EHS and Manufacturing Facility

Numerous manufacturing facilities are spread across the country with different employees. Manufacturing facilities are often associated with hazards that can harm employees’ health and well-being (Lee Harrison, 2018). Moreover, employees are exposed to different working conditions and environments that pose risks when working in these facilities. Therefore, manufacturing facilities often have to ensure the safety of their employees by ensuring that the environment in which they are working is protected from hazardous aspects (Lee Harrison, 2018). The EHS initially stands for Environment, Health, and Safety. Therefore, this is an association that fosters environmental health and safety. The body also deals with the health and safety of the employees. These reports show how EHS can benefit a manufacturing facility.

Importance of EHS in a manufacturer facility

The EHS is essential because its primary aim is to seek the employees’ best interests within any given working facility by protecting their health and safety within their working environment. Therefore, the body is essential because it strives to protect employees from hazardous working conditions at their site of work (Leyesa et al., 2020). This is often in working environments that require intensive physical demands and those where toxic substances infiltrate the environment. Imperatively, employee safety should be the responsibility of the employer. However, there are unavoidable situations in which employees find themselves in harm’s way, which often could have been avoided with the help of the EHS.

The EHS aids with developing safety health protocols that organizations can implement to ensure effective preventive measures within the working environment. Moreover, the employee’s health and safety are the foundation of the EHS (Li & Guldenmund, 2018). Any given EHS department will often have an EHS policy and directive that oversees its approach to EHS sustainability. The policy is often similar to the established human resource policies for companies. Consequently, the EHS is vital because it is often used as the background and building block for sustainability and corporate responsibility.

The EHS is also important because it helps protect the environment. It is responsible for establishing regulations guiding organizations to operate environmentally friendly and responsibly (Li & Guldenmund, 2018). It is vital to note that a majority of the manufacturing facilities or heavy manufacturing industries often provide the necessary products for human use but also, in the process, adversely impact the environment through air, water, and land pollution that is often within the surroundings of the industries. The EHS often plays a pivotal role in implementing environmental and resource protection laws for all the people in the country.

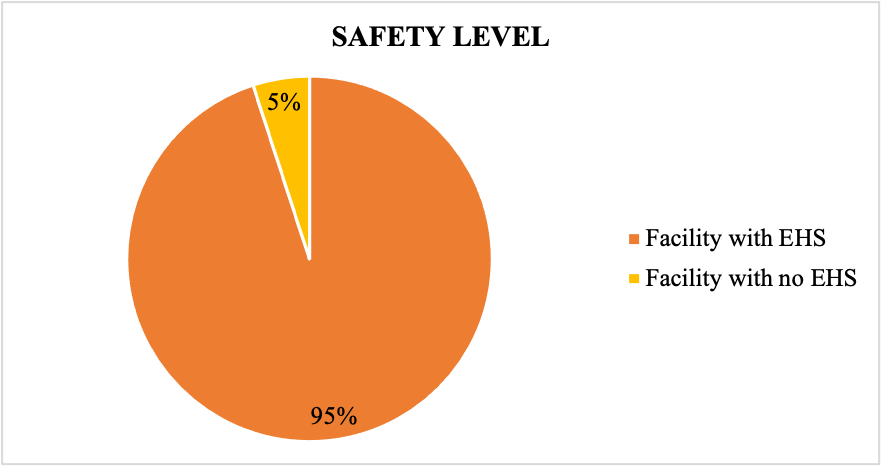

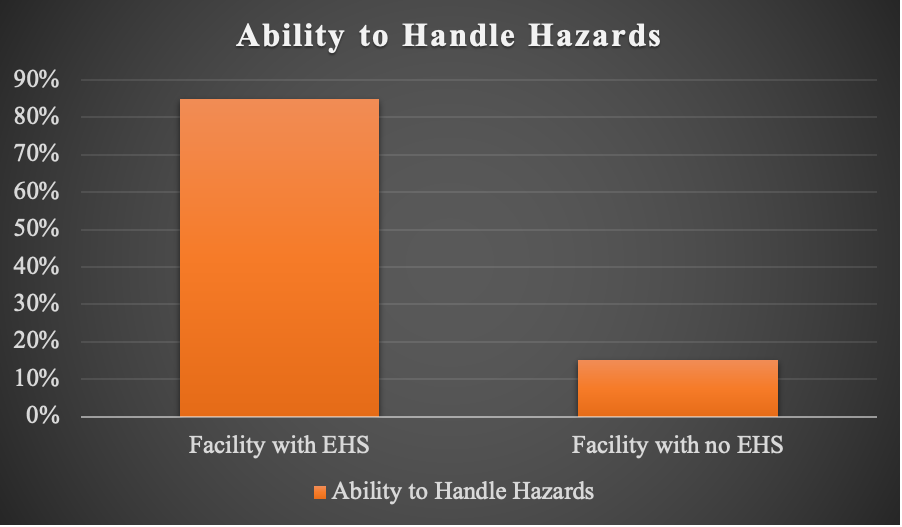

Facilities with an effective EHS program will often have a higher safety level regarding the environment and employees than those without an EHS program.

EHS and a Solar Manufacturer Facility

Recycling

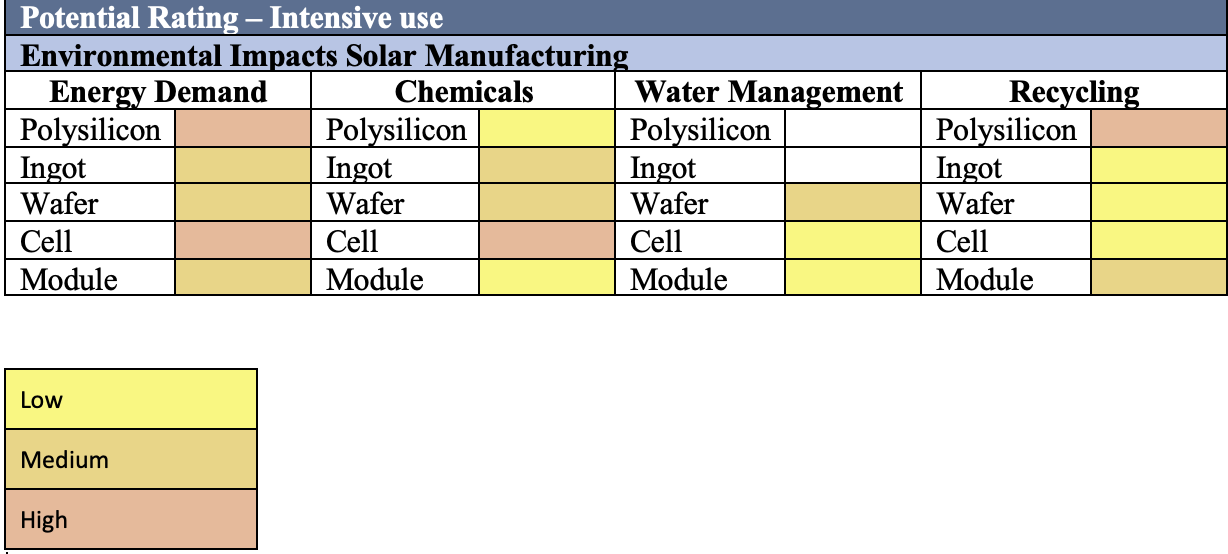

Considering a solar manufacturing facility as a representative of a manufacturing facility, the EHS can be beneficial in waste minimization through recycling. The EHS can provide an effective environmental conservation protocol for establishing sustainability through recycling (Li & Guldenmund, 2018). Therefore, the recycling policy established by a manufacturing facility will be vital in waste minimization through recycling in the given facility. The facility can communicate the recycling information to the workers and the community towards participating in the activity to ensure a safe environment. For instance, the risk for polysilicon recycling in a solar manufacturing facility is high, whereas the risk for recycling wafers, Cells, and ingots is negligible. Further, the risks for the recycling module are minor.

Energy

The EHS can benefit a manufacturing facility by establishing energy conservation guidelines by developing energy management programs. Therefore, it can help a manufacturing facility identify and regularly measure energy aspects within the facility with periodic reporting (Lee Harrison, 2018). This will ensure that the facility upholds energy efficiency in its operation. For instance, in the energy demand of a solar manufacturing facility, the energy demand of polysilicon and Cell have a major risk potential to the environment, and the energy demands for ingot wafers and modules have a minor risk potential to the environment.

Water Management

The EHS can aid a manufacturer in effectively putting measures for effective water management in place by implementing the EHS policy and guidelines on water monitoring and management (Lee Harrison, 2018). These directives include identifying, measuring, and recording the principal water flow within the facility. Further, the guidelines can provide effective water monitoring and management performance to ensure no water waste or pollution. For instance, using an EHS protocol with a solar manufacturing facility, the potential risk for polysilicon and ingot in relation to water management is none-existence, whereas the potential risk of Cell and module in water management is negligible, whereas that for the wafer is minor.

Chemicals

Chemicals are a significant part of environmental hazards that can result from a manufacturing facility. The EHS is vital in ensuring chemical safety in any given facility setting. Moreover, it provides relevant guidance and information on safe practices for handling, disposing, and transporting dangerous chemicals (Lee Harrison, 2018). An example of chemical risk evaluation from a sola manufacturing facility is that polysilicon and module have negligible risk potentials in the environment. Ingot and wafer have a minor risk potential to the environment, whereas Cell has a major risk potential.

Table Shoring Potential Risk Rating

Conclusion

EHS is pivotal for employee and environmental safety establishment. Manufacturing facilities are often associated with hazards that harm employees’ health and well-being. Therefore, manufacturing facilities often have to ensure the safety of their employees by ensuring that the environment in which they work is protected from hazardous aspects. With this duty, the EHS can be very beneficial for manufacturer facilities in ensuring the safety of the employees and the environment surrounding them by establishing effective policies and guidelines that outline the safety protocols to be followed to ensure safety. Those manufacturer facilities with an EHS plan have higher safety levels and an effective ability to handle hazards.

References

Lee Harrison, E. (2018). Environmental, Health, and Safety Auditing Handbook. In modps71.lib. Mutt.ac.th. McGraw-Hill. http://modps71.lib.kmutt.ac.th/handle/123456789/122

Leyesa, M. C., Florencondia, N. T., Villar, M. J. M., & Galman, S. M. A. (2020, December 1). Decision Support System in Environmental, Health, and Safety (DSS-EHS) Management Systems. IEEE Xplore. https://doi.org/10.1109/HNICEM51456.2020.9400126

Li, Y., & Guldenmund, F. W. (2018). Safety management systems: A broad overview of the literature. Safety Science, 103, 94–123. https://doi.org/10.1016/j.ssci.2017.11.016

write

write