Abstract: The developments in precision manufacturing and processes have led to the developments in the high-power and ultra-short pulse solid-state laser devices applicable in manufacturing and process that rely on high precision and high work rate. The concepts have led to the development of diode-based laser pumps that deliver high-power and quality beams. High-power solid-state lasers have led to the realization of lasers with average power ranging from 100 kW. This paper focuses on advanced high-power solid-state lasers and technologies such as chirped pulse amplification, optical parametric amplification, and beam combination used to implement high-power solid-state lasers. The study also analyzes the operation principles, emission stimulation, and non-linear frequency conversion. Further, the study discusses different high-power solid-state laser applications and compares different architectures.

Main Text: This report shows different approaches for improving laser performance regarding average output power and pulse rate. The paper has the introduction, principles, application, scheme comparison, future outlook, and conclusion sections. The introduction provides the background and definition of high-power solid-state lasers and the leading technologies and media used in their implementation. The principal section describes the principle of operations of high-power solid-state lasers. Further, the application and example work section discusses a sample of different technology applications. The scheme comparison section compares the performance of different technology architectures.

Introduction

Advanced high-power solid-state laser technology refers to developing and implementing lasers that can generate high-energy pulses or continuous beams for various applications, including material processing, scientific research, and defense applications. Solid-state lasers use a solid-state gain medium, such as a crystal or glass, to amplify and emit light (Boulanger et al., 2017). High-power laser technologies are high-brightness laser technologies for laser generation that applies solid-state materials as a gain media. The lasers are divided into slabs, optical fibers, and sheets depending on the gain media. Fiber and slab lasers have become popular in high-brightness lasers using solid-state lasers due to their high-power output (Tang et al., 2020). For instance, slab lasers can provide an output of 100 kW, while a single fiber laser can output 20 kW.

Many technologies, such as chirped pulse amplification, optical parametric chirped pulse amplification, master oscillator power amplifier, and beam combination, have been proposed for high-power solid-state laser technology. In addition, multiple media such as diamond, Nd: YAG, optical fiber, Yb: YAG, and Nd: YVO4 have been used to achieve high-power lasers. Initially, high-power lasers used to be neodymium and glass lasers (Brauch et al., 2022). The neodymium rod lasers were pumped by discharge lamps, which emitted a high laser spectrum from NIR to UV and resulted in 2-3 % electrical-to-optical laser efficiency. The introduction of solid-state technology as active material replaced rod or slab lasers with diode lasers, resulting in higher absorption efficiency and reduced quantum defects between the laser photons and the pump (Boulanger et al., 2017). High-power lasers, however, suffer quantum defects, the temperature difference between the energy of the laser photons and the pump. Maintaining the effectiveness of high power involves keeping the active medium temperature at a reasonable level to reduce heat produced by the laser process and heat generation.

Principle

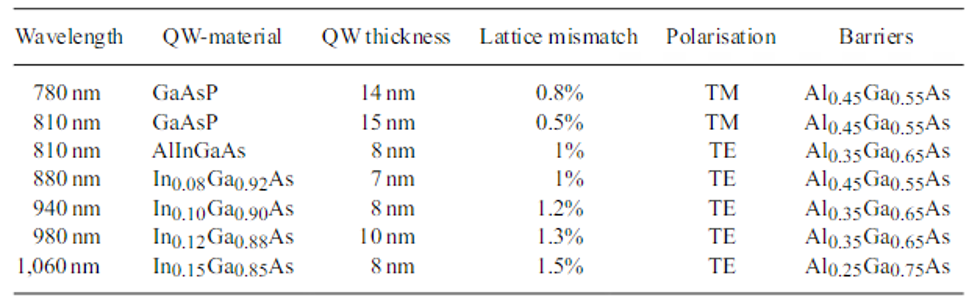

The principle of advanced high-power solid-state laser technology is based on the stimulated emission of photons by an active medium typically made up of a solid crystalline material such as yttrium aluminum garnet (YAG) or neodymium-doped yttrium aluminum garnet (Nd: YAG). The active medium is excited by a pump source, such as a flashlamp or diode laser, which causes the electrons within the medium to be excited to a higher energy level (Brauch et al., 2022). As the electrons return to their original state, they emit photons in a process known as stimulated emission. These photons are then reflected back and forth between two mirrors within the laser cavity, amplifying the light and producing a coherent beam of laser light. The threshold of laser operation is obtained if the gain of the optical resonator of the feedback system compensates for the losses in the system (Behringer, 2007). Quantum wells in modern and advanced high-power lasers achieve the gain and the laser wavelength. The table below shows the different properties of quantum wells from different materials.

Table 1. Different quantum well properties and barrier layers for diode lasers emitting between 780 nm and 1060 nm.

The energy of the generated photons in the laser depends on the differences in the solid-state semiconductor’s energy levels, and the band gap sizes determine the wavelength of the lasers and, thus, the composition of the solid-state crystal. High-power solid-state lasers emit at 0.7 to 1.0-micrometer wavelength.

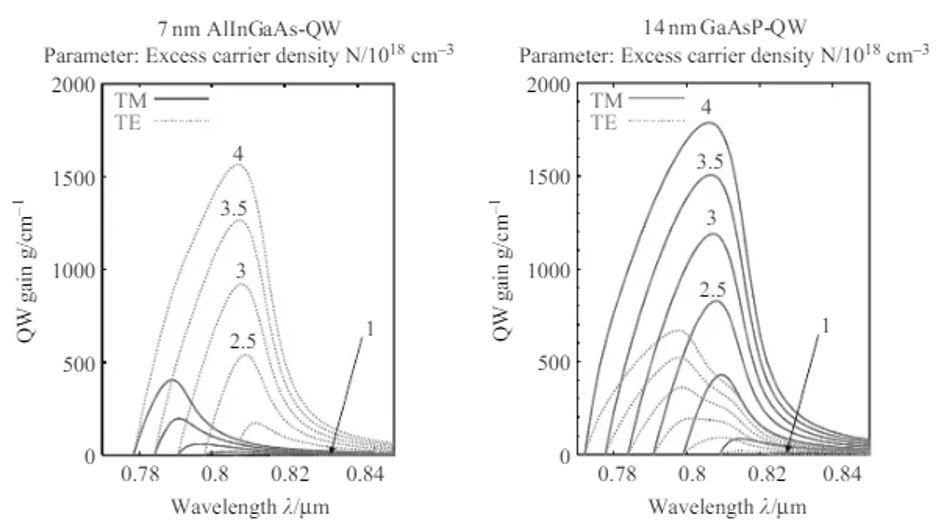

The crucial optical pumping devices for the Nd-based solid-state lasers are devices emitting at 808 nm. The devices can be produced from strained GaAsP and InAlGaAs quantum wells that produce effective wavelengths (Behringer, 2007). The gains for the two types of materials are shown in the figure below.

Figure 1. The Solid-state laser optical gains at different excitation levels and wavelengths for the GaAsP and InAlGaAs quantum wells.

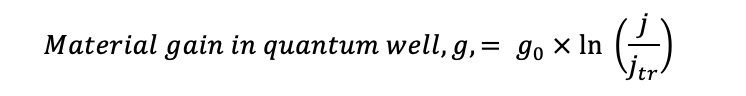

For solid-state optical lasers, the optical gain in the active material can reach values greater than 1000 per centimeter as only a tiny portion of the material is confined in the quantum well. The high laser’s gains compensate for light extraction and high mirror losses. The material gain of the quantum wells is expressed as follows.

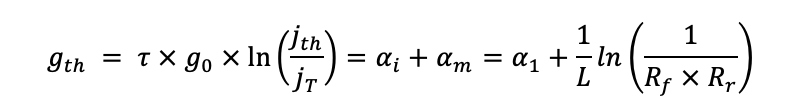

Where j is the applied current to the device, jtr is the transparency current, and g0 is the reference gain. Both the transparency current and reference gain depends on the material’s thickness and the QW’s strain value (Behringer, 2007). The threshold gain is expressed as follows. The current density compensates for the mirror losses and internal loss at the gain.

Where is the QW confinement factor, Rr and Rf are the rear and front coupling mirror’s reflectivity, is the internal losses, and L is the resonator length.

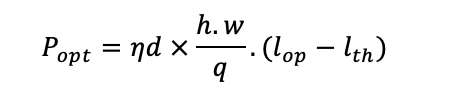

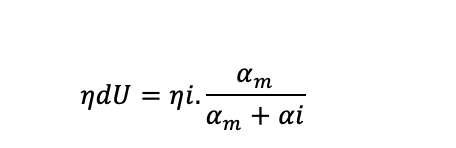

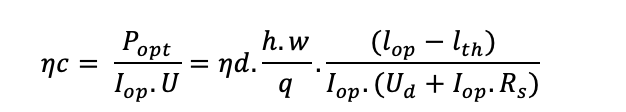

The output power can be expressed in terms of the pumping current as follows

But,

Where is the slope efficiency, is the mirror loss, is the internal losses, is the internal efficiency (Behringer, 2007). Conversion efficiency is determined in the designs of high-power solid-state lasers from small-footprint semiconductors. Conversion efficiency is the ratio of the optical output power to the electrical input power, expressed as follows.

In advanced high-power solid-state lasers, using high-powered diode lasers as the pump source has enabled the development of more efficient and compact laser systems. Additionally, advanced cooling systems such as cryogenic or water cooling have enabled these lasers to operate at higher power levels without thermal damage to the active medium or surrounding components.

Another fundamental principle of advanced high-power solid-state laser technology is non-linear frequency conversion techniques such as harmonic generation or parametric amplification. The non-linear optical frequency conversion results from matter’s response to the interaction with the intense electric field. For effective frequency conversion, there is a need for energy and momentum conservation. In the non-linear frequency conversion process, there is a compromise between the total energy efficiency and the phase-matching bandwidth, which are directly and inversely proportional to the thickness of the material (Dogadov et al., 2022). These techniques enable the laser beam to be converted into higher or lower frequencies, allowing for a broader range of applications such as material processing, medical procedures, and scientific research.

An example of non-linear optical frequency conversion is the Optical Parametric Amplification (OPA). The OPA is a second-order non-linear crystal involving energy transfer among beams at different frequencies. In OPA, energy is transferred from high to low-intensity beams, and the optical signal is amplified (Ciriolo et al., 2017). The parametric amplification uses non-linear media as an intermediate during the interaction of the pump, signal, and idler waves, unlike in the case o the stimulated emissions that relied on real energy levels during the resonance process.

Application and Example Work

Army Weapons

High-power solid-state lasers are effective strategic military weapons that can be space or ground-based to intercept enemy ballistic missiles and satellites. The high-power lasers can generate up to 100 kW power that can be used as anti-aircraft and anti-missile systems. Fiber lasers are recommended for their high power and long range for high-power laser weapons. Additionally, the technology is effective on its excellent weight, size, and power ratio and is therefore considered a portable laser weapon. Fiber lasers are also ideal as they require less power to maintain high-quality beams. Due to the high cost of the technology, it can be applied in exceptional cases, such as the protection of navy vases, aircraft carriers, and high-level command posts (Lyubomir, Edmunds, & Risham Singh, 2021). The technology also requires special needs such as laser fuel storage, personal safety, environmental factors, cooling, and pointing and tracking requirements. An example of a high-power solid-state laser weapon is Boeing’s HEL-MD laser. The laser is a 10-kW powered, one-micron wavelength designed to destroy mortars, artillery, rockets, and drones.

Selective Laser Melting

High-power laser radiations are used for selective remelting and polishing. The technology produces parts from a single material by remelting the material along the laser beam track. The technology is applied in producing finished products such as dies and molds and manufacturing three-dimension metals, ceramics, and plastics (Poprawe & Schulz, 2003). In the production line, structured parts are produced layer by layer from remelted powder within a short time while maintaining and perfecting the quality of the manufactured parts.

Marking on the inside of the Glass

High-power laser technology is used to mark the inside of transparent materials due to their high power and frequency of operation. For instance, Innoslab can reach an output power of 800 kW at high-frequency conversion (Poprawe & Schulz, 2003). The high power and quality beams near the diffraction limits allow the lasers to be used in marking the inside of the transparent materials. The high-power lead to local absorption and optical breakdown leading to micro-cracks in the material.

Cleaning

The technology can be used in intensive and pulse laser radiation cleaning materials. The cleaning method is superior to conventional and mechanism cleaning as the ablation depth can be predefined. Additionally, the technology provides low absorption by the material leading to the removal of coating and base structure without damaging the entire structure (Poprawe & Schulz, 2003). For instance, the method has been used in cleaning lead frames and pylons for power transmission.

Scheme Comparison

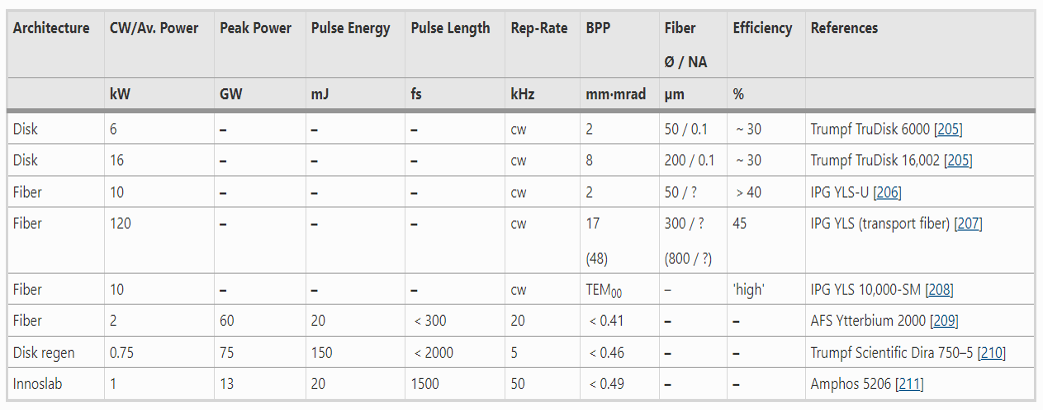

The table below compares the average and peak power, pulse energy and length, efficiency, and frequencies of different high-power solid-state architectures.

Table 2. Comparison of disk, fiber, and Innoslab laser systems.

Future Outlook

The above project provides solutions to high-power and quality beams that have been applied in industries, military machines, and weaponry. However, there is a need to develop ultra-short and high-peak power solid-state lasers that are suitable for application in cutting metal sheets and circuit board welding (Market Projects, 2022). Different high-power solid-state lasers that can reach 100 kW and 200 kW is the new trend, and using a Direct Diode laser can implement this. Additionally, ultra-short pulse lasers will be required for precision machining.

Conclusion

This report summarized the advanced high-power solid-state lasers. The summary involves an analysis of the operation principles. The high-power solid-state laser operation principle is divided into; emission stimulation with the application of energy levels and non-linear frequency conversion, which is due to the response of matter to the interaction with the intense electric field. In the stimulated emission operation principle, the solid-state laser’s gain depends on the quantum well’s properties, such as thickness, material, and wavelength. These techniques enable the laser beam to be converted into higher or lower frequencies, allowing for a broader range of applications, such as military weaponry, surface cleaning, and marking transparent materials. The report also compared the performance of different solid-state architectures and discussed the future outlook of high-power solid-state devices and technology.

References

Behringer, M. (2007). High-power diode laser technology and characteristics. High Power Diode Lasers: Technology and Applications, 5-74.

Brauch, U., Röcker, C., Graf, T., & Abdou Ahmed, M. (2022). High-power, high-brightness solid-state laser architectures, and their characteristics. Applied Physics B, 128(3), 58.

Boulanger, B., Jiang, S., Mirov, S., Nilsson, J., Petersen, A., Rotermund, F., … & Taira, T. (2018). Feature issue introduction: Advanced Solid-State Lasers 2017. Optics Express, 26(8), 11018-11024.

Tang, X., Wang, G., Liu, J., Geng, L., & Jiang, D. (2020). Development of high-brightness solid-state laser technology. Strategic Study of Chinese Academy of Engineering, 22(3), 49-55.

Dogadov, O., Trovatello, C., Yao, B., Soavi, G., & Cerullo, G. (2022). Parametric Non-linear Optics with Layered Materials and Related Heterostructures. Laser & Photonics Reviews, 16(9), 2100726.

Ciriolo, A. G., Negro, M., Devetta, M., Cinquanta, E., Faccialà, D., Pusala, A., … & Vozzi, C. (2017). Optical parametric amplification techniques for generating high-energy few-optical-cycles IR pulses for strong field applications. Applied Sciences, 7(3), 265.

Lyubomir, L., Edmunds, T., & Risham Singh, G. (2021). Applications of laser technology in the army. Journal of Defense Management, pp. 11, 210.

Poprawe, R., & Schulz, W. (2003). Development and application of new high-power laser beam sources. Riken Review, 3-10.

Market Projects. (2022, December). Future development trends of the Laser Processing Industry. Market Prospects. Retrieved May 8, 2023, from https://www.market-prospects.com/articles/future-development-trends-of-the-laser-processing-industry#:~:text=Ultra%2Dshort%20pulse%20and%20high,cost%20of%20ultrashort%20pulse%20lasers.

write

write