Executive Summary

This in-depth report comprehensively analyses operations and quality management at Tesla, Inc., the leading electric vehicle manufacturer. It highlights structural constraints around production efficiency and scalability inhibiting Tesla’s growth and competitiveness. To sustain its pole position, Tesla must invest further in innovation pipelines, supply chain resilience, and scalable quality control frameworks. These are all unique pillars of Tesla’s differentiated operations strategy. While Tesla’s vertically integrated model and extensive automation provide advantages, bottlenecks persist. Enhanced productivity and optimised workflow are essential to boosting output and responsiveness. Strategic alignment between lean operations and bold business goals is analysed, underscoring the need for a greater balance between agility and stability. Supply chain network enhancements and comprehensive performance indicator monitoring will increase end-to-end visibility.

Sophisticated information systems and the latest ICT applications are instrumental to Tesla realising its strategic vision. This project-oriented review spotlights the power of robust methodologies and transformational yet pragmatic leadership. Tesla must continue pursuing advanced innovation while shoring up operational foundations. Increased supply chain transparency, diverse quality assurance mechanisms, cybersecurity investments and formal project portfolios will enable Tesla’s leaders to sustain a competitive advantage. Tesla can resolve critical operational capacity and resilience gaps by implementing these recommendations. Mastering quality and production at scale while retaining flexibility and technological edge will cement Tesla’s pole position in the fast-evolving automotive landscape. This report provides actionable insights into transforming Tesla’s operations and management for the future.

1.0 Operations Principles and Quality Management

Tesla has pioneered electric vehicles but faces operations challenges as it scales. This paper analyses Tesla’s productivity, workflow, supply chain, quality control, information systems, and project management. Core issues include manufacturing bottlenecks, supply chain risks, and product quality oversight. Tesla must improve operational efficiency, supply chain resilience, innovation pipelines, and quality frameworks through advanced capabilities. The paper applies operations concepts like workflow optimisation and vertical integration to evaluate how Tesla’s operations and business strategies align. It examines supply chain design, performance indicators, information systems, and project methodology. Recommendations are provided to bolster Tesla’s production capacity, supply chain agility, and quality control, emphasising data analytics, digitisation, automation, and formal project management. By enhancing operational excellence, management principles, and targeted improvements, Tesla can sustain its pioneering position in electric, autonomous and sustainable mobility amid increasing competition. This paper provides an insightful analysis of Tesla’s operations and practical recommendations.

1.1 Introduction to Tesla

Tesla is at the leading edge of electric vehicles (EVs) and, more broadly, sustainable energy technologies (Cabigiosu, 2022, p.19). Founded by Elon Musk and others in 2003, Tesla has changed people’s attitudes toward electric vehicles, proving that environmentally friendly transportation can also be high-performing (Tran et al., 2020, p. 223). The company’s influence is not limited to automobiles; it invests in energy storage and solar technology. The company’s dedication to innovation is also reflected in its electric cars, including the Model S, 3, X, and Y, whose world-leading technology has led to new quality benchmarks for automotive manufacturers globally (Bao, 2022, p.40).

Tesla leads in the electric car game, establishing standards for range and acceleration and autonomous driving. This has disrupted traditional dealership models and spotlighted Tesla’s ability to stay ahead of industry trends, focusing as it does on its direct-to-consumer sales model and over-the-air software upgrades (Cabigiosu, 2022, p.25). Despite those impressive accomplishments, however, Tesla continues to be plagued by the inevitable pitfalls of its industry. These challenges include handling supply chain disruptions, increasing production scalability, and adapting to ever-changing regulatory regimes (Rogers, 2023, p.45). In addition, the fact that conventional automakers are moving into this market represents both challenges and opportunities for Tesla’s position. How Tesla overcomes these challenges is central to its success in upholding a pioneering position as the leading force for sustainable transportation.

Fig 1. Tesla leads in electronic vehicles (Cabigiosu, 2022).

1.2 Operations Management Challenges

Tesla faces unique operations management challenges as it works to disrupt the automotive industry with its electric vehicles. One major challenge is Tesla’s complex manufacturing processes (Rogers, 2023, p.45). Electric vehicles require high technology, complex parts, and strict quality control (Lebrouhi et al., 2021, p.44). Being able to strike a balance between these factors and still keep operational efficiency up is an ever-present challenge. Facilitating the smooth coordination between sequential processes is particularly important when seamlessly integrating technologies like electric drive-trains and autonomous driving systems. If any link in the chain is broken, it may affect production efficiency and product quality (Lebrouhi et al., 2021, p.33).

Another key challenge for Tesla’s operations is scalability. As electric vehicles are becoming increasingly popular, Tesla must now find the means of increasing production to meet demand (Cooke, 2020, p.20). However, rapid growth puts supply channels, production lines, and workforce management to the test. Scalability issues, such as raw materials for the batteries and hiring suitable personnel to handle them, also require close attention. Preserving this fine balance between the company’s innovative agility and supporting rapid, efficient growth is a complex task that Tesla must continually confront (Cooke, 2020, p.20). Additionally, the global supply chain disruptions witnessed in recent years highlight the importance of Tesla maintaining production despite operational risks. This sets another hurdle for Tesla in achieving a scalable and resilient operation model. However, solving these problems is crucial to maintaining Tesla’s leading role in the electric vehicle market and attaining its long-term operational goals.

1.3 Application of Operations Principles

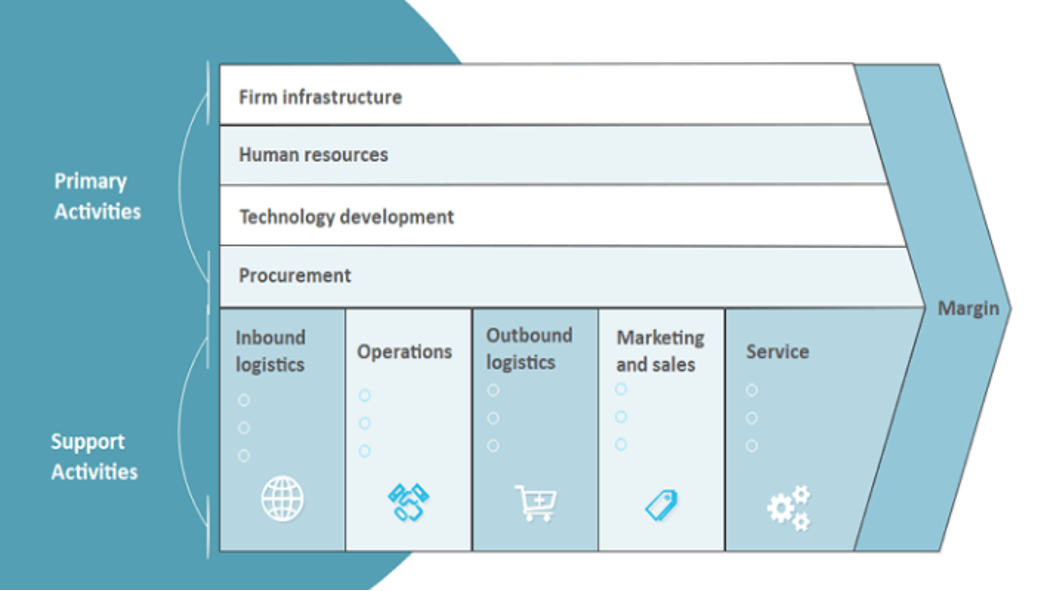

Tesla’s success is largely attributed to its strategic application of operations management principles across its supply chain. Tesla employs core principles, including lean manufacturing, continuous improvement, automation, and vertical integration (Ferreira, 2019, p.20). By adhering to these operational philosophies, Tesla has streamlined production, enhanced quality, and maintained its status as an industry leader.

Integral to Tesla’s operations are lean manufacturing techniques based on the Toyota Production System (Sypko, 2022, p.62). Lean principles aim to maximise value by eliminating waste in processes. Tesla implements lean practices such as efficient material flow, minimised inventories, and enhanced resource utilisation across production. This enables smoother workflow, lower costs, and improved quality control. For example, lean concepts allow Tesla to reduce excess inventory that could lead to storage fees or obsolescence. Lean manufacturing strategies help Tesla extract the utmost value from its production system.

In addition to lean, Tesla is dedicated to continuous improvement or kaizen (Ferreira, 2019, p.20). The company constantly strives to boost productivity by refining processes, updating technology, and innovating systems. Tesla’s automation and advanced robotics exemplify its commitment to kaizen. By integrating cutting-edge tools into manufacturing, Tesla can streamline and enhance workflows. The continuous improvement mindset enables Tesla to sustain efficient output as production scales up. Small ongoing enhancements driven by kaizen accumulate over time into major improvements in productivity and quality. Lean and kaizen provide Tesla with frameworks to eliminate inefficiencies, optimise operations, and maintain excellence.

Furthermore, vertical integration, which refers to a company’s control of multiple or all stages of its supply chain, from raw materials to final products, is a core pillar of Tesla’s operations model. Rather than outsourcing, vertically integrated firms choose to own or internally manage processes from initial production to distribution (Ferreira, 2019, p.24). The concept behind vertical integration is that companies can potentially increase efficiency, reduce costs, and enhance quality or differentiation by directly overseeing successive steps in the value chain. However, the strategy also concentrates risk if any one internal process falters. For Tesla, vertical integration has been a core pillar of its operations model and strategy.

Fig 2. Tesla Value Chain Analysis (Ferreira, 2019, p.24)

While Tesla has seen remarkable success, its ambitious production targets have led to challenges in meeting output levels. Issues like manufacturing bottlenecks have occurred, especially during new product launches (Bhardwaj et al., 2020, p.79). Still, Tesla’s sound application of operations principles positions it well to overcome these hurdles amidst expansion. The company’s lean, continuous improvement, automation and vertical integration strategies should enable efficient, sustainable manufacturing and future innovation.

1.4 Quality Management Framework

Tesla’s quality management system is inseparable from its pursuit of high-performance, reliable electric vehicles. The company emphasises TQM (Total Quality Management) concepts, applying a comprehensive quality philosophy throughout its activities (Taleghani, 2021, p.53). Another focus of Tesla’s quality management is its strict testing and validation procedures for developing vehicles. Materials sourcing, design, manufacture, and testing are all carried out to high standards at Tesla. Maintenance of high quality is important, and the use of advanced technologies like artificial intelligence and machine learning can catch impending quality failures in production very early.

Tesla’s quality management framework extends from the manufacturing floor to customer interactions (Daum, 2022, p.11). The concept of continuous improvement is also evidenced in how manufacturing software updates can be performed over the air to improve products and fix bugs immediately. In addition, it handles any possible pitfalls and establishes a system allowing Tesla vehicles to be continually improved. This aligns with the company’s long-term plans for customer satisfaction and loyalty.

Tesla vehicles consistently meet and surpass industry quality standards, evidenced by high consumer satisfaction ratings that outdo veteran automakers (Saxena and Srinivas 2019, p.394). Tesla’s effective quality control processes, like rigorous testing and data-based improvements, are crucial to this performance. These enable Tesla to produce electric vehicles with advanced features that appeal to consumers. In turn, Tesla is strategically positioned as an innovative, cutting-edge brand. By maintaining rigorous quality management, Tesla can continue delivering products that align with and boost its brand image.

2.0 Impacting Variables, Supply Chain Networks, and Operations Strategies

2.1 Impact of Productivity and Workflow

Productivity and workflow have a tremendous effect on Tesla’s competitiveness, affecting everything from demand to costs and leadership of the industry (Gianolli, 2020, 97). Pursuing efficiency and creativity in production processes is the key to Tesla’s competitiveness. For example, Tesla has been known to use high-tech automation and robotics in its factories. These gigafactories apply the latest technology to improve workflow, reduce production time, and boost productivity for the company (Cooke, 2020, p.30). Besides simplifying the performance of such repetitive work, the application of automation can accurately assemble parts and help ensure that quality control remains high.

At the same time, Tesla’s vertical integration reduces its efficiency and ability to compete (Chen et al., 2019, p. 42). With this strategy, Tesla reduces its dependence on suppliers by manufacturing some of its more important components in-house (including batteries and electric powertrains), streamlining the supply chain, and gaining greater flexibility over the production process. This system increases productivity by cutting down delays in obtaining components and allows Tesla to respond rapidly to market demands. In addition, Tesla runs a just-in-time organisation, with inventories as low as possible. This reduces storage costs and avoids stockpiling inventory, factors all important in a still-growing and changeable electric vehicle market (Chen et al., 2019, p. 47).

Aside from this, the use of Industry 4.0 concepts by Tesla, such as data-driven operation and the Internet of Things (IoT) to increase efficiency further enhances efficiency. (Krishnan et al.,2022, p.789). Real-time big data analysis allows Tesla to track and improve production processes around the clock. For example, the firm utilises information generated by sensors on its production line to detect inefficiencies and impending equipment breakdowns, thereby enabling more active adjustments of its overall workflow (Krishnan et al.,2022, p.792). In addition to efficiency, this data-driven approach is perfectly suited for cultivating a culture of continuous improvement that puts Tesla at the forefront of the electric vehicle market.

2.2 Operations Strategies’ Alignment with Business Strategies

All of Tesla’s operations strategies are closely tied to the company’s business strategy and together make up a mutually supporting cycle that helps clarify its uniqueness within the automotive industry (Sypko, 2022, p.62). A key factor is Tesla’s devotion to innovation in products and production. Producing leading-edge electric vehicles (EVs) is an operations strategy central to the company’s business model (Schadlow et al., 2021, p.89). Through its technical innovations in batteries, electric drive systems, and autonomous driving platforms, Tesla has become a focal point of the automobile market. This is made possible through its strategy of producing differentiated, high-quality EVs that appeal to environmentalists who also demand the latest stability and safety features in a vehicle. By aligning its operations and business strategies around innovation, Tesla has been able to disrupt the automotive space with its cutting-edge electric vehicle technology and performance.

However, incidents of software flaws and technical breakdowns involving such systems have led to questions about their safety among consumers and industry specialists alike. This indicates that Tesla should better innovate by balancing further technological advances and the stability of its products, thereby successfully responding to such potential threats as safety guarantees or quality controls.

Another major operations strategy consistent with Tesla’s business objectives is its focus on sustainability and environmental responsibility. Tesla’s sustainability efforts include incorporating sustainable practices in its supply chain, manufacturing processes, and vehicle materials (Yang et al., 2022, p.26). Such environmental consciousness is a self-contained campaign and a part of Tesla’s branding and market strategy. This explains how sustainability united operations and business strategy and became the key to cultivating an environmental brand positioning for Tesla.

However, there are some environmental and ethical issues surrounding the various materials required for batteries. The mining and refining tech minerals such as lithium and cobalt have also brought up issues regarding the overall ecological impact or supply chain ethics (Deberdt and Le Billon, 2021, p.102). In addition, Tesla needs to strengthen its attention and consciousness about sustainable resources, whether in terms of environment or ethics. It should strengthen its commitment to sustainability and provide a more comprehensive environmental focus.

In addition, Tesla’s direct sales channel and unusual marketing strategy strengthen the company’s operations and business goals (Du et al., 2021, p.79). Tesla cut out traditional dealership networks, and dealing directly with consumers can have more control over its sales channels and better understand consumer demand. This ties into Tesla’s thinking: establishing a brand that breaks traditional automotive expectations. However, counter-cultural Tesla’s direct-to-consumer sales approach may also appear to have run afoul of legal and regulatory structures in many places. However, they overlook that traditional dealership networks and industry rules protecting consumers ‘interests take away market access choices. To better integrate its sales strategy with overall business objectives, Tesla must overcome these regulatory difficulties (Du et al., 2021, p.81). Market competitiveness, a wide choice of vehicles for consumers to choose from, and meeting the requirements stipulated in its regulations without departing from or weakening this unique direct-sales strategy.

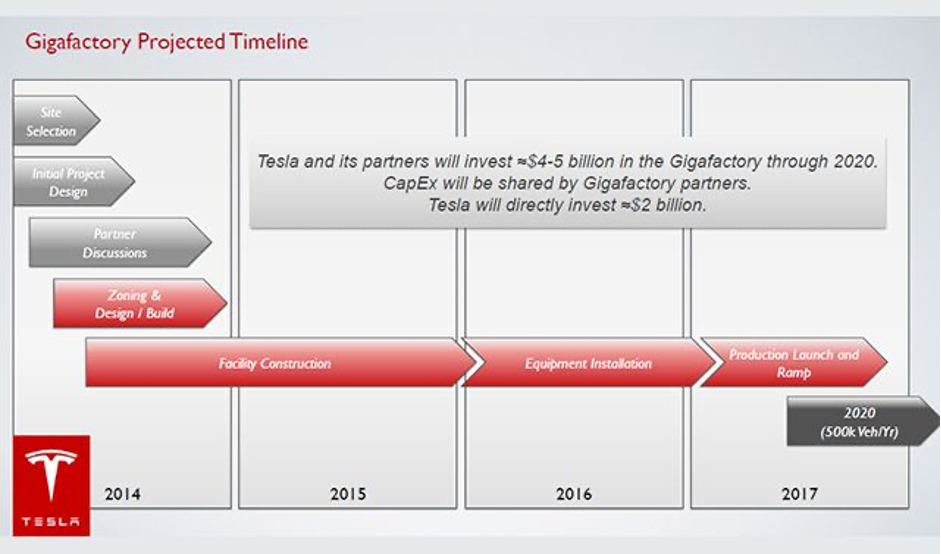

2.3 Supply Chain Network Design

Tesla’s vertically integrated supply chain stands apart from most automakers and is a source of competitive advantage. Unlike rivals, Tesla owns its battery and drive-train factories rather than outsourcing. This grants unparalleled oversight and control versus automakers relying on hundreds of third-party suppliers (Cooke, 2020, p.38). For example, Toyota relies on suppliers for most components and only handles final vehicle assembly in-house. In contrast, Tesla’s gigafactories enable complete control over battery and drive-train production, which are the most technology-intensive and proprietary aspects of its electric vehicles. By minimising outsourcing these core components, Tesla reduces the risks of shortages or quality issues from external vendors. This insulates Tesla from supply uncertainties and facilitates rapid design improvements to batteries and powertrains.

Other electric vehicle makers are also heavily dependent on outside suppliers. Nissan sources batteries from LG and modules from Bosch among over 500 suppliers while only producing motors and assembling final vehicles (Bao, 2022, p. 43). Similarly, Volkswagen relies extensively on component purchases from vendors, including Samsung SDI, for batteries. Rivian, another newer electric vehicle startup, also depends on suppliers like LG and Samsung SDI for batteries and Bosch for electronics (Bratianu et al., 2023, p.76). This demonstrates that even rivals pursuing electrification remain anchored to traditional high-outsourcing models.

In contrast, vertical integration has allowed Tesla to scale and innovate faster than its peers. Direct control over its Gigafactories enabled rapid production ramp-up for the Model 3, and Y. Competitors lacking such internal capacity have struggled to increase electric vehicle volumes quickly (Bridge and Faigen, 2022, p.89). Additionally, in-house component manufacturing facilitates the co-design of batteries, motors and overall vehicle architecture – enabling tight technical integration.

Fig 3. Tesla’s Gigafactory Supply Chain Vertical Integration (Vikram, 2023)

Tesla’s vertically integrated supply chain provides the company with a competitive advantage. By minimising outsourcing and directly managing the production of proprietary components, Tesla exerts end-to-end control over its supply network. This enables operational continuity and the rapid incorporation of innovations into new vehicle designs. Tesla’s supply chain architecture directly reinforces its strategy as a nimble, tech-driven automotive leader.

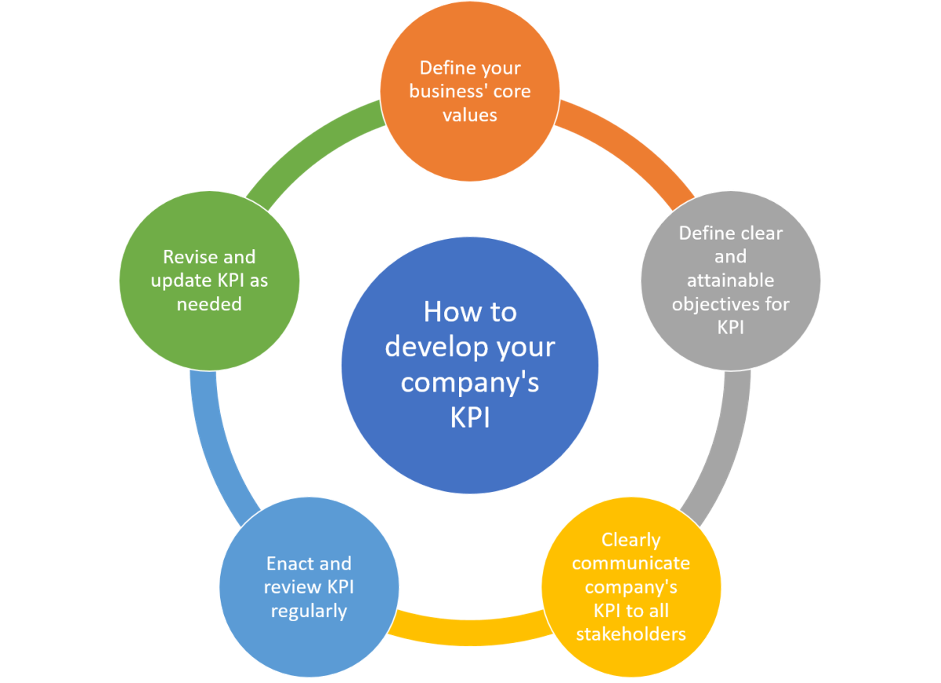

2.4 Performance Indicators Implementation

Monitoring key performance indicators (KPIs) is critical for Tesla to control and continuously improve its manufacturing and supply chain operations as the company scales up production (Sharma et al., 2023, 38). Core manufacturing KPIs that Tesla tracks include production cycle time, yield, defect rates, and scrap. These metrics identify production inefficiencies and bottlenecks so issues can be addressed. Tesla measures supplier reliability, inventory turnover rates, and order lead times for supply chain management. This promotes cost-efficiency and responsiveness in procurement.

Fig 4. Tesla, Inc: An Organisational Performance Analysis (Sharma et al., 2023, pp.38)

Additional KPIs Tesla could implement to optimise operations further are quality rates like percentage of rework, maintenance metrics like mean time between equipment failures, safety incident rates, and sustainability factors such as energy use per vehicle produced. Ongoing monitoring of a wide-ranging set of KPIs across the value chain gives Tesla the necessary visibility to pinpoint problems rapidly (Taschner and Charifzadeh, 2023, p.215). This enables targeted continuous improvement initiatives. For example, high scrap rates could trigger redesigning faulty manufacturing stages, while slow inventory turnover could incentivise supplier negotiations to improve order flexibility. Tesla’s extensive use of key performance indicators is integral for maintaining operational excellence and advantage as market complexity increases.

3.0 Role of Management Information Systems (MIS) and Information and Communications Technology(ICT)

3.1 MIS in Achieving Strategic Goals

Tesla strategically employs management information systems (MIS) across functions to enable data-driven decision-making and efficient, agile operations in line with its mission as an innovative automotive company (Koskinen et al., 2019, p.19). MIS, comprising integrated people, processes, data, hardware and software, is critical for Tesla in areas ranging from manufacturing to inventory control.

Engineers and designers using computer-aided design (CAD) software and simulations exemplify how the people interacting with MIS bolster Tesla’s research and new product development. By digitally designing and testing prototypes, Tesla can accelerate design with fewer physical prototypes (Kumari and Bhat, 2021, p.206). With CAD and simulation applications as its new engines, this rapid iteration makes it possible for Tesla to introduce new vehicle models and new features more quickly, which is an important part of their strategy. Similarly, executives use data from Tesla’s MIS, including data analytics and dashboards, to control high-level strategic planning based on market trends.

As for business processes, MIS helps improve automated assembly because networked sensors monitor the status and performance of the production line, defects, and bottlenecks, all in real-time (Kumari and Bhat, 2021, p.206). MIS presents live operational data, allowing rapid issue identification and correction to improve the manufacturing process. This fits Tesla’s strategy of improving product quality and timeliness of delivery. In the same way, combining sales, inventory and logistics data supports predictive inventory management to match supply with demand. An optimised inventory saves costs and prevents shortages affecting customer service.

The data provided by MIS systems across divisions gives Tesla unparalleled visibility into core operations, helping identify areas for improvement. Analysing MIS data on customer lead times, quality rates, maintenance metrics, and even sustainability factors facilitates data-driven decision-making for continuous enhancement (Kumari and Bhat, 2021, p.206). Data-enabled performance management and forecasting ultimately translate into strategic advantages for Tesla.

Moreover, the physical IT infrastructure, including networks, servers, and data centres that support Tesla’s vast MIS capabilities, is equally critical (Koskinen et al., 2019, p.19). Smooth, uninterrupted MIS functionality relies on robust infrastructure with ample capacity, redundancy, and security. Outages could cripple production or supply chain coordination. By keeping infrastructure reliable and secure, Tesla ensures its MIS sustains operations.

Additionally, the custom software suite powering everything from Tesla’s automated assembly lines to its integrated inventory and logistics analytics provides comprehensive monitoring and control (Koskinen et al., 2019, p.19). Advanced algorithms optimise processes, while dashboards present key performance indicators. This software is the lever that realises the strategic potential of Tesla’s data, infrastructure, and capabilities.

However, Tesla can improve its MIS strategy. Enhanced cybersecurity is needed to protect operational data and consumer privacy (Koskinen et al., 2019, p.19). Backup infrastructure should also be expanded to minimise disruption risks. Furthermore, demand forecasting algorithms require continual refinement to account for economic shifts and new data sources, supporting nimble inventory management.

Overall, Tesla reaps immense strategic benefits from its coordinated implementation of capable people, efficient processes, actionable data, robust IT infrastructure, and tailored software applications in its management information systems. However, sustained vigilance and improvement of MIS remain vital for Tesla to execute its long-term vision. MIS both enables and requires an agile, innovative mindset.

3.2 ICT Applications in Operations Management

Tesla relies heavily on information and communications technology (ICT) to enable its manufacturing and design processes. Like other major automakers, Tesla extensively uses automation and robotics in vehicle manufacturing. However, Tesla’s approach stands out in its more streamlined production system with fewer model variations, allowing greater integration of proprietary automation technology (Kumari and Bhat, 2021, p.206). By manufacturing its motors and batteries, Tesla also has tighter control over these critical components than most automakers that outsource them. ICT enables rapid iteration in Tesla’s manufacturing, including over-the-air software updates that frequently upgrade vehicle systems and manufacturing processes. Simulation and virtual modelling are used extensively in designing and validating manufacturing lines before implementation.

While Tesla’s spending on ICT is not transparent, estimates indicate it may invest around $1 billion annually on research and development, including ICT – high for its size but lower than larger automakers (Bhardwaj et al., 2020, p.84). Advanced ICT provides operational advantages for Tesla but risks complacency as traditional automakers ramp up technology investments to compete. On the design side, Tesla leverages ICT tools like virtual and augmented reality to enable interactive 3D modelling and collaboration (Kumari and Bhat, 2021, p.210). This immersive approach can accelerate design cycles, spur creativity, and support geographically distributed teams. However, constant upgrading of design ICT tools poses challenges for training and adjustment as employees must stay adept with the latest tech. Cybersecurity and privacy risks also rise with the increased use of interconnected ICT systems, requiring mitigation measures to secure proprietary designs and customer data.

Furthermore, greater transparency on Tesla’s ICT investments could highlight its technology focus while reassuring that it balances cutting-edge innovation with operational stability. For any automaker, succeeding in the 21st century will increasingly depend on strategically leveraging ICT to maximise productivity while minimising disruption (Kumari and Bhat, 2021, p.117). As a leader in bringing Silicon Valley software expertise to the automotive sector, Tesla’s ability to harness the power of ICT while navigating its risks will be an important competitive factor going forward.

3.3 Requirements, Methods, and Technologies

Tesla uses a variety of demands, standards, and advanced technology (such as large-scale AI) to reduce operational inefficiency with excellence. The use of data-oriented decision processes is one important prerequisite (Cooke, 2021, p.33). Tesla applies big data from vehicle sensors, production processes, and consumer interactions. Using cutting-edge analysis and machine learning, Tesla can draw actionable insights from this information to inform its decision-making process and facilitate operational improvements.

Tesla’s autonomous driving is a good example of how the company uses AI. The company uses machine learning to improve the Autopilot system’s capabilities. They help Tesla vehicles learn from real-world experiences, enhancing their capability to adapt to different environments and uncertain road conditions (Centobelli et al., 2022, p.59). Continuous improvement of Tesla’s autonomous driving capabilities is due to this accumulation and fits in with the company strategy of breaking new ground.

In addition, new technologies like the Internet of Things (IoT) and edge computing are essential to making Tesla more efficient (Zhang and Letaief, 2019, p.246). Tesla’s vehicle and manufacturing system are linked together, enabling real-time monitoring of each device. For example, sensors installed in production equipment equipped with the IoT can give quick feedback on performance, allowing for preventive maintenance and reducing downtime. This allows for greater operational efficiency and dovetails with Tesla’s emphasis on using technology to improve continually.

However, it still deserves careful consideration, given that Tesla integrates demands, standards, and even cutting-edge technologies like large-scale AI to realise its operational efficiency. However, it does not explicitly define what demands and standards are required, so there still needs to be more clarity on the core issue (Zhang and Letaief, 2019, p.254). What is more, concrete examples of data-driven decision-making and critical reflection on the ethical and safety dimensions of artificial intelligence are needed to sustain reasoned analysis. Passing reference to integration between the IoT and edge computing calls for further discourse on applications in this area as well as issues that need to be addressed. Recognising the possible dangers and restrictions of these technologies would provide a more fair-minded assessment.

4.0 Project Management Methodology

4.1 Application of Project Methodology

To resolve the problems within these weak links, Tesla uses a systematic project methodology (Breyter, 2022, p.6). Realising the importance of formal methods starts with project objectives and project outlines. The second stage of this process is to fully assess the operational problems mentioned in that report, averting any project from being a one-size-fits-all approach or focusing on non-critical areas. After that, Tesla deployed effective tools for project management scheduling, such as Gantt charts and Work Breakdown Structures (WBS), to plan and carry out the identified programs (Breyter, 2022, p.18). Gantt charts give concrete visions of tasks and timelines, helping to assign resources and monitor progress, while WBS helps subdivide large projects according to convenient reference units.

Developing detailed specifications upfront aligns teams and enables rapid iteration within defined parameters at Tesla. During this stage, the company creates specified project requirements that describe goals, expected deliverables, schedules, and personnel allocation needs (Lehtinen, 2023). This allows all interest groups to be on the same wavelength, eliminating uncertainty and guaranteeing that projects proceed smoothly in the right direction. Tesla brings together project specifications and scheduling functions, providing the blueprint for meeting a company’s goals while facilitating the open exchange of information. These deployments of the project spirit and Tesla’s use of scheduling tools such as spreadsheets or specialised software programs combined with clear specifications for each task show that it is determined to treat operational risks systematically (Cuypers, 2023, p.23).

4.2 Contribution of Project Leadership

Project leadership at Tesla enables change and project achievement by focusing on the human angle. Leadership at Tesla, especially under Elon Musk’s leadership style, stresses transformative and visionary project management (Carr, n. d). Innovation, risk-taking, and pursuing ambitious goals are defining traits in Musk’s leadership style. However, he gives the project teams a sense of mission and haste, encouraging them to innovate and improve. This visionary approach also promotes an outward-looking spirit, which helps Tesla address problems with creativity and extend the bounds of what is possible in automobiles and energy.

Tesla’s project leadership strategies extend beyond traditional hierarchical structures. The company stresses cooperation and cross-functional teamwork, emphasising mutual communication. This participatory leadership culture allows employees at every level to be involved in project innovation and solving problems (Kim, 2023, p.73). Furthermore, Tesla’s leadership uses open channels of communication to manage stakeholders’ expectations. Regularly imparting information, setting clear goals, and emphasising common objectives all help to foster team spirit. Though Tesla has benefited from Musk’s leadership, maintaining its viability in long-term competition will depend on a constant approach to adapting and improving strategy.

4.3 Managing Stakeholder Expectations

Controlling stakeholder expectations is particularly important given the rapidly evolving nature of both the automotive and energy industries. Tesla, headed by Elon Musk, sees stakeholders as a wide range of constituencies, from investors and customers to employees and officials. Tesla recognises the existence of different expectations and interests, so communicating with them to get their enthusiasm on track is critical. Transparent and open communication channels are created to update stakeholders on progress, challenges, and results (Kim, 2023, p.73). With this proactive approach, not only is there mutual trust and a low chance of misunderstandings, but the stakeholders are even better-informed contributors to project success.

To manage stakeholders’ expectations, Tesla uses regular updates and communication meetings (Tsai, 2021, p.308). It also integrates the opinions of concerned parties into its decision-making process. Through actively soliciting stakeholder views, Tesla can look to alleviate concerns and use the insights gained for project improvement. Also, the company considers how its projects affect society at large. This reflects a common sustainability and social responsibility standard all companies hold nowadays. Adopting this whole-body management system has not only protected Tesla’s image from excessive criticism but also provides a good foundation to build relations with all the stakeholders on both sides that will enable them to pass their projects through smoothly and finally open successfully. Now that Tesla is forging an elephant-sized hoofprint to stamp deeper outside America while mastering electric vehicles and renewable energy technologies, smooth handling of existing stakeholders will be key.

Conclusion

In conclusion, a thorough look at Tesla’s operations and quality control reveals some important facts. Production efficiency and scalability Structural limitations both inhibit Tesla’s expansion and reveal the need to invest more in innovation management and improve the performance of its supply chain. Other things about the previous experience: aspects of twentieth-century-era Taiwan that were unique to its operations strategies, such as extensive automation and vertical integration, bring differentiation. However, these also bring a concentration of risk. Quality requires the use of very strict quality frameworks. Without such quality frameworks, Tesla cannot maintain its brand as a technology innovator. Application-related demand for strong data security and workforce skills greatly benefits information systems and ICT.

Besides, Tesla’s project-based method that involves joining formed teams requires robust, detailed specifications and the ability to reconcile the varied needs of various pressures. Proper management and formal project methods enable strategies to be realised. Tesla must consistently pursue advanced innovation while maintaining operation stability, using information communications and technology (ICT), quality control, robust supply chain, and organised project execution to maintain its market supremacy. There must be an answer to these two types of connected problems; otherwise, competition will become increasingly fierce. However, Tesla has shown its ability to adapt and technology focus to turn its competitive advantage into another.

REFERENCES

Bao, C., 2022, July. Inferring the Future of the Electric Vehicle Industry from Tesla’s New Business Model. In 2022 2nd International Conference on Enterprise Management and Economic Development (ICEMED 2022) (pp. 40-45). Atlantis Press.

Bhardwaj, S., Pandey, R., Sharma, S., Sejal, S., Iyer, G., Sharma, S., Ranjith, P.V. and Kulkarni, S., 2020. Problems faced by automobile industries: Case study on Tesla. International journal of Tourism and hospitality in Asia Pasific (IJTHAP), 3(2), pp.78-88.

Bratianu, C., Stănescu, D.F. and Mocanu, R., 2023. The mediating role of customer knowledge management on the innovative work behavior and product innovation relationship. Kybernetes, 52(11), pp.53-84.

Breyter, M., 2022. The Role of Project and Product Management in Software Delivery and IT Services. In Agile Product and Project Management: A Step-by-Step Guide to Building the Right Products Right (pp. 3-22). Berkeley, CA: Apress.

Bridge, G. and Faigen, E., 2022. Towards the lithium-ion battery production network: Thinking beyond mineral supply chains. Energy Research & Social Science, 89, p.102659.

Cabigiosu, A., 2022. Sustainable development and incumbents’ open innovation strategies for a greener competence‐destroying technology: The case of electric vehicles. Business Strategy and the Environment, 31(5), pp. 15-36. https://doi.org/10.1002/bse.3023

Carr, R., Praise for Business Leadership Under Fire.

Centobelli, P., Cerchione, R., Del Vecchio, P., Oropallo, E. and Secundo, G., 2022. Blockchain technology for bridging trust, traceability and transparency in circular supply chain. Information & Management, 59(7), p.103508.

Chen, Y., Chowdhury, S.D. and Donada, C., 2019. Mirroring hypothesis and integrality: Evidence from Tesla Motors. Journal of Engineering and Technology Management, 54, pp.41-55.

Cooke, P., 2020. Gigafactory logistics in space and time: Tesla’s fourth gigafactory and its rivals. Sustainability, 12(5), p.20-44.

Cooke, P., 2021. 2. From the machine learning region to the deep learning region: Tesla, DarkTrace and DeepMind as internationalised local to global cluster firms. The Globalization of Regional Clusters: Between Localisation and Internationalisation, p.33.

Cuypers, P.W., 2023. Mastering Project Uncertainty: A Systems Thinking Approach. Taylor & Francis.

Daum, T., 2022. Agile Methods on the Shop Floor: Towards a” Tesla Production System”?.

Deberdt, R. and Le Billon, P., 2021. Conflict minerals and battery materials supply chains: A mapping review of responsible sourcing initiatives. The Extractive Industries and Society, 8(4), p.100-935.

Du, X. and Li, B., 2021, December. Analysis of Tesla’s Marketing Strategy in China. In 2021 3rd International Conference on Economic Management and Cultural Industry (ICEMCI 2021) (pp. 79-87). Atlantis Press.

Ferreira, M.B.D.C., 2019. Tesla and the electric vehicle market in 2018 (Doctoral dissertation).

Gianolli, F., 2020. The Fourth Industrial Revolution and the future developments in the automotive industry.

Kim, S., 2023. Entrepreneurial CEO’s Intended Public Language Clarity as a Strategic Tool for Corporate Communication: Linguistic Analysis of Automotive Industry Leaders. Global Business Review, p.09721509231178973.

Koskinen, K.M., Lyyra, A., Mallat, N. and Tuunainen, V., 2019. Trust and risky technologies: Aligning and coping with Tesla Autopilot.

Krishnan, T., Khan, A. and Alqurni, J., 2022. Aggregate production planning and scheduling in the Industry 4.0 environment. Procedia Computer Science, 204, pp.784-793.

Kumari, D. and Bhat, S., 2021. Application of artificial intelligence technology in tesla-a case study. International Journal of Applied Engineering and Management Letters (IJAEML), 5(2), pp.205-218.

Lebrouhi, B.E., Khattari, Y., Lamrani, B., Maaroufi, M., Zeraouli, Y. and Kousksou, T., 2021. Key challenges for a large-scale development of battery electric vehicles: A comprehensive review. Journal of Energy Storage, 44, p.103273.

Lehtinen, G., 2023. Real Time Insights for Shared Manufacturing-A Multi-Company Reporting Solution.

Pearlson, K.E., Saunders, C.S. and Galletta, D.F., 2024. Managing and using information systems: A strategic approach. John Wiley & Sons.

Rogers, D., 2023. The Digital Transformation Roadmap: Rebuild Your Organisation for Continuous Change. Columbia University Press.

Saxena, M.M. and Srinivas Rao, K.V.N., 2019. Quality management, total quality management, and six sigma. International Journal of Scientific and Technology Research, 8(12), pp.394-399.

Schadlow, N., Herman, A. and Helwig, B., 2021. Powering Innovations: A Strategic Approach to America’s Advanced Battery Technology. Hudson Institute.

Sharma, A. and Kumar Tiwari, M., 2023. Digital twin design and analytics for scaling up electric vehicle battery production using robots. International Journal of Production Research, 61(24), pp.12-46.

Sypko, D., 2022. Time-Based Competition in Tesla´ s Supply Chain in the Era of Industry 4.0.

Taleghani, A., 2021. Impact of Total Quality Management Practices on Corporate Sustainable Development with Emphasis on Green Innovation in Manufacturing Companies (Case Study: PARS KHAZAR Industrial Company in Iran) (Doctoral dissertation, Politecnico di Torino).

Taschner, A. and Charifzadeh, M., 2023. Performance measurement in supply chains. In Management accounting in supply chains (pp. 209-279). Wiesbaden: Springer Fachmedien Wiesbaden.

Tran, B., Zhang, D., Al Gafly, M., Akhter, T., Lilithcleopatra, J., Daim, T.U. and Meissner, D., 2020. Elon Musk Transportation Projects. Innovation Management in the Intelligent World: Cases and Tools, pp.213-232.

Tsai, H.Y., 2021. The impact of artificial intelligence on sustainable corporate brand: a netnography study of Tesla (Master’s thesis, H.-Y. Tsai).

Yang, Z., Huang, H. and Lin, F., 2022. Sustainable electric vehicle batteries for a sustainable world: Perspectives on battery cathodes, environment, supply chain, manufacturing, life cycle, and policy. Advanced Energy Materials, 12(26), p.2200383.

Zhang, J. and Letaief, K.B., 2019. Mobile edge intelligence and computing for the internet of vehicles. Proceedings of the IEEE, 108(2), pp.246-261.

write

write