Introduction

The next area is shoe manufacturing. It has become one of the growing and leading industries in the world, so billions require it worldwide. All categories of shoes are produced, including formal, casual, athletic, unique design, etc. That is why many materials, styles, and diverse processes characterize the manufacturing of this Industry to meet the demands laid by fashionable and sporty customers.

Manufacturers of shoes can be small, traditional artisans and big transnational corporations. The most successful companies in this business usually have very extended supply chains, obtaining raw materials from different areas and selling finished products to various global markets. The dynamism involved in the Industry often concerns changing fashion ideas and technologies and more focus on sustainability and corporate social responsibility.

From this size and scale, a shoe manufacturing company would gain some impetus in production capacity, market reach, and innovation possibility. Therefore, large-scale manufacturers would be invested in research and development with advanced technologies dealing with design features’ capacities or abilities, the production benefits, and even the supply chain management efficiency. Small-scale shoe manufacturers may concentrate or focus more on particular niche markets, complementing the designs’ fine craft and original elements.

There are impressive changes in the history of the last few years that reflect the trends of the shoe manufacturing industry, being adopted standards for operating with environmental materials and socially proven labor policies to stringent regulations on how waste should be minimized, according to increasing consumer preference for green products. Remarkable in this development is how 3D printing has given a new dimension to shoe production.

Hayes and Wheelwright Strategy Framework:

Applying Hayes and Wheelwright’s strategy framework to the shoe manufacturing industry in India would present a perspective concerning process innovation, flexibility, and market orientation.

In the context of process innovation, many shoe manufacturers in India have taken up modern technologies and modes of production. As larger firms invest in greater automation of the cutting, stitching, and molding processes, they invest in more significant gains in precision and efficiency. Smaller producers might retain their relative advantage in artisanal methods marked by craftsmanship and unique trademark designs. The Industry balances existing traditional craftsmanship with technological innovations in the interface of traditional and modern technology.

The Indian shoe manufacturing sector portrays flexibility because it has produced an abundant variety of end products. Variation in footwear design could be seen through traditional and contemporary items, whilst the ability to sell both at home and abroad demonstrates flexibility. How production methods can be changed to reflect new consumer needs and market requirements represents some level of flexibility in this sphere.

Concerning market orientation, Indian shoe manufacturers are global in their outlook. Most of their produce is exported; hence, it reflects immense knowledge of international market trends and the needs of the customers. At the industry level, this global orientation should match a commitment to quality, diversity in designs, and service that meets international standards.

Assessing Operations Performance using 4Vs and 5KPIs:

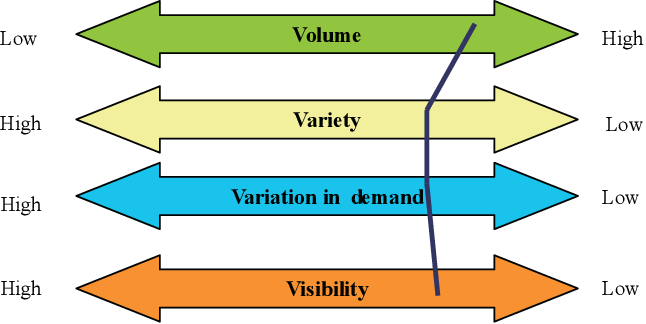

4Vs of an Indian-based shoe manufacturing firm are analyzed based on characteristics and are stated as follows:

Volume:

High Volume: The market condition of the volume order for an Indian-based shoe manufacturing company in India generally stays on the higher side because, in every festive season or new trend of fashion in footwear, including sports shoes, there normally resides an enormous order appeal. Therefore, when discussing such large organizations, their strutheirres may engaelves in buo enhance the finer pace of production.

Variety:

Wide variety- The Industry shows a variety of products and offers many styles, materials, and designs. To fill an order, one has to cover a vast range of footwear- from the traditional hand-stitched footwear to modern trendy athletic pair of shoes.

Variation:

The modest variations are related to seasonal trends, changing consumer preferences, and demand fluctuations in the order fulfillment process. Manufacturers need to be flexible enough for such variations associated with the quantity and specifications to manufacture goods, followed by variations in production schedules.

Visibility:

Varied Visibility: It depends upon the level of integration with your supply chain and even the size. More giant manufacturers will tend to hold better visibility enabled with advanced systems related to tracking and real-time monitoring for speed toward openness—from the placement of the order to delivery. Smaller manufacturers might take on the older conventional tracking methods, so their visibility will not be as plain.

Figure 1: Graph showing operations performance according to the 4Vs

(Source adapted from Kohli et al., 2020)

Assessing Operations Performance of 5KPIs

Cost

Pros: The Indian shoe manufacturing business gets the advantages of low cost and availability of raw materials. However, slight alterations in transportation charges as well as energy may be noticed while it carries the total cost of the order fulfillment processes to the customers’ satisfaction.

How to Improve: It is essential that there be a guarantee for the adoption of cost-saving technologies that will ensure that its supply logistics are perfected for maximum savings on cost.

Quality

Positives: It is an industry synonymous with core expertise and quality orientation. Various quality control measures can be integrated within the production process, with the finished product being at par or better than international standards.

How to improve: Though there may not be many negatives, continued investment in maintaining quality standards, along with the implementation of Six Sigma or equivalent methodologies and employee training, shall help even more in product improvement.

Speed:

Merits: In the case of the shoe manufacturing sector, order fulfillment is comparatively prompt, especially for bulk orders. Huge-size manufacturers usually have an automated process and receive the required item promptly.

De-merits: If the internal processes are further streamlined and fine-tuning of inventory is done, then promptness in receiving the items can be achieved with the induction of new manufacturing technologies.

Dependability:

Positive Points: A number of shoe manufacturers exist in India, which might have a reliable and dependable supply chain from suppliers and distributors. Dependability is usually high since supply chains are usually accurate.

Points of Improvement: Dependability might be improved by formulating a better system of communication regarding the suppliers, better forecasting of demand, and developing such contingency plans for dealing with any uncertainty.

Flexibility:

Positive Points: The industry is flexible enough because shoes of a good variety are typically manufactured to suit a number of different kinds of consumers. It is broad regarding volume, variety, and occasionally mixture flexibility, including postponement.

Areas of Improvement: A more flexible line in its manufacturing processes would greatly assist in making rapid changes according to market necessities. This flexibility can be augmented with investments in technology that enable product diversity.

Summing up, one may say that the shoe manufacturing industry in India has been able to perform positively about the five KPIs; however, there is to be room for improvement. Continuous techno-investment and process optimization, on the other hand, will significantly strengthen one’s capabilities of order fulfillment, therefore providing sustained competitiveness in the global market.

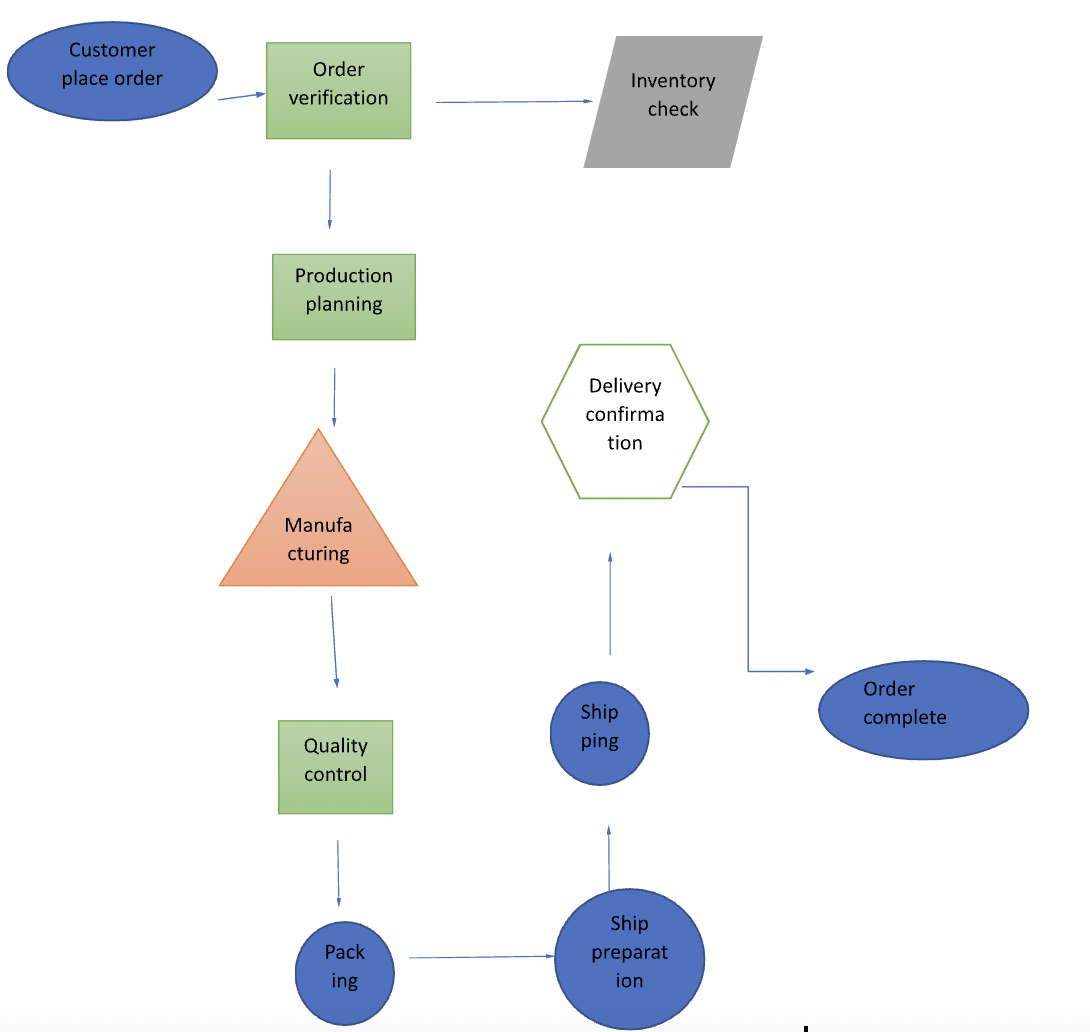

Detailed Process Map: Order Fulfillment Process in Shoe Manufacturing

Order Placed by the Customer: A customer places an order through the company’s website website, retail shops, or authorized distributors. The customer then confirms the shoe’s particular model, size, and quantity from the seller.

Verification of Orders:

The details of the order and its intricacies are carefully verified to determine product details required to be recorded. After the verification process, companies directly inform customers about any discrepancy.

Inventory Check

Explanation: This step involves an inventory check on the availability of the models and sizes of shoes that have already been verified for orders. If checked items are available in stock, further processing continues; otherwise, a backorder or some other alternative to these orders is made.

Production Planning

Explanation: A production planning card should be generated for the details of the verified orders. In this case, available capacity, lead times, and resources for production should be accounted for. It ensures a logical order of activities, which leads the way for subsequent implementation.

Manufacturing

After that stage comes the natural manufacturing process, which entails stages such as cutting and sewing, assembly, and quality checks, these stages are supported by skilled workers and automatic machinery, producing production efficiency.

Quality Control:

Explanation: Finished shoes undergo stringent quality control checks so that they are maintained according to the specified standard of the organization. Any defect or deviation is handled correctly by doing rework or disposing of that product.

Packaging:

Explanation: After this is done, moving on to the packaging line, all the approved products from the production floor enter the packaging phase, where they are correctly packed and sealed. Protective measures, aesthetic presentation, and sustainable best packaging practices are observed in this stage.

Shipping Preparation:

For dispatch, Shoes are packed and then dispatched for the shipments. Required shipping labels of all products, coordination of logistics partners, and system updates indicating the dispatch status of the product.

Shipping:

Explanation: The products are sent to the customers using different shipping mechanisms and considered based on parameters such as speed, cost, and reliability so that customers can be happy.

Delivery Confirmation:

Description: After the delivery of the products to the customer is successfully made, accessible of malfunctioning, the status of that specific order in the system is updated to completion, and the customer is intimated about it. The customer may also be asked to provide feedback on how satisfied they were with the process.

Order Completion:

Description: The whole process of delivering the ordered products concludes. Requisite information, like the times when deliveries were done, the customer’s feedback, and the pitfalls faced by the executors, is recorded for analysis or future reference.

The following detailed process map will lay out the graphical representation of shoe manufacturing order fulfillment, focusing on the critical steps and decision points. Such a map is precious, a working tool for the organization’s analytical and communication reasons.

Figure 2: Flow chat. overall map for the current process

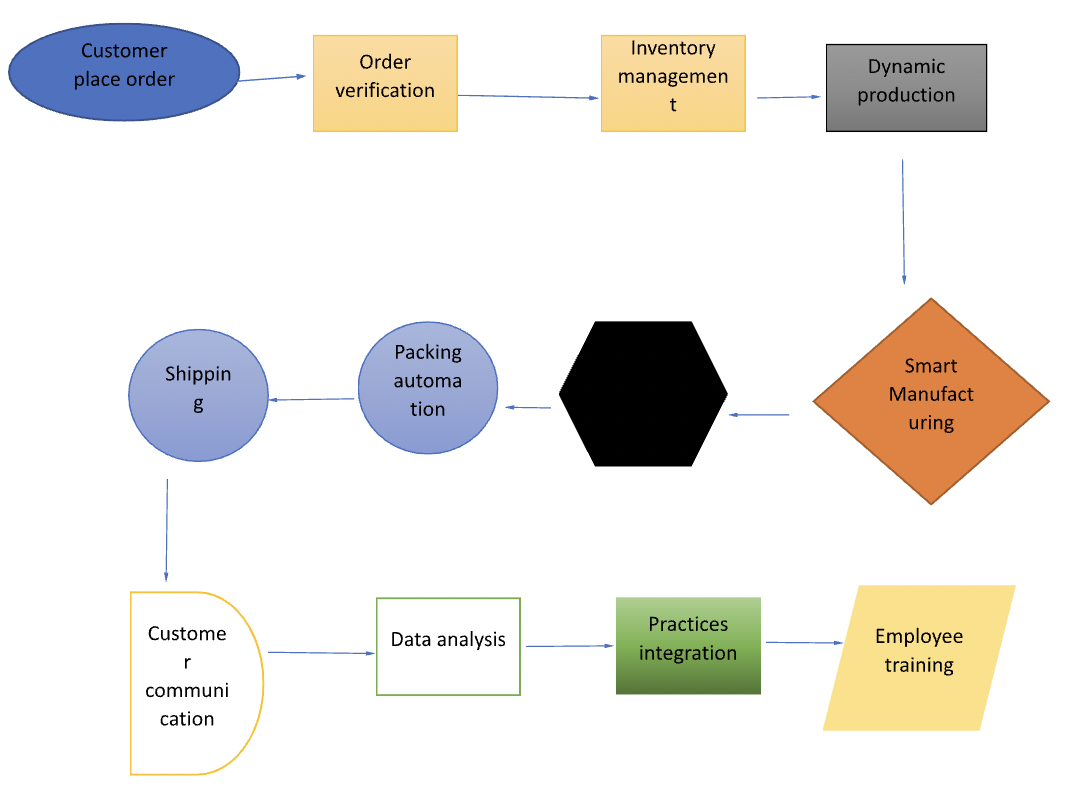

Analyzing and improving the current process

Customer Places Order:

Enhancement: The advanced online order management system with a user-friendly interface will have the capability to let customers customize their orders and track them in an easy way, thus making the system flexible for its users.

Order Verification:

Enhancement: The inclusion of automatic mechanisms for order verification will be a support through which errors in placing orders can be minimized, and therefore, authentic order placement can be done accurately.

Real-time Inventory Management:

Enhancement: Real-time inventory management is tracked by RFID technology and IoT devices, which suits users with a level of minimum stock-outs and error-free stock keeping.

Dynamic Production Planning:

Improvement: Use real-time input for demand, production capacity, process routing, and resource availability to carry out dynamic production planning algorithms that optimize scheduling and them lead times.

Smart Manufacturing:

Improvement: Include new advancements in smart manufacturing, such as internet of things -based machinery and robotics all cross-linked with each other. This will give better results and strengthen production, decrease faults, and increase mass customization on large scales.

Automated Quality Control:

Improvement: An automated quality control mechanism is to be maintained using AI-supported mechanical visual inspection systems that require minimal person-hours to check each product against a consistent quality level.

Automated Packaging:

Improvement: Utilize automatic processes in packaging the shoes with the aid of packaging material already set up based on the model type of shoes so that it becomes more efficient with less wastage, and optimization of the packaging process is not done at the cost of wasting person-hours.

Shippers.net:

Improvement: Integrate route optimization algorithms and real-time tracking to the existing shipping process to provide customers with accurate delivery estimates.

Customer Communication Platform:

Enhancement: Implement a customer communication platform from which the client can be shared in a timely manner if anything happens or eventuality has arisen, especially regarding order delay issues.

Data Analytics and Continuous Improvement:

Enhancement: Implement a data analytics tool to dig out insights from the entire order fulfillment process. Set up a team for continual improvement, which does analysis on data proactively recommends areas for further optimization.

Integration of Sustainable Practices

Enhancement: Every process shall integrate the sustainability practice, using eco-friendly products right from packing materials, achieving a target of waste reduction, and sourcing out from a vendor who has ethical concerns.

Training and Empowerment of Employees:

Enhancement: Make adequate budgetary provisions for implementing training development programs for the workforce towards adaptation and utilization of new technologies. This will also bring out their change-friendly behavior and exposure to skill enhancement for their work role.

This re-envisaged future state map presents a view of the shoe manufacturing Industry envisaged about this futuristic state, where highly advanced technologies are used throughout an agile, customer-centric order fulfillment process. Incorporating advanced technologies, coupled with real-time data analytics and green commitment, is envisaged to reshape the order fulfillment process for better efficiency. Therefore, it should enable supreme quality and great flexibility to all market demands.

Figure 3: Flow chart for the improved current process

Recommendations for the implementation of the process redesign.

The kind of change management strategies and a few challenges that are required for the implementation of the redesigned shoe manufacturing order fulfillment process require a strategic approach. Ensuring alignment from the top leadership, where the leaders champion a vision and goals within the organization to support the redesign. Cross-functional collaboration, communication, and understanding will be promoted by creating teams representing different departments involved in the process. Applying employees in the change will ensure success the Involvement of employees from the beginning should be done, seeking their input and addressing concerns to build a sense of ownership. Clear communication is paramount in the whole process, with a comprehensive plan outlining the change, reasons behind it, and expected benefits. The training program will be implemented to equip employees with the skills required for new technologies so that resistance is minimized and ensure ease in transition.

Identify change champions within the organization who inspire and motivate their peers through implementation. Run a pilot implementation in a controlled environment before full roll-out, thus allowing testing, refining, and the ability to incorporate feedback. All the forthcoming challenges should be mitigated by working through resistance by communicating and providing change management workshops, thorough training for technological upgrades, and working through contingent measures on integration issues. Incremental rollout enables management to avoid daily operation disruptions, constantly receiving feedback and making corrections. Set performance metrics and follow them with periodic checks on the redesigned process. Reward or appreciate employee activities to elevate their morale and induce a good feeling for changes. Using such strategies and addressing possible challenges in advance will allow organizations to successfully manage the difficulties of organizing the implementation of a redesigned order fulfillment process, making sure the change will happen smoothly and will be oriented to business needs.

Quantitatively and qualitatively substantiate the benefits of the improved order fulfillment process.

The difference is mainly seen in manufacturing, where the fulfillment process is far better regarding quality and output, so it acts as an enabler for operational excellence. Reduction in lead time along with increased production further provides increased efficiency. It saves costs by using resources, less wastage, and lowers operation overheads.

The first is that the quality improvements are quantifiable regarding reduced defects and errors in the final products delivered. It reduces rework and enhances customer satisfaction and loyalty, which turns into gainful upsell opportunities. This qualitatively adds to applications of advanced technologies and real-time tracking systems that benefit quicker and better order processing, improving both the speed and reliability metrics. Employee satisfaction will increase with more workflows, fewer manual interventions, and appreciation of individual contributions. On the other hand, transparency and improved communication channels will leverage trust in internal and external stakeholder relationships. The increased flexibility of an organization will help respond to the changing demands of the market quickly and use up new opportunities in such a way that it projects itself as agile and customer-focused. In broad lines, the qualitative improvements aim to strengthen both resilience and responsiveness in the order fulfillment process that would validate better the brand image this venture intends to keep up for renewed market strength.

Compare your observations of the organization selected with the academic operations management literature.

Several theories in the academic operations management literature relate to the observable phenomena occurring within shoe manufacturing but in a manner reflecting issues peculiar to this Industry. Efficiency, improvement in quality, and flexibility all reflect three critical criteria for operations management. The tools used in this regard, ranging from Six Sigma to Lean, resonate with this movement of academia toward emphasizing continual improvement and waste reduction.

But the very dynamism of the fashion industry, in general, and in shoe manufacturing, in particular, generates several unique challenges. What is required in point of flexibility and responsiveness – and this in a fast-changing context of people’s taste orientations – becomes all the higher. Such a pressing need for adaptation regarding varying product specifications and market demands is mainly inherent in the very nature of this Industry. Hence, it comes closer to what the literature demands regarding operations: agility.

The application of technology, such as the use of RFID as an inventory management system and AI in quality control, only expresses through them that operational improvement is possible when technological integration sees accomplishment. Other trends in real-time data analytics and automation all reflect similar trends described in the academic discourse on how technology can and should be used to derive efficiency improvements.

Examples can be found in eco-friendly packaging and ethical sourcing efforts. The same approaches are characteristic of new operations in their unique sense—focused on sustainability.

Industry specificity adaptability reveals an overlap in certain key elements of this prominent Industry that adds nuance to better approaches toward requirements for operational strategy adaptation while resonating with the core principles of efficiency, quality, and flexibility. It is often said that academic theory never meets practical life in a dynamic, trend-sensitive manufacturing industry.

References

Abid, M., Mei, S., Nazir, H.Z., Riaz, M. and Hussain, S., 2021. A mixed HWMA‐CUSUM mean chart with an application to the manufacturing process. Quality and Reliability Engineering International, 37(2), pp.618-631.

García-Dominguez, A., Claver, J. and Sebastián, M.A., 2020. Optimization methodology for additive manufacturing of customized parts by fused deposition modeling (FDM). Application to a shoe heel. Polymers, 12(9), p.2119.

Ghahramani, M., Qiao, Y., Zhou, M.C., O’Hagan, A. and Sweeney, J., 2020. AI-based modeling and data-driven evaluation for intelligent manufacturing processes. IEEE/CAA Journal of Automatica Sinica, 7(4), pp.1026-1037.

Gómez-Hernández, J.F., Davia-Aracil, M., Sanchez-Romero, J.L. and Jimeno-Morenilla, A., 2021. An approach to implement STEP-NC in the footwear industry. Computers in Industry, 125, p.103384.

Harrington Jr, J., 2020. Understanding the manufacturing process: critical to successful CAD/CAM implementation. CRC Press.

Hassen, A.A., Noakes, M., Nandwana, P., Kim, S., Kunc, V., Vaidya, U., Love, L. and Nycz, A., 2020. Scaling Up metal additive manufacturing process to fabricate molds for composite manufacturing. Additive Manufacturing, 32, p.101093.

Hojjatzadeh, S.M.H., Parab, N.D., Guo, Q., Qu, M., Xiong, L., Zhao, C., Escano, L.I., Fezzaa, K., Everhart, W., Sun, T. and Chen, L., 2020. Direct observation of pore formation mechanisms during LPBF additive manufacturing process and high energy density laser welding. International Journal of Machine Tools and Manufacture, 153, p.103555.

Intalar, N., Chumnumporn, K., Jeenanunta, C. and Tunpan, A., 2021. Towards Industry 4.0: digital transformation of traditional safety shoe manufacturers in Thailand with developing a production tracking system. Engineering Management in Production and Services, 13(4), pp.79-94.

Kohli, A., Annika, H., Karthik, B., Pavan, P.K., Lohit, P.A., Sarwad, P.B., Patil, A.Y. and Kotturshettar, B.B., 2020, December. Design and Simulation study of fire-resistant biodegradable shoe. In Journal of Physics: Conference Series (Vol. 1706, No. 1, p. 012185). IOP Publishing.

Landers, R.G., Barton, K., Devasia, S., Kurfess, T., Pagilla, P. and Tomizuka, M., 2020. A review of manufacturing process control. Journal of Manufacturing Science and Engineering, 142(11), p.110814.

Liu, C., Huang, Y., Dong, L., Duan, L., Xu, L. and Wang, Y., 2020. Combustion characteristics and pollutants in the flue gas during shoe manufacturing waste combustion in a 2.5 MWth pilot-scale circulating fluidized bed. Waste and Biomass Valorization, 11, pp.1603-1614.

Patel, S.N. and Mukherjee, S., 2022. Manufacturing, characterization, and experimental investigation of the IPMC shoe energy harvester. Journal of the Brazilian Society of Mechanical Sciences and Engineering, 44(1), p.42.

Silvestre, S.E.M., Chaicha, V.D.P., Merino, J.C.A. and Nallusamy, S., 2022. Implementation of a Lean Manufacturing and SLP-based system for a footwear company. Production, 32, p.e20210072.

Spahiu, T., Piperi, E., Ehrmann, A., Almeida, H.A., Ascenso, R.M. and Vitorino, L.C., 2020. 3D printing: an innovative technology for customized shoe manufacturing. In Progress in Digital and Physical Manufacturing: Proceedings of ProDPM’19 (pp. 171-180). Springer International Publishing.

Vieira, M.V., Ferreira, F., Duque, J.C. and Almeida, R.M., 2021. On the packing process in a shoe manufacturer. Journal of the Operational Research Society, 72(4), pp.853-864.

Zolfagharian, A., Lakhi, M., Ranjbar, S. and Bodaghi, M., 2021. Custom shoe sole design and modeling toward 3D printing. International Journal of Bioprinting, 7(4).

write

write