Drilling engineering is a discipline of petroleum engineering that is concerned with the use of various tools and techniques to extract various types of wells to get access to oil reservoirs. It entails intense missions related to the exploration of water, oil or gas components from the underground reservoirs. This field is further classified into four other engineering professions that include completion engineering, operational engineering, production engineering and reservoir engineering. This topic is important in the field of petroleum mining because it determines the cost of oil mining and production process. It is designed to convert theory into practice by relating many of the ideas known in theory to practical solutions. It delivers the appropriate research materials and emerging technologies to enhance the drilling process. This research paper provides an overview of the drilling exercise for purposes of helping the general population to understand the mechanics behind the process. It covers the principles of drilling, the drilling fluids and some of the common drilling problems.

The petroleum sector has been serving and continues to act as the backbone of the energy sector in the modern world and hence a driver of modern civilization. Whereas most people are only conversant with the drilling of petroleum wells, the exercise dates back to the dawn of human civilization. Traditionally, people drilled wells to access water for drinking and other domestic uses. In this regard, wells provided the best source for drinking water as the water obtained had plenty of minerals that were excellent for the body. Later people began extracting fossil fuel, which they utilized in its natural state. However, today, as the technology continues to advance, engineers and researchers have developed more effective and efficient techniques to access and extract the fossil fuels, a process known as drilling. This topic is of great importance in the modern study of sustainable oil and gas development strategies. There is a need to formulate more environmentally friendly mining techniques that will conserve the ecology.

Principles of Oil Well Drilling

The drilling process is characterized by an interaction with rocks and other earth components. Therefore, a successful drilling process requires one to understand the character and attitude of the rocks and also the manipulation of the tools. The most common objective of drilling is to obtain oil, water, or gas. Consequently, it is important to assess the principles of the oil drilling by considering some of the important determinants of the drilling processes, such as the structure of the earth. This understanding helps miners to properly select sites with favorable rock formations towards the mining process.

Structure and Character

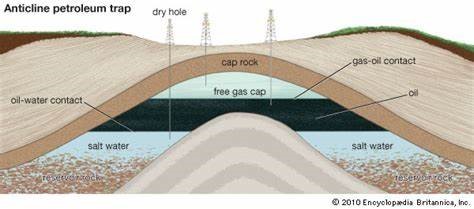

Oil and gas mainly occur in sedimentary rocks, which is characterized by shales and sandstones. Their origin is attributed to the gradual decomposition and distillation of organic matter. These materials can rarely penetrate the sedimentary rocks and get into the plutonic rocks. These sedimentary rocks occur in rock structures that are known as anticlines, which are characterized by upward, archlike folds of the rocks as shown in the figure below.

Oil and gas are naturally occurring hydrocarbons, which implies that they are made up of two important elements: hydrogen and carbon. Because of the strong attraction between hydrogen and carbon, the product of this combination results in different compounds (Dutta et al., 590). Thus, the oil processing and refinery processes mainly focus on refining the hydrocarbons recovered from the era to develop other products including liquefied petroleum gas, natural gas, kerosene, diesel fuel, and gasoline. Besides, the hydrocarbon products obtained are also essential towards development of other synthetic materials including nylon and plastics. While the crude oil and the natural gas exist in layers of rocks, they occasionally sip out of these rocks onto the surface. However, this process is not common because the rock surfaces above the sedimentary rocks holding the gas is mostly impermeable and will not allow oil and gas to flow to the surface.

The formation

The earth surface holds different types of materials, both organic and inorganic. The organic materials, which mainly comprises plant and animal matter, decompose over time as they are subjected to temperature and pressure. Oil is generated from the remains of microscopic animals and plants that died numerous years ago, between ten million to six hundred million years ago, as these materials travel down the ground. Once an organism dies, it begins decaying. The process takes several years, in which the microbes begin decomposing the materials. The decomposed material continues to be exposed to the natural conditions of high temperatures and pressures, disintegrating further and getting incorporated into the soil particles. The resulting materials are sediments characterized by a fine-grained shale, also called a source rock. The geological processes also take place, where the materials sink further down the earth, forming layers in what becomes sedimentary rocks.

Oil Drilling Techniques

Oil and gas exploration can be done in a variety of ways. Cable drilling or percussion, electro-drilling, rotary drilling, directional drilling and dual-wall reverse-circulation drilling, are the five common prevalent (Funnell). The technique to be employed depends on a variety of factors, including the kind of formations, geographical region, and soil composition, among others.

Cable Drilling OR Percussion

Percussion drilling is a typical manual drilling technique that involves attaching a pounding bit to a long cable and lowering it into an open hole. Because of the lengthy cable, and in this scenario, the driller supports the tools using a tripod, the method is also termed as cable drilling. The driller then repeatedly moves the hammering bit back and forth, loosening the soil in the borehole and then extracting it using a bailer. The bit is then removed occasionally, during which the cuttings are suspended in water. The water is pumped to the surface to remove these cuttings. The hole is supported by a steel casing, which prevents it from curving inside and also prevents the hole from being contaminated by the ground water. A permanent screen plus casing is fitted after some time, and the temporary one is removed. Drilling in consolidated and unconsolidated strata, including silt, sand, gravel, and sandstone, is possible using this method (Funnel). The method can be used to drill holes that are approximately twenty-five meters deep. An image of the drilling approach is shown below.

Source World Environment Library

Rotary Drilling

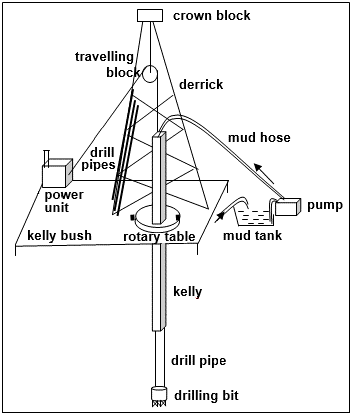

One of the most used drilling procedures is rotary drilling, and it mostly entails the digging of wells. This method is more applicable in exploring depths that are more than give miles below the ground. The technique involves the use of lightweight drills in drilling low-depth wells on land. The exploratory wells are next drilled with different sizes of floating drills and rotary mobile. The approach is frequently employed to create a large inspection borehole or to gather representative rock samples. It entails mounting a motorized rotary cutting head on the tip of a shaft that revolves into the surface. It needs lubricating in order to keep the cutting head cold. This instrument is seen in the figure below.

The device is installed on a pedestal with a spinning table as well as a forty-meters-high derrick, as well as an injector pump, mud mixer, and a convenient engine. A twenty-seven-meter-long pipe, and a winch piece are among the equipment. The drilling pipe is attached to a square Kelly, and the rotating table directs it. A mud swibel is attached to the pipe and is linked to blowout suppressants. The drill is comprised of sharp cutting edges, also known as rolling cutters that are characterized by powerful teeth, and drag bits, and the pipe rotates at a speed of forty to two hundred and fifty revolutions per minute. Fluid circulation then aids in the removal of cuttings that have made their way into the pipe. When the driller uses air-based liquids instead of water-based liquids, the penetration rate increases. In cases where the drilling exercise entails penetration of unconsolidated sediments, a drag bit is more useful. On the contrary, the roller bit can be helpful in drilling through consolidated rock. Depending on how hard the formation material is, the drill’s total rotational speed can be increased or decreased.

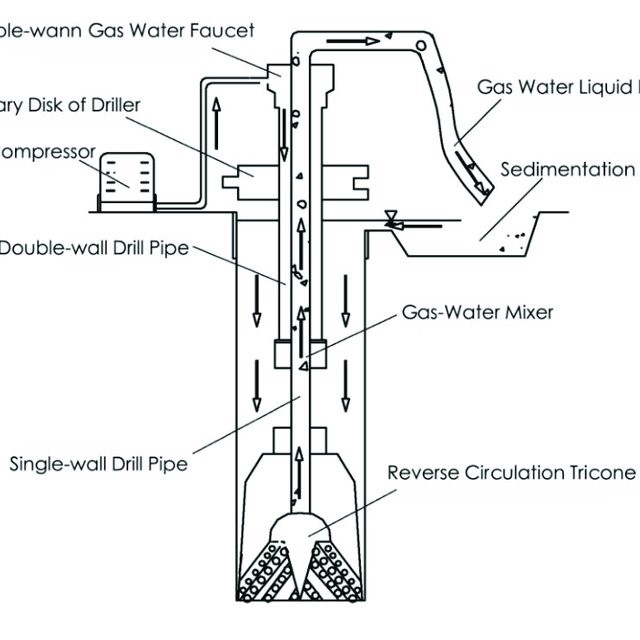

Dual-Wall Reverse-Circulation

Two central drill pipes that provide a regulated flow characterize this method of rotary drilling. Drilling fluid is pushed via a swivel on the exterior of the bit until it reaches the bottom, where it deflects upwards into the main duct. To assure a constant water sample, and return of formation the approach employs a flush-threaded double-wall drill pope and high-pressure air. The primary benefit of this method is that the trimmings and formation fluids are not polluted by drilling chemicals or combined with other borehole materials. The logging procedure is more reliable thanks to its up-hole velocity of about seventy feet per second. The samples of the specific strata where the drilling is taking place is then airlifted or bailed to the surface. The technique is more effective for geologic sample collection, in which case the samples are delivered via the cyclone that is formed at the ground. This approach is harmonious with both percussion drilling and rotary drilling techniques. The process cycles the liquids in a contained way, allowing for the recovery of all cuts at any moment. Another advantage with the technique is that it does not require surface casing. Furthermore, the approach is linked to high sample recoveries and enables for speedier penetrating in fissured or alluvial rock. It is also useful for getting a more precise estimate of aquiver production from the formation’s depths. The image of the technique is shown below.

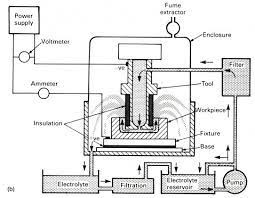

Electro-drilling

This technique should be perceived as a commercial drilling alternative to other popular techniques, such as the rotary motor system. It is more effective in penetrating earth formations and rock structures. It utilizes electric arcs to penetrate the desired structure. Besides, it is popular for utilizing circulating fluids to clear the arc area and sweep away the cuttings. The method uses fluid circulation to withdraw molten, electrically drilled material from the wellbore. In addition, it is known to utilize electrical arc cutting techniques with air blowing or water supply means connected to concurrently heat and cool the rock surface and facilitate its disintegration. The method is comparable to the classical flame blast, gas flame, or burner drilling approach. It is also known to utilize gas blast and a cooling medium against a rock face, which ensures that the rocks disintegrate by thermal shock. After the rocks have disintegrated, the liquids are circulated to carry cuttings and spallings out of the way of the cutting operation. The slag formed by the drilling blast is broken up using mechanical means with the flame blast drilling.

Directional drilling

This approach is an expansion of the rotary drilling technology, and works by directing the drill along a curved route as the hole deepens. The method is useful for oil explorers as it helps them to reach the depths that cannot be reached using vertical drilling. The major motivation for employing this technology is to save money since it allows you to create multiple boreholes in all directions from a unified platform. The technology also enables the driller to get accessibility to subsea reserves by utilizing computer systems as guides, and without the need to connect and disconnect sections. The method, which is also called directional boring, is preferred in the gas and oil mining industry because it increases the efficiency of the process and can also reduce the environmental impact of the drilling process. In most cases, the oil wells are located above the targeted reservoir. Consequently, accessing them requires vertical drilling to the well below. Consequently, while the rest of the drilling exercises entail vertical drilling, directional drilling involves drilling at a non-vertical angle. Therefore, directional drilling refers to any drilling process that is not vertical (Islam & Enamul 179). Its ability to allow the explorers explore various oil reserves without the need to drill many holes makes it more preferable and recommended by environmentalists.

Challenges of Drilling Engineering

Even in very carefully planned events, problems are always likely to happen. For example, even in instances where similar drilling practices are practices, since no two formations are homogenous, each of the two projects is likely to have different conditions, that make it different to different geological conditions. Consequently, there are various types of drilling challenges as covered below.

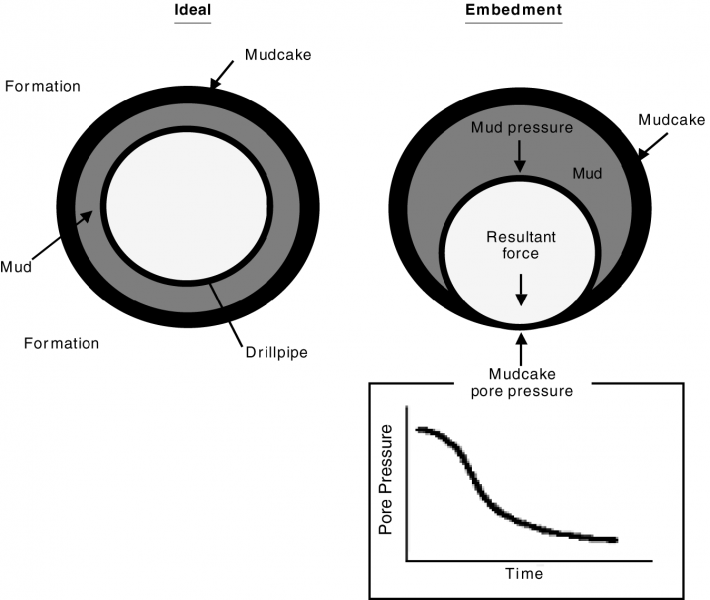

Pipe Sticking

The drilling exercise involves sticking a pipe inside the ground to access the minerals. A stuck pople occurs when this pipe gets stuck within the rock surface, making it difficult to obtain if back without breaking it. Such occurrences may be highly costly, accounting for around fifty percent of the overall cost of the well. Well-control and lost-circulation valves, which are a substantial concern in high-angle and horizontal wells, are frequently related with stopped pipes. This issue arises from the common practice of drilling in areas or regions where the annulus pressure surpasses that of the formation, potentially causing drill string failure. The easiest way to deal with this issue is to correctly regulate the lubricity of the drilling fluid as well as the filter cake purity throughout the formations.

Lost Circulation

Another problem associated with drilling mining is lost circulation, which refers to the process by which mud flows uncontrollably into a formation. This section is sometimes known as the “thief zone”, which results into what is called blind drilling if the drilling process continues during this lost circulation. This predicament arises from a variety of factors, including naturally fractured rocks, inappropriate drilling circumstances, and artificial breaks caused by high downhole pressure. Zones of lost circulation might be either partial or entire, depending on the situation. With partially lost circulation, mud keeps flowing to the level, causing some damage to the underlying geological structure. In contrast, total lost circulation happens when all of the mud is carried away into a mound and does not appear again. Blind drilling is the term used to describe drilling that occurs during a period of absolute loss of circulation. In the industry, this is not a normal protocol unless all of the minimum guidelines are satisfied, which are; The creation above the thief zone is dimensionally strong, there is no creation, the liquid is clear water, and it is financially effective and acceptable to drill in this formation.

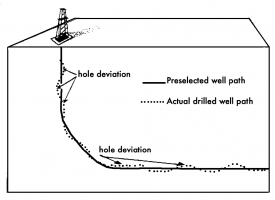

Hole Deviation

The inadvertent deviation of the drill bit from a predetermined borehole trajectory is referred to as this hole deviation. Whether the procedure includes drilling a linear portion or a curved-hole portion, the bit has a propensity to meander off from the targeted route, which can result in drilling obstacles such as greater drilling expenditures and legal issues with loose boundaries. An example of a hole deviation is as shown in the diagram below.

Although the actual reason for a bit diverting from its intended section is yet unknown, there are several possibilities. According to the researchers, the varied nature of the formation dip angle, drill string characteristics, stabilizers, installed weight on bit, and the hole’s inclination angle from vertical are all elements that contribute to the disagreement between the two measurements.

Pipe Failures

Another notable problem in drilling engineering is drill pipe failures. Twist off induced by extreme torque, splitting generated by severe tension, bursting or collapsing caused by extreme internal or external pressure, or fatigue due to the mechanical cyclic loads happening with or without corrosion are all examples of the issue. While it is impossible to totally eliminate the problem, there are some measures that one can take to minimize it. For example, by limiting generated cyclic loads and maintaining a non-corrosive condition throughout drilling sessions, fatigue failures can be reduced. Managing dogleg severity as well as drill string vibrations, on the other hand, can help to reduce cycle loads. In the existence of H2S, corrosion can be avoided by using corrosive scavengers or stabilizing the of the mud. To avoid drill string malfunctions, it’s also critical to handle and examine the drill string properly.

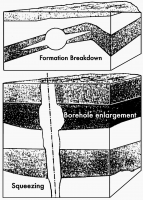

Borehole Instability

This procedure describes an unpleasant condition in which an open hole interval loses its gauge size, form, or structural stability. Mechanical fault due from in-situ strains, erosion originating from fluid flow, as well as chemicals arising from borehole fluid contact with the formation are some of the sources of this instability. Borehole instabilities can manifest themselves in a variety of ways, including hole closures or downsizing, hole expansion, fracture, and collapsing. The graphic below depicts the several types of hole instability problems.

The mechanical rock-failure may happen if the pressures exerted on the rocks surpass the tensile or the compressive strength of the rocks. Compressive failures arise from shear pressures arising from poor mud weight, while tensile failure occurs from normal stresses which originate from high mud weight.

Mud Contamination

Mud contamination is also a common drilling problem that occurs when the mud where the drilling process is taking place gets contaminated with foreign material and leads to undesirable changes in the characteristics of the mud. It may change the mud density, its viscosity, and filtration. The most susceptible mud systems towards contamination are the water-based mud system and one of the notable causes of this form of contamination is the overtreatment of the mud system with additives. Besides, this contamination may result from the material that enters the mud during the drilling process. Some of the most common sources of the contaminants include gypsum, soluble sulfides, soluble bicarbonates and carbonates, salt, and cement or lime.

Formation damage

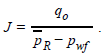

The term “formation damage” refers to the invisible being harmed by the unavoidable, resulting in an unidentified lowering in the unmeasurable. The procedure, in a different situation, pertains the damage to the reservoir caused by wellbore liquids used in the drilling and workover procedures. It refers to a zone of decreased permeability near the wellbore (skin) caused by foreign-fluid attack into the reservoir rock. Therefore, the overall definition of the process is the unintentional impedance to the flow of fluids into and out of a wellbore. A drop in permeability with in near-wellbore area, wide variations porosity to the hydrocarbon’s phases, and unanticipated flow constraints in the completion phase are all examples of flow restrictions that fall within this wide description. For the reasons that, while they may end up causing flow obstructions, flow constraints in the pipework, including those forced by a well partly infiltrating a ground water or other elements of the finalization geometry, are not in this description, they are either set up by structure to accomplish an objective or do not make an appearance in usual indicators of formation damage like skin. Solids clogging, clay-particle enlargement or scattering, saturation variations, wettability turnaround, emulsion stoppage, or mutual precipitation of the soluble salts are some of the additional processes that cause the processes. The process can be quantified using the below equation:

Formation damage, on the other hand, is measured using the skin factor, S, a dimensionless pressure decreases as a result of a flow restriction near the wellbore. The following equation is used to express it.

![]()

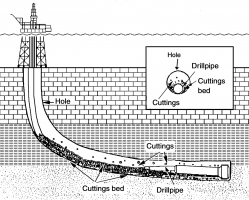

Hole Cleaning

The procedure refers to the ability of a drilling fluid to carry and keep drilled particles throughout the drilling operation. As per the study, drilling at an inclination angle more than three hundred degrees from vertical could cause challenges with trimmings removal that are not seen in vertical wells. The production of a stationary cuttings or a moving bed, as shown in the diagram below, is a significant issue when the flow rate for a certain mud rheology falls under a threshold level.

Conclusion

Drilling engineering is a sensitive process that requires careful planning and execution. The exercise is characterized by various challenges that may result in contamination of both the material being mined and the environment. Therefore, it is important for one to undertake the due procedure that will minimize such events from occurring. Understanding the structure of the surface from which the mining process will take place is important as it will determine the type of drilling to undertake. The choice of drilling will also depend on other factors, including the costs. Finally, one has to understand some of the common problems associated with the drilling process. This understanding helps the drillers to avoid making certain mistakes that may lead to significant wastages and unexpected losses. It also helps the researchers take appropriate precautions towards preserving the environment and protecting the ecosystem.

Works Cited

Funnell, Matthew. “Five Most Common Drilling Methods Used in Oil and Gas Exploration.” The Driller RSS, The Driller, 18 July 2018, https://www.thedriller.com/articles/90598-five-most-common-drilling-methods-used-in-oil-and-gas-exploration.

Hossain, M. Enamul, and Abdulaziz Abdullah Al-Majed. Fundamentals of sustainable drilling engineering. John Wiley & Sons, 2015.

Islam, M. Rafiqul, and M. Enamul Hossain. Drilling Engineering: Towards Achieving Total Sustainability. Gulf Professional Publishing, 2020.

Mitchell, Rober, and Stefan Miska. Fundamentals of drilling engineering. Society of Petroleum Engineers, 2011.

write

write