Specifically, yield optimization is using data analytics to boost a company’s sales and profitability. People need to be competitive since the corporate world is so fiercely competitive. However, due to intense competition, firms must maximize their efficiency to succeed. Each investor in a company wants to realize the possible profit from their investment (Basar et al. 2021). This continual corporate procedure called yield optimization may be applied even in nonprofit institutions. Therefore, to be able to get information and trends from the data, it is necessary to use effective data-gathering procedures. The optimizing stage involves a few phases.

Stage of Research and Collecting Information

The least essential phase of optimization involves discovery. A thorough grasp of the organizational processes is necessary for the discovery stage. The stage is also where data collecting within the company takes place. A diagnostic of whatever is possibly problematic regarding manufacturing operations might be made using the data gathered. A system for how the process might be improved can be developed with the use of an understanding of the process. The business would need to comprehend why each step functions to enhance that workflow. However, the process of discovering the procedure may also involve phases:

First is to evaluate the project’s contributions: Each manufacturing step requires input. Therefore it is essential to streamline or comprehend the input process to ensure the entire industrial process runs smoothly. There are several things to consider when it comes to input (Han, Shin & Choi 2019). The price of input would be the first. Other workable options should be examined and evaluated to determine whether they are less expensive without sacrificing the superiority of the final product. Typically, the caliber of the input would be the subsequent one. A poor-quality product entering the industrial process may result in less output, more waste, or even inefficiency across the whole procedure.

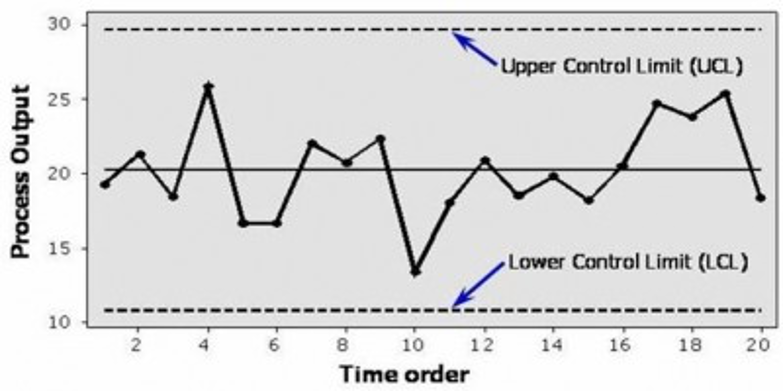

The production stage ought to come next: Numerous procedures are involved in the manufacturing phase, and much data should be collected now. The actions that must be done to achieve the project’s aim should be explained in-depth, along with the critical processes that must be understood. It is essential to gather information that may be utilized to gauge how effective each stage of the production cycle is. Notably, a vital aspect of statistical evaluation and Statistical Process Control is good data collection (refer to Diagram 1)—procedures for identifying when a process has gotten out of hand. The method of gathering data will be essential for aiding in comprehending the organization.

Diagram 1 illustrates statistical process control that shows when processes are inside control boundaries.

Analyzing the materials used in the manufacturing method is crucial in understanding the operation. To make selections more straightforward, being aware of the materials and machinery’s limits is essential. The possibility of replacing the supplies if they are not as effective as those on the market should also be recognized. Additionally, the stage calls for a thorough awareness of the business procedures and upgrades. Research of prior effective strategies and why they were effective or even why they weren’t should be conducted.

Conceptualization

Conversely, the process of thinking and creating ideas is known as the ideation stage. The brainstorming process is intricate and must be available to a select group. The procedure calls for individuals with specialized abilities, and a wide range of problem-solving strategies might be used. However, investigating how various individuals have solved the problem would be the first step (Liu, Bettis & Burke 2020). Several entities could have attempted to approach the issue especially, making them appropriate candidates for investigation on stage. Other individuals may have already had a problem comparable to this one.

Another essential component is the mediation of the problem-solving conversation. Experts in the subject and those who could be familiar with the various procedures in question should thoroughly debate each concept. They should be able to use their particular set of skills to contribute to the development of a solution. Someone with the appropriate abilities could solve the issue that plagues business operations.

Strategic Planning

Idealistically, according to Ahmad and Ahmad (2019), the next critical phase in operational optimization is developing a plan. The formulation of an approach must focus on tackling major and minor issues. A sound plan should be developed while considering the company’s costs. Therefore, a cost-benefit analysis is crucial to ensure the business can withstand the significant shifts. A cost-benefit analysis should determine if the expenses incurred or the concessions made to the strategy are justified in light of the advantages that the firm will get. Consequently, depending on the advantages or disadvantages they present to the company, different tactics may be accepted or rejected.

Furthermore, the next phase in the strategy creation process is ensuring the produced strategies are scalable. Scalability is a significant problem in the changing corporate environment. A plan may only be financially feasible to invest in if it is scalable. A strategy being created should have the ability to adjust. Adapting to an ever-evolving business climate should be a vital component of any plan designed to ensure the company’s long-term success. Accessibility is an excellent technique to ensure a company is practical and high-quality. Consequently, it is crucial to consider whether the tactics created will satisfy future corporate requirements.

Likewise, testing the established strategy is the last phase in the strategy creation process. The testing phase can take many forms depending on the business’s size and goals. Some companies may afford to run the systems or apply the techniques in a smaller business unit as a trial project before implementing them. Other businesses may perform assessment and testing by considering earlier companies and the advantages of comparable techniques they enjoyed.

The implementation

Regarding operational yield optimization, deployment is a crucial step. Putting the developed plan into practice is known as implementation. Nevertheless, a plan of action produced during the strategy formulation phase must be supported by data showing effectiveness. Implementing projects would be essential for developing company ideas and determining the best strategy for making them successful. Thus, the stage is dependent on earlier phases. A solid framework for execution might be achieved with effective strategy creation.

Typically, the implementation step must be carried out in various ways. Multiple firms could use different strategies for implementing strategies. A thorough transition process may be necessary for some businesses or even procedures. Others can adopt a more cautious approach by monitoring the results of the transition process incrementally as it is put into practice. People would have varied preferences depending on their systems and functions due to the disagreement in supporting the transition process.

The stage necessitates strong fact-finding efforts, just like earlier stages. At this point, there should be a collection of essential data. It is also vital to remember that proper data gathering throughout implementation would be necessary to determine how viable the plan is. As a result, gathering data is a constant activity.

Monitoring and Assessment

The next step is determining if the equipment can comply with the specifications and achieve the objectives. The system evaluation step should take notice of some crucial operations. The initial steps stage involves the project’s goals being defined. Though increasing process output and cutting costs are the two main aims of operational yield optimization, other specific goals could be included under these two broad goals.

Consequently, its capacity to consider expected hazards should also be assessed. A crucial step in system development is risk assessment. It makes it easier to comprehend how the adopted approach may manage risk. It is essential to keep in mind that sometimes are other elements. The optimizing process proceeds without a hitch if the anticipated risks are reduced. It is crucial to consider and evaluate whether new hazards or difficulties can impede the company’s growth.

Conclusion

To be successful, operations involving yield optimization must go through many stages. The discovery stage, or data gathering, is the initial step and calls for people to compile information about the system’s operational procedures. The ideation stage of the second phase is when suggestions for developing a plan are produced. The third step, or implementation, is where concepts are put into practice in preparation for application. The observation and assessment stage is the last step, and its purpose is to determine how effectively the procedure works.

References

Basar, I. A., Liu, H., Carrere, H., Trably, E., & Eskicioglu, C. (2021). A review of key design and operational parameters to optimize and develop hydrothermal liquefaction of biomass for biorefinery applications. Green Chemistry, 23(4), 1404-1446. https://doi.org/10.1039/D0GC04092D

Han, J. K., Shin, B. S., & Choi, D. H. (2019). Using multivariate analysis and the quality-by-design approach, a comprehensive study of intermediate and critical quality attributes for process control of high-shear wet granulation. Pharmaceutics, 11(6), 252. https://doi.org/10.3390/pharmaceutics11060252

Ahmad, I., & Ahmad, S. B. (2019). The mediation effect of strategic planning on the relationship between business skills and firm’s performance: Evidence from medium enterprises in Punjab, Pakistan. Opción: Revista de Ciencias Humanas y Sociales, (24), 746-778. https://dialnet.unirioja.es/servlet/articulo?codigo=8155778

Liu, R. T., Bettis, A. H., & Burke, T. A. (2020). Characterizing the phenomenology of passive suicidal ideation: a systematic review and meta-analysis of its prevalence, psychiatric comorbidity, correlates, and comparisons with active suicidal ideation. Psychological medicine, 50(3), 367-383. https://www.cambridge.org/core/journals/psychological-medicine/article/abs/characterizing-the-phenomenology-of-passive-suicidal-ideation-a-systematic-review-and-metaanalysis-of-its-prevalence-psychiatric-comorbidity-correlates-and-comparisons-with-active-suicidal-ideation/C10077BC3C4AB641F5C425E94EF1F3C0

write

write