Introduction

The term “advanced analytics” is a specialized way of describing the use of highly sophisticated techniques and tools in analyzing large and complex datasets to reveal hidden patterns. It goes beyond the traditional analytics methods, as Kaisler et al. (2014) argue. It covers a broad area of competencies, such as machine learning, data mining, predictive analytics, text analytics, and optimization algorithms. Advanced analytics makes use of mathematical methods, computational algorithms and artificial intelligence to identify trends, correlations and anomalies in data, which will allow organizations to take advantage of data-driven decisions and to have an edge over their rivals (Kaisler et al.,2014). In contrast, predictive modelling represents a particular case of advanced analytics methodology where statistical algorithms, together with machine learning techniques, are used to build a predictive model that uses historical data to predict future outcomes (Junqué et al., 2013). These models perform statistical analysis of historical trends and relationships contained in the data, and such predictions are made about future occurrences or behaviours. Predictive modelling is applied in numerous arenas, such as finance, marketing, medical care, and manufacturing, to determine customers’ behaviour, expected demand, processes, and risk management. By using predictive modelling to its utmost, organizations can make more sophisticated business decisions, uncover new chances and improve their business outcomes.

Sophisticated analysis and predictive modelling are a vital component of procurement activities, as they enable organizations to make more rational decisions through the use of data. In the fast-changing and money-driven business world of today, where every cent is significant, data processing is the key to success and staying abreast with the competition. For instance, think about a retail firm that needs to replenish shelves with the proper inventory for ample sales. There would be no advanced analytics in this case, which is like shooting in the dark; thus, there is a risk of overstocking products which might not sell or understocking popular products, which would lead to the loss of sales opportunities. Using historical sales data and market trends can help forecast future demand with higher precision and thus allow the Company to have the exact proper inventory, thereby avoiding both excess inventory costs and lost sales (Junqué et al.,2013). Modern organizations that desire to compete in a fast-growing environment should base their decisions on data. See the whole production chain, for example, a company which wants to buy raw materials. It can utilize predictive modelling to analyze suppliers’ performance, market conditions, and external factors such as weather patterns and, therefore, negotiate for better prices and a stable supply chain (Kaiser et al.,2014). This preemptive approach has not only decreased the expenses but also reduced the risks that come with supply chain disruption.

Moreover, the most sophisticated ones can discover the underlying patterns and facets that human brains cannot observe by themselves. For example, a transport company could apply predictive analytics to real-time data, such as traffic flows and weather information, to optimize its routes, cutting down on fuel consumption and carbon emissions and improving delivery times. The function of advanced analytics and predictive modelling is to give organizations a platform to gather and consolidate data, which is then used to make informed decisions and thus lead to the better operation of the organization, reduced costs and improved performance. In the world of data in which we are presently living, the use of these tools is not just beneficial but also a vital condition for remaining prosperous and meeting the customers’ and markets’ evolving needs.

The Project’s primary goal is to address the issue of homelessness in our city. One of the objectives is to raise awareness about the problem among community members and policymakers.

Purpose: The subject of this study is to investigate the contribution of advanced analytics and predictive models in the procurement decision process. Through researching the issue, the study aims to introduce knowledge about how data is applied to make the procurement process more effective in terms of demand forecasting, inventory management, and cost reduction. Consequently, the aim is to show that the use of data-driven approaches in modern procurement practices is essential, which is the case, and to give insights into the benefits and disadvantages of the implementation of advanced analytics in procurement processes.

Objectives

- To examine the importance of advanced analytics and predictive modelling in procurement decision-making.

- To analyze how organizations utilize data for demand forecasting in Procurement and its impact on inventory management.

- To explore the role of predictive modelling in optimizing inventory levels and reducing procurement costs.

- To identify best practices and challenges associated with implementing advanced analytics in procurement processes.

- To provide recommendations for organizations looking to integrate predictive modelling into their procurement strategies effectively.

In Scope

The study is focused on the application of modern analytics and predictive modelling methods in purchasing and decision-making in particular. It covers the overview of methods, including machine learning and data mining activities, that are used to estimate demand, optimize inventory, and cut expenses. The research seeks to achieve this by examining how the data generated through various sources can be utilized for rational sourcing the companies. Moreover, it will list the most efficient practices and difficulties that occur when implementing advanced-level analytics in Procurement to be provided with the guidelines for productive integration. In general, the study intends to support the existing know-how on the ways data-driven marketing techniques are used in contemporary procurement processes.

Literature Review

II. Understanding Advanced Analytics and Predictive modelling in Procurement

In the procurement domain, advanced analytics is the high-end method and tool to be used for data analysis, for which massive data is gathered to produce valuable inferences and to make competent decisions. This involves using methods including machine learning, predictive modelling, and data mining from procurement-related information so as to identify functional patterns and trends. In the particular case of machine intelligence is a branch of artificial intelligence where systems are able to learn from data and improve themselves over time without being specifically programmed. Machine learning algorithms use historical purchasing data to expose patterns in supplier behaviour, demand fluctuations, and price trends when in Procurement (Sleimen, 2023). Having seen these patterns, companies can predict demand in advance, optimize the levels of inventory and make better agreements with suppliers. Next to predictive modelling, the primary technique of advanced analytics is the use of mathematical algorithms to generate forecasts of future outcomes based on existing data. In Procurement, predictive models can predetermine the potential risks of supply chain disruptions, lay down the future trends of the market, and determine future costs (Sleimen, 2023). As an illustration, a predictive model can review past supplier performance metrics and external conditions like geopolitical situations to understand the possibility of delayed delivery. This allows procurement professionals to proactively mitigate risks and ensure the uninterrupted flow of goods and services.

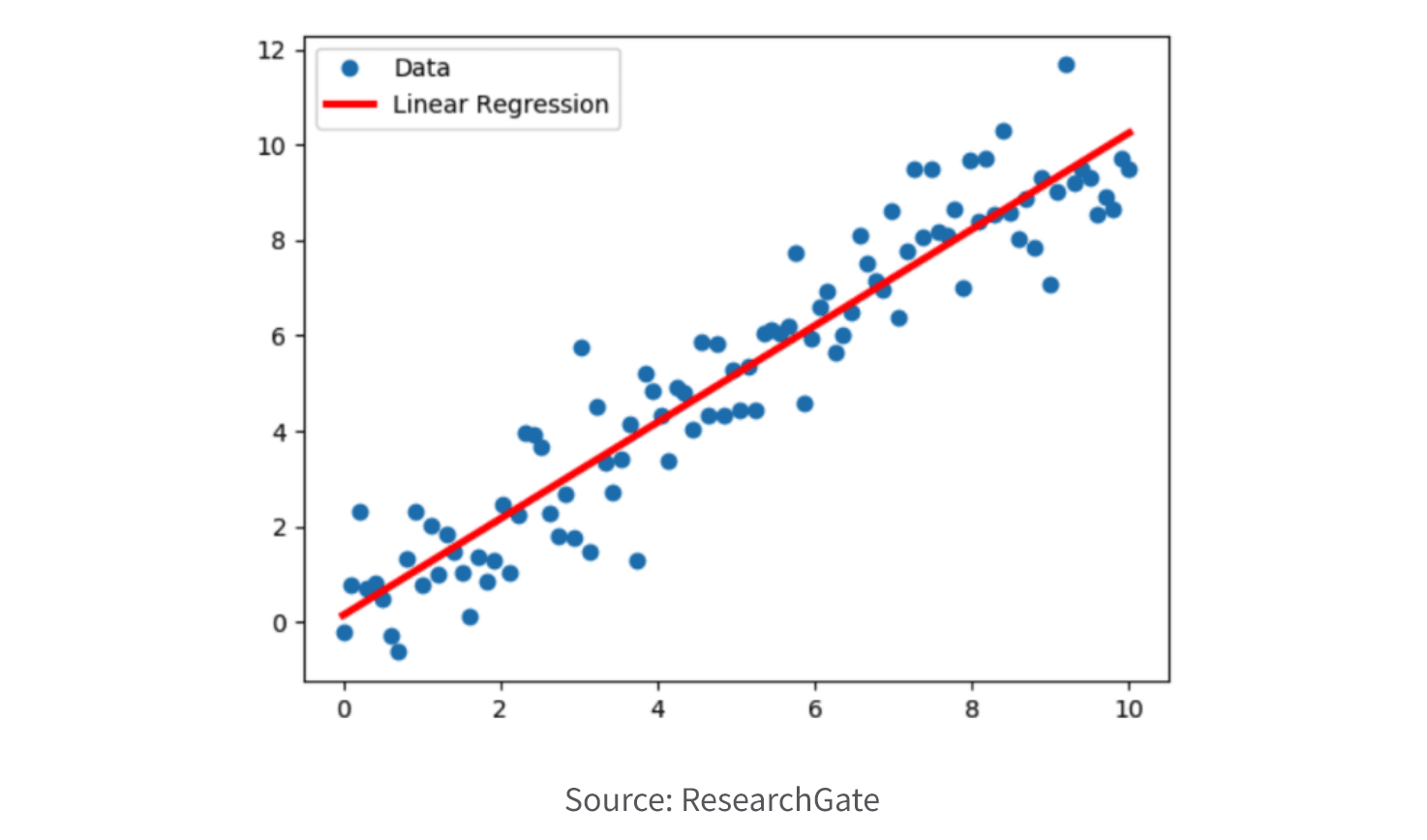

Data mining, as stated in the Qlik (n.d) publication, is concerned with extracting valuable information from large data sets by the identification of trends, associations and outliers. In the case of Procurement, data mining can be structured to analyze the supplier database, contracts of purchases and transactional files to detect hidden insights. For example, data mining algorithms can expose price differences among different vendors, detect instances of fraud and non-compliance, and optimize procurement processes for cost reduction and efficiency improvement. Let us make it more understandable: one best example is a regression form of data mining. Regression uses a relation of numeric or continuous variables towards a target variable to predict these values. The aim is to come up with a mathematical function or model which best fits the data and that employees can rely on to make the most precise forecasts of future trends for most companies (Qlik, 2022).

Figure 1.1 Regression data mining (Qlik, n.d)

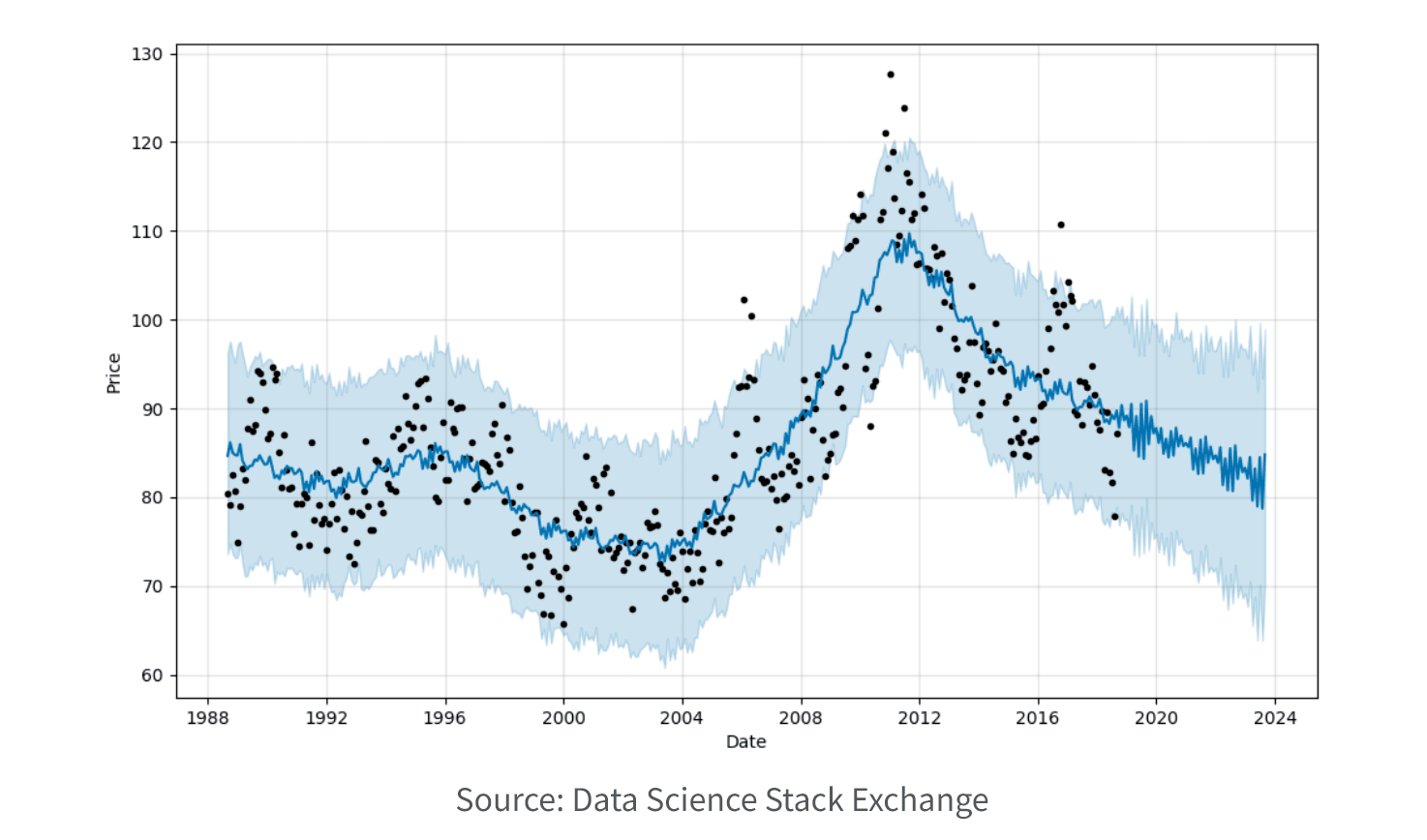

One of the established data mining and analysis methods is time series analysis, which aims at analyzing and predicting the data points collected repeatedly through time. It consists of forecasting methods, trending analysis, seasonality and anomaly detection. This takes place with the processing of time-dependent datasets (Qlik, n.d)

Figure 1.2 Time Series Analysis (Qlik, n.d)

For us to give a good example of Figures 1.1 and 1.2, we should consider a manufacturing company that leverages advanced analytics in its procurement processes. Using machine learning algorithms, the Company will be able to analyze historical purchasing data that will allow it to predict any fluctuations in demand for raw materials and customer behaviour or anticipate them and to be on the trend by checking on such data. This, in turn, will allow them to improve the levels of their inventory, minimizing the possibility of stockouts or an excessive stock of products. Furthermore, the predictive modelling approaches can anticipate the upcoming price movements of the raw materials with the help of market trends and supplier behaviour, which enables the Company to gain a competitive advantage by signing favourable contracts and minimizing procurement expenses (Junqué et al.,2014). Machine learning is one of the newest AI technologies, and it allows systems to learn from data and enhance themselves on their own without the need for extra programming. In Procurement, intelligent algorithms can be used to process historical purchasing data; this will help to identify the trends behind the suppliers, demand fluctuations and pricing irregularities. The identification of these trends enables enterprises to foresee forthcoming demand, bring inventory levels to the optimum, and come up with better contracts with suppliers. Analytical modelling is a key technique in advanced analytics, which is achieved through the application of mathematical algorithms to historical data with the aim of forecasting future outcomes (Roy et al.,2022). In Procurement, predictive models can estimate possible supply chain interruptions, identify market trends, and flag potential future costs. For instance, based on Roy et al. (2023), the forecast model uses past supplier performance data and external factors like geopolitical events to form predictions of possible delivery delays. This makes it easy for procurement professionals to be more proactive in risk avoidance and, therefore, maintain the flow of goods and services uninterrupted.

Scenarios Where Data Analytics Enhances Procurement

III. Demand Forecasting

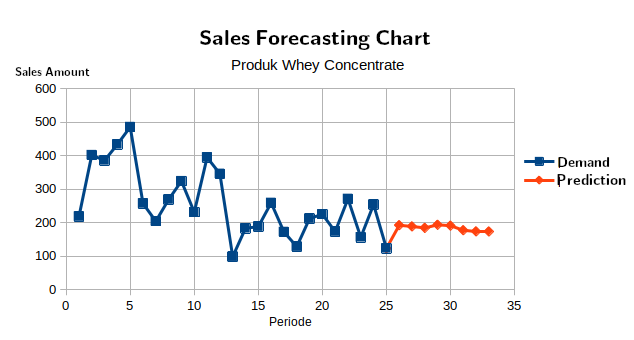

Precision in forecasting the demand is the key quality in Procurement as it allows organizations to manage their stock properly, order the goods most efficiently and make correct decisions. Accurate forecasting of future demand for goods and services would help organizations stock enough items at the proper time, preventing low sales and excess inventory costs. A great portion of the demand forecasting process is the use of historical data and predictive models. Historical data acts as a source of information about sales patterns in the past, customer behaviour and market trends, on which to basis future demand forecasting. Through historical sales data over different time periods, organizations can learn seasonal trends, cyclical patterns, fluctuations between different periods, and the other influences on demand variability. A good example of demand and forecasting is in Figure 1.3 below, which shows how predictive analysis fits in after observing any trends in the marketplace for most organizations.

Figure 1.3 (Fauzi et al.,2022)

Machine learning algorithms for this particular case analyze the data as it is being streamed, detecting patterns and correlations. The learning process from historical data and adaptability to the fluctuations in demand patterns it makes possible for the algorithms to be more accurate and responsive (Nalini, 2023). More straightforward examples like regression models, time series forecasting with neural networks, and ensemble methods are other instances. Predictive analytics, in this case, will depend on the calculation of statistical models and data mining to predict demand as it happens. It is based on current data flows and historical data that make it possible to derive insights and forecasts (Nalini, 2023). Predictive analytics may be used for various demand forecasting levels, which might include SKU-level forecasting, demand forecasting for special customer groups, e.g. the elderly, and demand forecasting for specific geographical regions. By bringing up predictive models, companies can curb their forecasting errors, enhance the accuracy of demand forecasts, and react better to the changing market. (Nalini, 2023). This enables procurement professionals to maximize their inventory stock levels, minimize stockouts, and free up their working capital. As a result, they can avoid extra inventory holding costs. Furthermore, proper demand forecasting helps an organization make better decisions about manufacturing planning, resource allocation, and negotiations with suppliers, which ultimately leads to the improvement of operational efficiency and cost savings.

Case Study: Walmart’s Demand Forecasting

Walmart, the global retail leader, is evolving through the implementation of advanced analytics and predictive modelling techniques right into its demand forecasting operations. Not just in the United States but also in numerous other countries, Walmart commands the attention of 245 million customers who visit their 10,900 stores and ten active websites every day. (ProjectPro, 2023) Whether it is online activities, such as social mentions or in-store purchases, Walmart has always been among the best retailers in the world (ProjectPro, 2023). Global Customer Insights estimate that Walmart gets observed in around 300,000 social mentions per week. The retailer employs approximately 2 million employees every year and hires over 500,000 employees every year. The number of associates with Walmart is even higher than some of the Company’s customer numbers (ProjectPro, 2023).

The store collects about $36 million per day from the 4300 US stores that it operates. The article covers how Walmart’s big data analytics is used to increase the Customer’s Emotional Intelligence Quotient and Employee’s Intelligence Quotient (ProjectPro, 2023). Walmart’s thousands of stores around the globe and large product range present a difficult time in forecasting consumer demand, which results in inefficient inventory management, insufficient stock levels, and overall operational inefficiency. The methodology of Walmart’s demand forecasting is based on the accumulation and study of a great deal of historical sales data, customer demographics and external factors, e.g., weather conditions and economic indicators. Walmart, which is also the largest retailer in the world, follows and identifies each person. With Walmart having access to as many as 145 million American customers, who generate up to 60% of the data from US adults, the Company possesses overwhelming data. Walmart monitors what customers purchase, where they live and what materials they like using the in-store Wi-Fi power (ProjectPro, 2023). The big data team at Walmart Labs looks at all the tastable actions on Walmart.com – what people buy in-store and online, what is trending on Twitter and how local events like the San Francisco Giant’s winning the World Series affect buying patterns. They also observe how local weather deviations influence purchasing habits (ProjectPro, 2023).

Consequently, all noted events are processed continuously by big data algorithms to find out who buys what, eventually supplying customers with a personalized shopping experience. Social Genome is a big data analytics solution which Walmart Labs create to analyze hundreds of thousands of Facebook messages, tweets, YouTube videos and blog postings from millions and billions of people (ProjectPro, 2023). Social Genome analytics solution helps Walmart attract customers’ friends who post and talk about Walmart’s products online to tell them about the product and the special offer they can get. Our Social Genome product uses publicly available data from the web and social media along with private data such as the individual’s contact information, email address, and customer purchasing data (ProjectPro, 2023). This data provides Walmart with the context of its users, and it helps it improve its analysis. This information helps to identify the trends, patterns, or even correlations that are used to develop accurate demand forecasting models.

The main initiative in the process of forecasting demand for Walmart is the use of machine learning algorithms (Shoushtari et al., 2021). These algorithms use recent sales data history and real-time information to incorporate these into the dynamic forecast adjustment. For instance, Walmart’s predictive model may project the shifts in customer behaviour during extreme weather conditions like hurricanes or snowstorms and balance the stocks accordingly (Shoushtari et al., 2021). Through the utilization of innovative methods, along with the continuous perfection of its forecasting capabilities, Walmart could receive a considerable increase in its demand forecasting accuracy. This facilitated the Company to have an optimum inventory level, minimize the excessive inventory holding cost, and bring about no stockouts (Shoushtari et al.,2021). Therefore, this has contributed to Walmart’s growth in terms of sales and operational efficiency and low cost of ownership for the customer.

On the other hand, one of Walmart’s biggest achievements in demand forecasting is its capability to involve predictive analytics in multiple sectors of the Company’s operation. To illustrate, Walmart uses demand forecasts for inventory management decisions. Thus, the products are available in the right quantities at the right time. (Shoushtari et al.,2021). Furthermore, Walmart makes use of demand forecasts for the purpose of improving the effectiveness of supply chain logistics functionality in order to enhance product flow and transportation efficiency. Beyond Walmart’s inventory management and distribution systems, the demand forecasting tools developed by the Company reach beyond traditional retail operations. The business takes the predictive analytics approach for anticipating demands of seasonal products, promotional items and new product launches (Shoushtari et al.,2021). With the help of precise forecasts for these commodities, Walmart can then allocate resources perfectly, attain better marketing strategies, and take advantage of sales opportunities.

Inventory Management

Inventory management as part of Procurement for companies is a complex task, and companies have to address the obstacles to achieve effective operations. This is because inventory management is the practice which includes all those activities that are arranged to make certain that consumers are served with the needed products or services. It helps outline the procurement and production activities to meet the demands of advertising and marketing as well as the desire of the organization to reach consumers (Gitau, 2016). First off, it is hard for companies to manage their stocks well, which can lead to either having too much inventory or needing more for sale. This may lead to higher holding costs for an empty inventory or lost sales because of a lack of stock at hand. Moreover, inventory management involving different locations or warehouses can lead to logistical challenges, which will hinder the ability to control and coordinate inventory delivery in a timely manner. To that end, market volatility and changes in demand patterns multiply management complexity, resulting in companies’ adjustment to uncertainty.

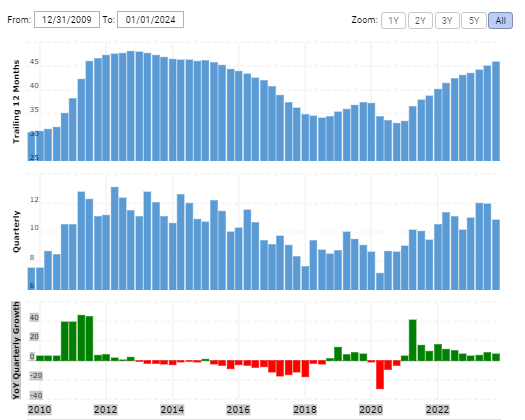

Using all these kinds of challenges, predictive analytics would be the most important tool to face these challenges and make the best decisions at inventory levels in Procurement. By using the tools of predictive analytics to analyze historical sales data, market trends, and other relevant factors, the algorithms can forecast future demand more precisely. Through this, companies can identify the rise and fall in demand and adjust their inventory levels to reduce the risk of stockouts or excess inventory (Macrotrends, 2023). Apart from forecasting demand, predictive analytics also helps pinpoint seasonal trends, lowering the inventory level to a level that meets the anticipated trend patterns. The Coca-Cola Company’s marketing strategy relies on the development of strong brand equity, coupled with marketing, research, and innovation based on predictive analysis; this works to give it a high market share in the non-alcoholic beverages industry in response to customer demand for healthier alternatives (Macrotrends, 2023). Items such as coffee, sparkling water and sports drinks are now offered as healthier options. From Coca-Cola Energy, Coca-Cola Plus Coffee, Powerade Ultra and Powerade Power Water to these additions, this is one of the many avenues. The portfolio of this Company includes drink products, which range from soft drinks to energy drinks. Beyond its signature glistening soft drinks, it also stocks an extensive assortment of still merchandise comprising water, enhanced water, juices and juice drinks, sports drinks, ready-made teas, coffees and dairy and energy drinks (Macrotrends, 2023). The Company, which is a market leader in this market, makes most of its beverages, sells them, and distributes them.

Figure 1.4

Such scattered evidence as the ones available from data analytics and predictive modelling are the ones that allow the Company to be profitable in long-term and, at the same time, avoid losses because most threats tend to be identified before they really do occur (Macrotrends, 2023). For example, consider looking at revenue from beverage drinks. In that case, Coca-Cola’s trajectory from 2000 to 2020 reflects a consistent upward curve that is dotted with increases in revenue year by year (Macrotrends, 2023). In 2023, the fourth quarter revenue achieved $10.849 bln after augmenting by 7.15 % on a year-on-year view. The gross income in 2023 will be $45.754 billion, and it will increase by 6.39% from the previous year. The Company’s yearly income has recorded a positive expansion for the past few years. With a 2022 income of roughly $43.004 billion and 11.25% growth from the previous year, (Macrotrends, 2023) is considered a remarkable figure. Last year, 2021, brought us an impressive year-on-year turnover increase as we earned $38.655 billion, which is actually -17.09% more than we had a year ago. In this way, the numbers stress the fact that Coca-Cola’s sales volumes are stable and stipulate that the Company never ceases to increase earnings.

As one of the businesses that are becoming focused on data-driven and AI-based AI and the provision of strategic decisions for its Procurement, Coca-Cola is still catching up when it comes to innovation. It was one of the first companies to launch the innovative freestyle fountain machine and also works on engaging the customers more deeply than just marketing to them. In conclusion, in procuring the given, the problems arising while running the inventory may include keeping the desired level of inventories, having it balanced evenly among the several facilities and, of course, the risk of fluctuation in demand. Nevertheless, predictive analytics, as a solution, proves to be a powerful tool in this sense because it helps organizations evaluate demand more precisely and sets inventory levels at the right pace. Amazon, Walmart and Coca-Cola, which apply data analytical tools to purchasing these days, serve as examples of how the gathering and analysis of business information significantly improves inventory management (Ulunma, 2020). By utilizing predictive analysis tools judiciously, organizations can shorten upcoming conditions in procurement processes and thus help them comprehend these situations more resourcefully in the course of business processes.

V. Cost Optimization

The aspect of Procurement that is concerned with cost allocation is referred to as cost optimization. It is the art of making wise decisions on sourcing all the goods and services that are needed at a minimal cost. Among the responsibilities that entail is bargaining for the best terms with suppliers in matters such as smooth Procurement and spotting any opportunities in this area from in-house data analytics. The ability to make efficiency savings through procurement costs can provide organizations with the competitive edge they need to make more profits, improve their competitiveness and drive value in their supply chain processes. Cost optimization in Procurement is significant as it directly impacts a company’s ability to compete and eventually earn profitability. (Munir et al.,2023) The procurement department is traditionally responsible for finding competitively priced goods and services while still ensuring adherence to quality standards. Conspicuous cost reduction approaches allow organizations to obtain the most effective cost efficiency, reduce expenditures, and, at the same time, boost their bottom line (Munir, 2023). Implementation of a cost-effective procurement system is non-negotiable.

The procurement expenditures for a company sum up a major part of the Company’s costs, with an even more profound impact on the businesses whose input comes from raw materials or outsourcing services. Through the right procurement management, organizations can improve their financial health, increase profit margins, and, as much as possible, use the resources efficiently (Wrike Team, 2023). Apart from that, the competitive scenario gives a strategic advantage along with cost optimization through which organizations can provide competitive prices to customers while still making a profit. In such a situation, the cost advantage is created by the side of the organization and the ability of its managers to produce goods or services at a lower cost than competitors while maintaining decent quality. (Made Up Team, 2023) This delivers businesses the goods to sell at prices lower than their competitors but still make profits, take orders from price-sensitive buyers, and finally grab the market. Gaining Competing with competitors on a low-cost basis is mostly done by a well-developed operating system, using best practices, and effective cost controlling.

Cost management and saving opportunities in Procurement can be accurately determined with the assistance of predictive modelling. The models fed by predictive analogies use past data, market details, and other prospected elements to predict future costs and recognize those places where the cost can be reduced. For example, a company can use a predictive model to analyze supplier performance data in order to find chances to renegotiate the contract together with the business partner being able to propose building up better acquisition of raw materials on more lucrative terms (e.g. volume discounts or lower pricing) (Wang et al.,2016). Preventive measures, such as identifying spending reduction opportunities, serve as enabling factors for organizations to formulate proactive tactics that impact procurement expenses and, hence, the cost competitiveness of businesses. Moreover, through predictive modelling, organizations have the possibility of enhancing the effectiveness of their strategic sourcing and recognizing alternative suppliers or outsourcing locations that provide better costs (Wang et al., 2016). The evaluation of these parameters, which include transport costs, delivery lead times, and reliable supply median, is sufficient for the management to make data-driven judgments with the aim of saving operational expenses without very much sacrificing quality. This points out that predictive modelling may also enable the organization to discover the existing inefficiencies in its procurement process, consequently, such as maverick spending or duplicate approvals. Through implementation and adjustments, there is also a chance to improve its current situation, and eventually, the process becomes streamlined (Grennan & Swanson, 2020). For instance, the study report focused on procurement problems, priorities, and needs addressing; supplier attributes and assessments; procurement trends, particularly on environmental, social responsibility, and technology aspects; and also differences related to industries, regional or country segments. As the Wrike Team points out, the quotes cited in this report are drawn exclusively from their thought leadership interviews with no less than five executives who are in charge of Procurement; these executives are based in the United States, the United Kingdom, and other countries; their industries are diverse; and the quotes and views given by them add up to what the Amazon Business executives are saying.

VI. Data Governance and Privacy In Procurement

In spite of having a passion for gathering and analyzing information from all sources, e.g. customers, suppliers and past windows whenever offering products, it is also important to protect this data from breaches or hackers in any way. Data governance and security are part of the procurement analytics framework that the organization follows to ensure that they have control of the data and, concurrently, the citizens’ right to privacy is protected. In the modern data–driven world, organizations need to be ubiquitously knowledgeable about the multiple factors favouring data governance and maintenance of privacy standards. This is primarily done through the clean creation of data management policies and procedures in procurement analytics (Tene & Polonetsky, 2012). Among responsible measures of data management are defining roles and functions, standing on top of data quality standards, and proceeding with the process of data access and usage (Tene & Polonetsky, 2012). Data governance standardization serves as the foundation of the practices that make data processes consistent, transparent, and accountable.

In addition to that, the need to ensure privacy in procurement analytics with respect to organizations adopting the necessary precautions to protect sensitive data is integral. This involves the allocation of sensitive personal information, encrypting information during transmission and storage, and restricting access to databases to authorized personnel only (Tene & Polonetsky, 2012). By enhancing privacy protections, businesses can maintain trust and credibility with stakeholders and preclude data leakage, which, in turn, lessens the likelihood of hacking or unauthorized access. Additionally, having to conform to legislations like the General Data Protection Regulation (GDPR) and the California Consumer Privacy Act (CCPA) when applying analytics is another aspect that needs to be well taken care of. These regulations mean that organizations are subject to stringent specifications regarding gathering, storing and processing of personal information while Europea (2023). Organizations need to make sure their entire data-securing system complies with these rules, including obtaining data collection permission, developing control systems over personal data and supplying mechanisms for data portability and erasure (Alexe, Sandru, 2020). In addition, data integrity and security should be taken into account because they play a massive role in the confidence, consistency, and confidentiality of procurement data. Organizations can apply different ways to preserve the implementation of data integrity and security, including data validation checks, systems access controls and audit trails, and frequent assessments and audits (Alexe & Sandru, 2020). Through a deliberate approach to addressing those factors that could cause data leaks and the vulnerability of procurement data, organizations can significantly reduce the risks and keep the integrity and confidentiality of the procurement data secure.

VIII. Trending Insight Analytics and Predictive Modeling That Can Be Used by Buyers to OptimiOptimize Operations Fully

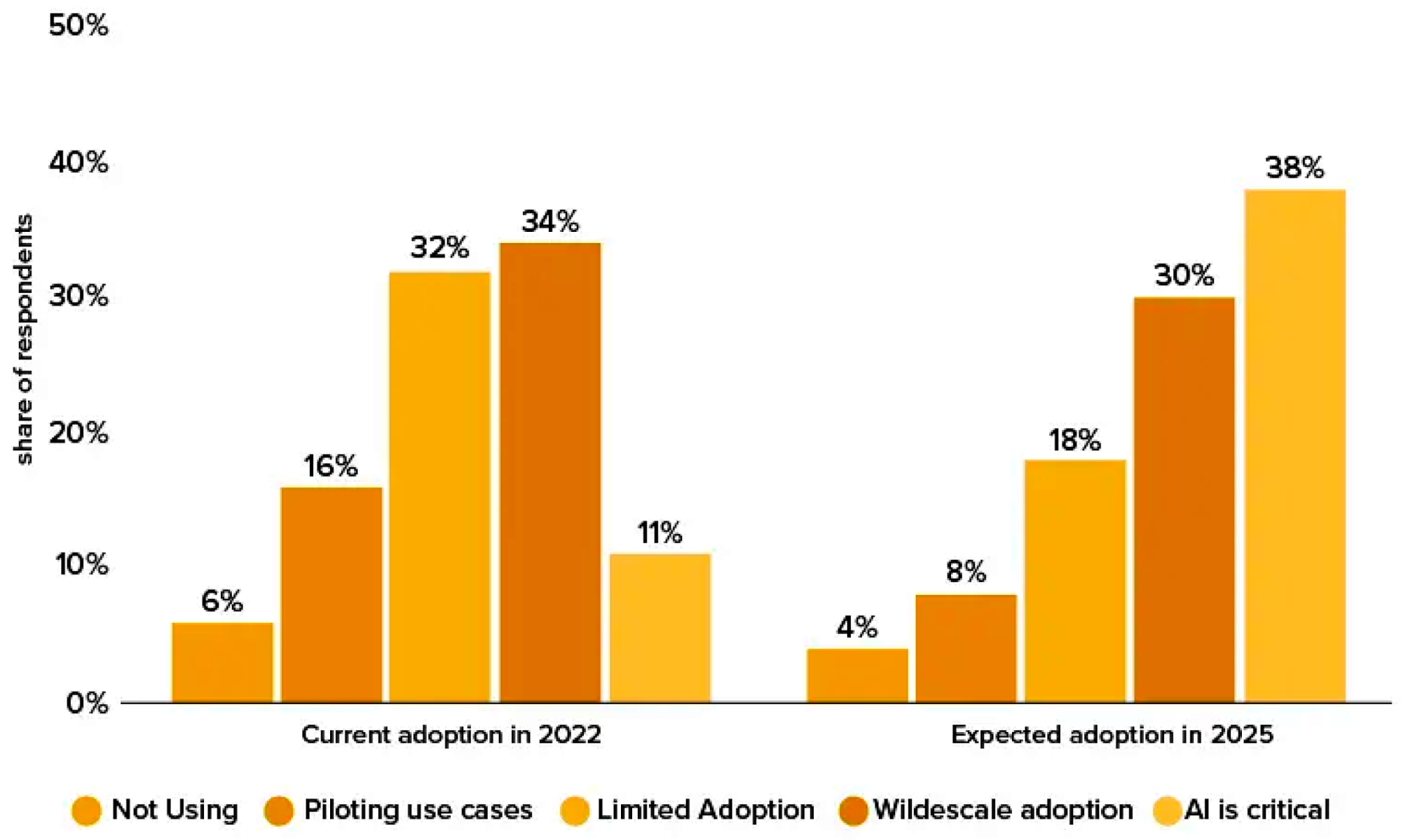

Forecasts in higher analytics and predictive modelling fields within procurements would bring positive and significant chances for both the organizations and their employees who are working in Procurement. The adoption of AI and machine learning AI techniques is another example of modern trends in procurement analytics. These technologies help companies create a platform on which they can evaluate large datasets more accurately, identify trends, and do proper forecasting (Taykar, 2024). Indeed, AI could be applied to assist predictive analytics with better accuracy as they foresee demand, optimize holdings better and locate cost-reducing opportunities. (Taykar, 2024)

What is more, some SRM strategies now leverage predictive analytics applications in their processes. Through data analysis concerning customer performance, market trends as well and external matters, organizations can get more thorough information regarding suppliers’ performance. They can thus make more inquisitive decisions concerning supplier selection, contract signing as well and supplier risk management (Taykar, 2024). Thus, they will ensure smooth cooperation with suppliers, reduce risks in the supply chains, and enhance efficiency across the supply chain means.

Figure 1.5 (Aljohani, 2023)

Figure 1.5 depicts the use of artificial intelligence to map the intelligence of the business and let the system decide what is going to happen to the business in the future. Effective utilization of predictive analytics and machine learning is one of the crucial aspects of the conduct of this study, as the technology can potentially bring a far-reaching change in the area of supply chain risk management (Alijohani, 2023). Today, organizations benefit from these advanced methods of risk management. A risk becomes identifiable and mitigated early on with the real-time approach to risk, reducing the need for emergency, which was the only way before this. Organizations are able to ascertain optimal resource usage, boost operational stability, and improve the satisfaction of their clients by employing predictive analytics, historical data, and machine learning techniques in the current dynamic business environment (Alijohany, 2023). Such deep integration is critical for rising supply chains’ agility as well as resilience in the globalized business environment with the aim of mitigating disruptions and continuing market share stability.

Another procurement area that has become increasingly important in working with predictive analytics is sustainability, as well as ethical sourcing. Organizations are rapidly adopting such approaches to try to check raw material provenance, partake in suppliers’ behaviour in line with environmental and social principles, and locate sustainable sources. Such an approach discourages deforestation, assists oceanic pollution, and hence strengthens the business’s corporate social responsibility performance. From now on, keeness is to know how the field will evolve due to the continuous progress in advanced analytics and predictive modelling, which can actually change procurement procedures completely. IoT devices and sensors utilizing predictive analytics techniques is a segment of research that is of great interest to me as a supply chain manager. Collecting actual-time data on inventory fullness, transportation courses, storage environment, and conditions can help companies keep track of the supply chain, increase visibility and transparency, optimize logistics processes, and improve procurement decision-making.

Conclusion

In conclusion, the present Project has helped to see the crucial role of the use of advanced analytics and predictive models for procurement decision-making processes. With the consideration of the different branches, which are demand forecasting, inventory management, cost optimization, data governance, and future trends, as a result thereof a number of key findings and insights have been found. First of all, sophisticated data analytics processes, such as machine learning, predictive analysis, and data mining, make it possible to explore numerous data sources and extract useful information that goes beyond traditional data analysis techniques. By benefiting from records and prediction models, organizations can then effectively plan for demand and find lost money, which determines how the costs of the organizations will be affected and also the operational efficiency.

The role of the future of procurement modernization practices must be considered. The modern and dynamic business environment makes the necessity of being data-oriented vital for organizations so they may remain adaptive, receptive, and competitive. Utilizing the tremendous potential of data analytics, firms may achieve superiority over competitors, cost savings, risk mitigation, and enhancement of coordination throughout the entire complex of the operation. Glancing forward, the future of data-powered buying processes is very positive. Rapid technological advancements, including artificial intelligence, the Internet of Things, and data visualization, lead to new procurement practices that can deliver the ultimate Diligent Buyer experience. Even by adopting new technologies, pursuing the latest findings, and investing in resources and people, companies can get a new perspective, improve operational processes and achieve continuous progress in regard to procurement operations.

References

Alexe, I., & Sandru, D. M. (2020). Data Protection in the Public Procurement Process. Eur. JL & Pub. Admin., 7, 224.

Aljohani, A. (2023, October 20). Predictive analytics and machine learning for real-time supply chain risk mitigation and agility. MDPI. https://www.mdpi.com/2071-1050/15/20/15088

Europeia, U. (2023). General Data Protection Regulation (GDPR). Regulation (EU) 2016/679 of the European Parliament and of the Council, p. 27.

Gitau, R. W. (2016). Inventory Management Practices and Organizational Productivity in Parastatals in Kenya (Doctoral dissertation, University of Nairobi).

Grennan, M., & Swanson, A. (2020). Transparency and negotiated prices: The value of information in hospital-supplier bargaining. Journal of Political Economy, 128(4), 1234–1268.

Junqué de Fortuny, E., Martens, D., & Provost, F. (2013). Predictive modelling with big data: Is bigger really better? Big data, 1(4), 215-226.

Kaisler, S. H., Espinosa, J. A., Armour, F., & Money, W. H. (2014, January). Advanced Analytics–Issues and Challenges in a Global Environment. In 2014 47th Hawaii International Conference on System Sciences (pp. 729–738). IEEE.

Macrotrends. (2023). CocaCola revenue 2010-2023: KO. https://www.macrotrends.net/stocks/charts/KO/cocacola/revenue

Munir, I., Mahmood, K., Shafqat, Z., & Ghaffar, M. (2023). Procurement 4.0 and Sustainable Supply Chain Performance: The Mediating Role of Procurement Process Optimization (PPO). Pakistan Journal of Humanities and Social Sciences, 11(4), 4151-4169.

Fauzi, Arma & D. P., Bambang & Makhrus, Faizal & Andriyani, Widyastuti. (2022). Price Intelligence Using K-Means Clustering and Linear Regression, Case Study of Store Dk Nutritionindo at Tokopedia. 10.26798/jiss.v1l1.602.

ProjectPro. (2023). How has big data analysis helped increase Walmart’s sales turnover? https://www.projectpro.io/article/how-big-data-analysis-helped-increase-walmarts-sales-turnover/109

Roy, D., Srivastava, R., Jat, M., & Karaca, M. S. (2022). A complete overview of analytics techniques: descriptive, predictive, and prescriptive. Decision intelligence analytics and the implementation of strategic business management, 15-30.

Sleimen M. (2023). What are procurement analytics? Program. https://www.tradogram.com/blog/procurement-analytics#:~:text=Predictive%20Analytics%20in%20Procurement&text=By%20analyzing%20historical%20data%2C%20businesses,and%20make%20accurate%20procurement%20forecasts.

Shoushtari, F., Ghafourian, E., & Talebi, M. (2021). We are improving Performance of Supply Chain by Applying Artificial Intelligence. International journal of industrial engineering and operational research, 3(1), 14-23. Takyar, A. (2024, March 13). Ai in demand forecasting: An overview. LeewayHertz. https://www.leewayhertz.com/ai-in-demand-forecasting/#:~:text=AI%20algorithms%20analyze%20sales%20data,reducing%20excess%20inventory%20carrying%20costs.

Tene, O., & Polonetsky, J. (2012). Big data for all: Privacy and user control in the age of analytics. Nw. J. Tech. & Intell. Prop., 11, 239.

write

write