Executive Summary

JAMS Manufacturing is making a giant leap into technology, wherein all computers in all three manufacturing plants and corporate office units are networked in one system. This strategic project aims to concentrate operations, improve communication, and use the best available resources. This project will include the purchase and placement of the necessary systems and facilities, the creation of a connection of local networks, and knowledge courses that will be held for staff. There are a whole lot of advantages to this networking integration as well. This will be a single platform for managing data, making it easier to collaborate in real-time and, of course, simplify the process of accessibility to ICT resources. Another positive impact experienced through the shift was real-time tracking and managing of the production processes, thus increasing production and quality. To guarantee a smooth transition, the project will be presented with a detailed work breakdown structure covering the buying process actions and the designating resources for the training. A cost summary explains the cost facility in detail for a better understanding of budgets and timelines that will guide the implementation process. This paper provides a complete scenario case of JAMS Manufacturing migrating to the networked system that needs to catch up to the chance of gaining the system’s strengths, which include efficiency, employee capabilities, and the ability to compete. To keep the transition to a minimum, the company should make the change as smooth as possible to get the network fully running in no time.

Project Advantages and Changes

The shift of JAMS Manufacturing from the system mode to the network mode is a strategic decision that heralds the beginning of the end of the company’s old way of doing things and ushers in revolutionary thinking. The organized perfection that a network infrastructure brings through makes it the transactional booster. This technology injection will substantially transform the organization and benefit the manufacturing plant and its employees.

Centralization of Operations: This transformation process, driven primarily by the clustering of resources, is at the core of the change. The total system will then be made up of all computers. In the process, JAMS Manufacturing will effectively bring to the forefront a cohesive system that helps to eliminate some repetitive tasks such as data management. Such streamlining of the data will considerably lower the possibilities of wrong data discrepancies in this case, as all departments will work with identical, accurate information (Deflorin et al., 2021). It will also improve the material control with live data from the production floor, which can be accessed immediately by the purchasing and selling departments, resulting in a better resource management context.

Enhanced Communication and Collaboration: This network will be a diverse path for good communication and functions well in multitasking. With interlinking systems, a cross-function of employees will be possible; as a result, they will effectively share the data, avoiding the information barriers between departments. This interconnectedness means processes will be carried out more quickly internally as a result and will have a consequence in setting up a collaborative culture within the organization, allowing workers to work on documents and projects in parallel, regardless of where the workspace is configured.

Resource Optimization: In a networked environment, channeling online tools into investment would optimize the use of resources. Joint availability of shared items like printers, scanners, and servers will remove unnecessary duplication of these units, reducing maintenance and power wastage.

Visible Changes and Employee Experience: The seam will become noticeable to employees as they observe gradual modifications in their physical environment. New devices and software that will be introduced will be the nearest change. Workstations will be reinvented by featuring powerful computers with better processing speeds and additional features. The aesthetic symbol of the network will be its infrastructure, which will be established by installing network cables, routers, and Wi-Fi access points.

Change Management: To manage the impacts of these changes, JAMS Manufacturing will utilize the change management policy comprehensively. Therefore, a wide range of education and training programs will be implemented so employees can operate the system effectively without fear or anxiety. Second-level support will be delivered by its support team to ensure quick response to any technical troubles, thus mitigating the hindrance. Moreover, employee experiences and feedback will be communicated through various channels, making it possible to modify the system in real-time.

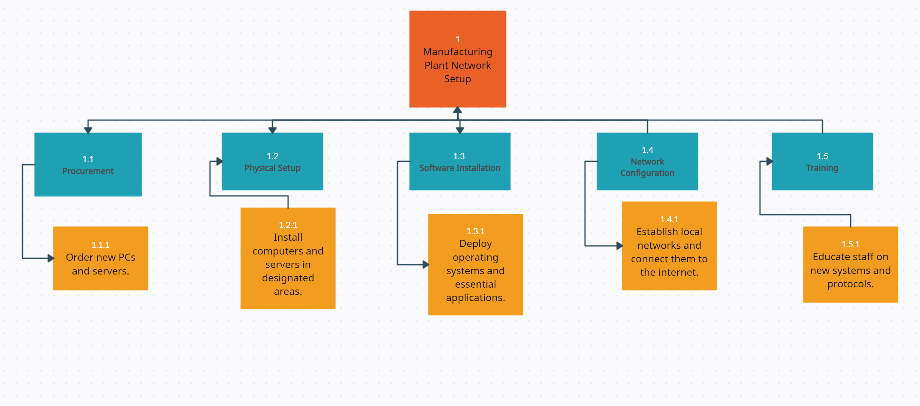

Work Breakdown Structure

Cost Summary

The estimated expenses cover software licensing, hardware expenditures, and labor. The budget will cover the cost of at least four servers, about thirty-five new PCs, networking equipment, and project managers’ and IT specialists’ labor.

Project Timeline

| Weeks 1-2 | Finalize procurement of hardware and software. |

| Weeks 3-4 | Complete physical setup of computers and servers. |

| Weeks 5-6 | Execute software installation and network configuration. |

| Weeks 7-8 | Conduct comprehensive staff training |

| Week 9 | Review and address any post-implementation issues. |

Conclusion

Such a network upgrade at JAMS Manufacturing acts as a landmark event for the firm on the way to its advancement in the technological sector. The strategy of implementing cutting-edge IT infrastructure aims to boost the productivity level and gain an advantage in industry-related competition. Toward this end, a multi-level approach is to be developed to accomplish the following tasks: make the organization leaner and more competitive, promote innovation, and ensure ease of communication at all levels. Incorporating a modern internetwork system will help JAMS Manufacturing company to be more responsive and agile to the market’s demands and meet the customers’ needs; from a consequential viewpoint, it will lead to business growth and success. Next, the upgrading reveals the company’s willingness to spend money on new technologies to ensure employees’ capability of handling innovative skills, improve production levels, and ultimately increase stakeholder value. As JAMS Manufacturing looks to the future, this network upgrade indicates its dedication to continuous improvement and excellence in an ever-evolving global market.

References

Deflorin, P., Scherrer, M., & Schillo, K. (2021). The influence of IIoT on manufacturing network coordination. Journal of Manufacturing Technology Management, 32(6), 1144-1166.

write

write