Introduction

In the past years, the smoke has been recognized as one of the major killers in a fire situation. This is because it can spread in the building more than fire. Staircases lobbies and elevators become smoke logged, inhibiting evacuation and firefighting activities. Occupants need to be aware of how fast smoke and fire can grow and the amount because such knowledge is significant in the evaluation of the design parameters of the smoke control system.

In a comprehensive structure, a smoke extraction system is essential. Its main objective is to reduce dangers in the event of a fire and reduce the chances of property destruction. These systems are divided into two categories;

In buildings, more than one fire protection system shall be provided. These systems are smoke and heat vent systems. However, based on much research. It is found that venting systems and sprinklers have some disadvantages and advantages. Hence fire protection engineers must consider the interaction between them.

When a building is under fire, the production of hot smoke is one of the major hazards to endanger the lives of the occupants. Inhalation of smoke and hot gasses is a lethal factor due to exposure to high temperatures, toxicity, and suffocation. Heat and smoke systems improve visibility by eliminating hot air and smoke. And this facilitates the evacuation of occupants, and operations conducted by the firefighters are also enhanced.

These vents again help in the reduction of temperatures and concentration of harmful gasses during the event of a fire. This as well facilitates evacuation of the occupants and indication of the fire location in the building.

Interaction of the smoke venting system, and sprinkler system. According to the experiment investigation, smoke vents shall not detriment the performance of the sprinkler system. The experiment also showed that a smoke ventilation system would affect the first sprinkler if the fire occurred near the smoke vent.

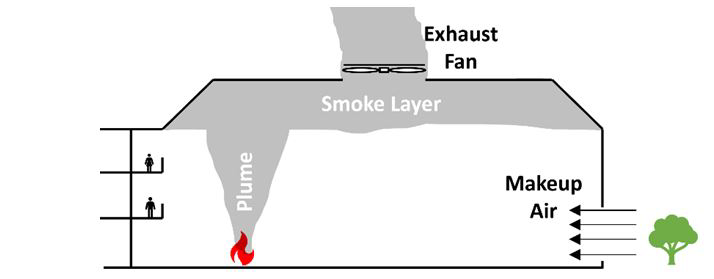

For this report, two types of smoke management systems are used. One is the use of mechanical exhaust combined with natural ventilation. The goal of the system is to keep the smoke layer above the highest occupancy level. Other management systems are discussed slightly with their formulas.

The design

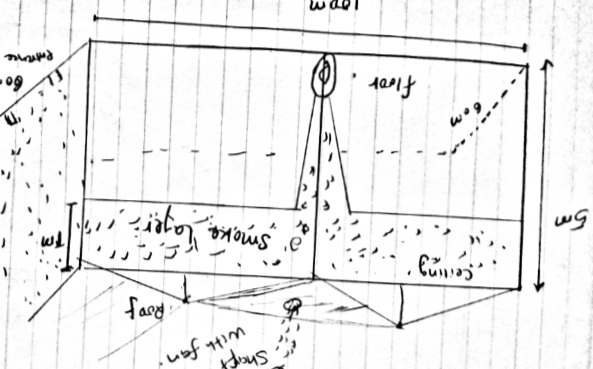

Hand drawn design

The regulation governing the design of smoke systems.

According to the CIBSE guide, fire and safety engineering entails smoke control as one of the responsivities of a fire engineer. It also states that fire engineering provides a route toward successful smoke control. Most of the formulas used are from CIBSE.

Other regulations Governing fire safety are also used in the report. This means that more than one regulation document was used for the design. They are cited in the reference section together with the other literature.

Scope of the study

Design a smoke Extraction system and analyze it

Description of the compartment

- Room dimensions (length 100m, width 60m, and Hight of the room 5m)

- The size of the fire is assumed to be

- Hight of the smoke layer is taken to be

- Assumed parameters

- Ambient temperature = 21 degrees Celsius

- Density of air 1.2Kg/m3

- Specific heat of air = 1.92

- Fire growth = 0.0444KW/s2

- Virtual source above base of fire = 0

The proposed fire used for any design is characterized by different heat output in the first stage of fire development. At the first stage of fire development, it is assumed that the fire is well ventilated. And the rate of bunning is characterized by different fire classes.

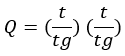

t-squired fire is given by the following equation

Where the value tg represents the growth of the fire

And for the design purpose, it is assumed that the flashover does not occur because sprinklers are to be installed. This is because sprinklers are designed to operate at temperatures less than 600 degrees.

Other assumptions as a designer, I have two choices. The first one is to assume that steady-state fire conditions are available. Therefore, I have provided natural ventilation for the compartment. Also, assuming that the fire is developing continuously meaning the rate of heat should increase with time. On the assumption that all the conditions for the development of fire are available, there will be a large area of natural vents. Another assumption for the design is that 60% of the total heat produced is converted to plume, and there are no heat losses.

Calculations, Analysis of factors affecting smoke management

Mechanical and natural smoke shafts are part of the smoke control system to protect corridors and pathways and keep them free from smoke. Therefore, during design, corridors should be ventilated. These are the basic parameters mentioned in the CBICE guide. The symmetry and geometry of the smoke shaft depend on the construction specifications. One of the specifications is clear that vents should be constructed using fire-resisting materials.

The proposed smoke control system will automatically activate itself in the event of a fire, and the primary means of activation of the system is y the use of an activation alarm. These sensors are to be located in different spaces on the building. The use of sensors to activate the mechanical smoke system is advantageous because the system will be activated at the early stages. These detectors will also be installed at the HVAC systems of the chamber.

The proposed smoke system will also have a remote-control chamber that will be located at one of the buildings. The center where the remote control will be placed is near the exit door, where it can be accessed easily by the firefighters.

Movement of the smoke in the structure

The main driving force of smoke in the building is the stack effect, expansion buoyance HVAC system, and wind. That means that when there is a fire accident in the building, smoke movement will be caused by these driving factors, each of the mentioned forces is analyzed for the proposed system.

Stack effect: let’s say, for instance, when it is cold outside, there is an upward movement of air within the building shafts, such as the elevators and staircase. This is known as a normal stuck effect. The atmosphere in the building creates current because it is warmer and less dense air on the outside. In our case, this effect is not of much consideration given that the stricture is not that tall.

On the other hand, when the air outside is warmer than the air in the building, there is a downward flow of air, and this phenomenon is known as the reverse stack effect.

Calculation’s formula

![]()

The value of;

- P0 = air density outside

- P1 = air density outside

- h = distance from the neutral plane

- and lastly, g = the gravitation constant

arrows show the movement of air

Buoyance

smoke from the fire has a high temperature compared to the temperatures inside a building environment, and this results in pressure differences between the fire compartment. This results in pressure difference between the fire compartment and its surrounding. In this case, Buoyance is not much large, unlike tall buildings. Our design consists of doors and windows. This makes this force less significant. Because smoke will travel to the door away from the fire, the temperature of the smoke drops due to heat transfer.

Expansion of gasses

moreover, the energy released by the fire causes smoke movement due to expansion. If we assume the compartment has only one opening, for instance, air will flow to the fire, and smoke will flow to the compartment.

Neglecting the mass of the fuel, the ratio of the volumetric flow rate of air into the compartment is equal to the absolute temperature of the smoke living in the fire compartment divided y the air into the compartment.

![]() .

.

Vo = is the volumetric flow of air outside

V1 = is the volumetric flow of air inside

T0 = is the temp of air getting out of the compartment

T1 = the temperature of air getting into the compartment

Wind

in most cases, the wind increases the movement of smoke in the building. In building and construction, wind and humans are life loads. Meaning the pressure exerted on the building by wind is inconsistent

the pressure exerted by the wind on the structure is given by the following formula.![]() , where;

, where;

- p = the pressure of the wind

- pk = dimensionless pressure co-efficient

- d = density of air

- v = the velocity of the wind

Assuming that the velocity of wind is 15m/s, it means that the pressure exerted to the structure at the time is 117pa, with a pressure coefficient of 0.8. Let’s say our design is loosely designed, which means the impact of the wind will be high, making smoke spread faster in the structure. However, when the design is the tight impact of the wind on the structure will be less.

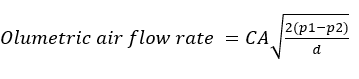

The flow rate of air through the openings is directly proportional to the pressure difference across the path raised to the power of n. in most cases, n = 0.5.

Therefore

Where;

C = flow co-efficient

A = flow area

![]() pressure deference

pressure deference

D = density of air

The value of C is estimated to be from 0.6 to 0.7, and air density remains the same. The flow area is the same as the cross-section of the openings.

The fan in the system is essential, considering that smoke movement depends on velocities and pressure differences. A fan has the following advantages.

- Smoke flow is less dependent on the barriers.

- Buoyance and wind are also less likely to influence the movement of the smoke.

- And lastly, a smoke control system can be designed at the corridors and door ways’

Airflow

the rate of airflow through the openings can be used to control the movement of smoke on the corridors and doorways. This is possible when the air flowing through the openings is above the critical velocity.

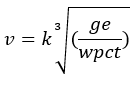

To find the critical velocity of the design to stop smoke movement in the structure.

Given that;

- V = velocity of air required to stop the smoke flow

- e = energy release

- w = width of the corridor

- c = specific heat

- gravitation force

- k constant of 1

this formula is used when the source of the fire is on the corridor

Assumption

Assuming our design has a corridor of measurement 2.4m, the fire energy release rate is 0.5112kW, and the velocity of air is 1.4m/s, this will give us a critical velocity of 3.5m/s, which is a perfect rate of airflow according to the regulations. Regulations state that airflow at the corridors should be higher than 1.5 meters per second.

How to ensure good qualitative smoke control.

We are designing a smoke extraction system. Some factors have to e considered by the fire safety engineer. And one of the factors is pressure difference, occupancy type and characteristics, evacuation plan, building security provisions, potential fire threats in the structure, external wind velocity, building characteristics such as the size of the windows doors, among others.

spread of smoke and toxic gas materials in the event of fire depends on;

- Building characteristics

- Occupant characteristics

- Environmental characteristics.

- Rate of heat release

- Rate of smoke production

- Rate of carbon IV oxide production

- Smoke and hot gas temperature

- Smoke and optical density

- Time of evacuation and fire barriers

The main objective of installing a smoke control system in the building is to reduce deaths caused by fire. And injuries from smoke. But another important goal is to reduce property loss. In theory, a smoke control system can be designed either to provide a safe escape route or safe refuge area or do both. It is clear that the proposed smoke control system can meet its goal. However, how small. Therefore, smoke management is important in a building.

Smoke management is a method that can be used to modify smoke movement for the advantage of the firefighters and occupants. For instance, the use of barriers, smoke vents, and smoke shafts, as mentioned above, have an impact on smoke movement. in modern days, fans can be added to the system, and with a fan, the system depends on the pressure difference and air velocity to control the movement of smoke to the next compartment.

From the first section of the question, we can comfortably mention the principles of smoke control. Smoke can be controlled using floors, walls, and others. There are two basic principles of smoke control, one is airflow, and the other is referred to as pressurization. To ensure good smoke control in the building, the above-mentioned effects must be put into consideration and analyzed.

It is clear that the smoke control system should not be easily controlled by external factors. Meaning the movement of smoke in the event of fire should always be under the control of the smoke system. This is the only way to ensure the safety of the occupants in the building. Therefore, using an exhaust fan on the system is vital to creating a mechanical current. With exhaust fan factors such as flow of air and pressure are under control.

Conclusion

In conclusion, the above-drawn and discussed smoke management system utilizes pressure and airflow. To control the movement of smoke in the building, Natural ventilation, and a mechanical fan is used at the exhaust. Smoke sensors are installed to activate the system. Finally, factors that will determine the effective working of the system are discussed.

References

Application of fire safety engineering principles to the design of buildings. (n.d.). doi:10.3403/02649282BS en 12101-3. (2015, December 27). Retrieved from https://fdocuments.in/document/bs-en-12101-3.html

Decheng, L., & Zegong, L. (2014). Study on numerical simulation of smoke control mode in the smoke-proof staircase of high-rise buildings. 2014 7th International Conference on Intelligent Computation Technology and Automation. doi:10.1109/icicta.2014.172

Donegan, H., Shields, T., & Silcock, G. (1989). A mathematical strategy to relate fire safety evaluation and fire safety policy formulation for buildings. Fire Safety Science, 2, 433-441. doi:10.3801/cafes.fss.2-433

Fire dynamics and hazard calculations. (2015). Performance-Based Fire Safety Design, 91-100. doi:10.1201/b18375-9

Fire safety in the design, management, and use of buildings. Code of practice. (n.d.). doi:10.3403/30314118

Fire. (2021). Process Safety Calculations, 361-442. doi:10.1016/b978-0-12-823516-4.00007-8

Frank, C., Pitt, H., & McKee, B. (2007). Laminar flow air: A comparison of operating room air purity in rooms equipped with laminar flow air versus no laminar flow air. American Journal of Infection Control, 35(5), E59. doi:10.1016/j.ajic.2007.04.059

Jones. (2011). CIBSE review of energy benchmarks for display energy Certificates. CIBSE Technical Symposium 2011. doi:10.3943/2011.0022

Lee, H. (n.d.). Fire safety management and property management in Hong Kong. doi:10.5353/th_b4834209

Seyam, S. (2018). Types of HVAC systems. HVAC System. doi:10.5772/intechopen.78942

Smoke control systems. (2021, February 5). Retrieved from https://www.nfpa.org/News-and-Research/Publications-and-media/Blogs-Landing-Page/NFPA-Today/Blog-Posts/2021/02/05/Smoke-Control-Systemsundefined. (n.d.). doi:10.3403/01095521

write

write