps improve the operations related to the supply chain by making it quicker, more effective, and less risky for errors associated with humans. It implies that firms must undertake technological renovations and educate their workers to accommodate such adjustments.

The design of a global supply chain is a key area that businesses need to consider to realize their objectives and keep them relevant in the international market. Companies should consider their goals, demand-supply pattern, cost, and sustainability for determining the best supply chain design. A global supply chain must consider factors like culture, regulation, and transport: companies must know how to respond to prevalent and recurring issues, like supply chain breakdowns, low visibility, and stock control. Firms should be adaptive and evaluate the supply chains’ design as the market and customers’ dynamics change.

References

Chu, C.-Y., Park, K., & Kremer, G. E. (2020). A global supply chain risk management framework: An application of text-mining to identify region-specific supply chain risks. Advanced Engineering Informatics, 45, 101053. https://doi.org/10.1016/j.aei.2020.101053

Global Operations and Supply Chain Management (2022). Fresh Essays Samples. https://samples.freshessays.com/global-operations-and-supply-chain-management.html

Ivanov, D. (2020). Predicting the impacts of epidemic outbreaks on global supply chains: A simulation-based analysis on the coronavirus outbreak (COVID-19/SARS-CoV-2) case. Transportation Research Part E: Logistics and Transportation Review, p. 136, 101922–101922. https://doi.org/10.1016/j.tre.2020.101922

Marker, A. (2017). 50 Educational Resources in Global Supply Chain Management | Smart sheet. Smart sheet. https://www.smartsheet.com/top-global-supply-chain-management-training

Meixell, M. J., & Gargeya, V. B. (2005). Global supply chain design: A literature review and critique. Transportation Research Part E: Logistics and Transportation Review, 41(6), 531–550. https://doi.org/10.1016/j.tre.2005.06.003

Meixell, M. J., & Gargeya, V. B. (2005). Global supply chain design: A literature review and critique. Transportation Research Part E: Logistics and Transportation Review, 41(6), 531–550. https://doi.org/10.1016/j.tre.2005.06.003

The Risk Curve of Supply Chain Configurations (2013). Research Gate: Research Gate. https://www.researchgate.net/figure/The-Risk-Curve-of-Supply-Chain-Configurations-Reprinted-from-Robust-Global-Supply_fig1_257719817

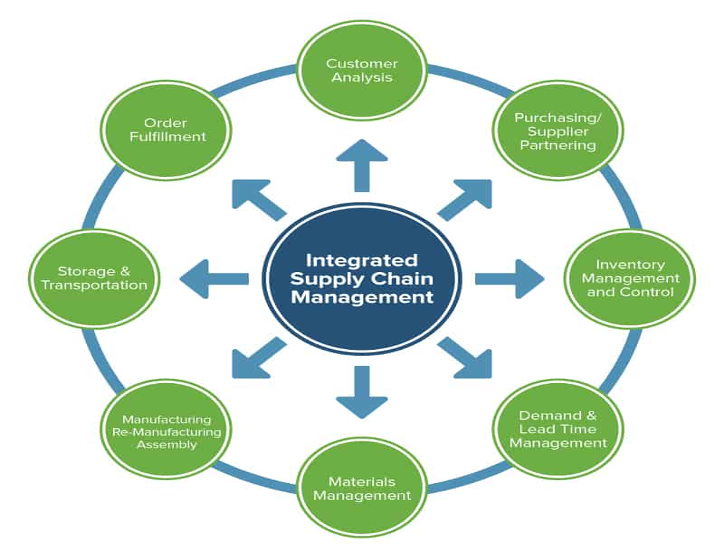

The Diagram Below Depicts the Global Supply Chain Management Smart Sheet.

The Risk Curve of Supply Chain Configurations

The Diagram Below Depicts Elements In The Supply Chain in the SCM Network.

write

write